Diaphragm valve instruction manual, possible failures and elimination methods

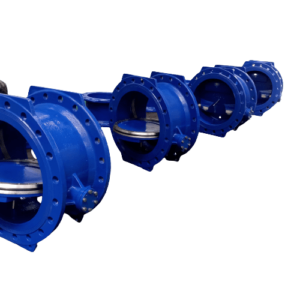

1. This valve is composed of valve body, bonnet, valve stem, valve disc, diaphragm and driving parts.

2. The opening and closing of the valve is achieved by rotating the hand wheel. When the handwheel is rotated clockwise, the valve will drop to cut off the passage; otherwise, the valve will open.

3. When the diaphragm valve is used in the water vapor pipeline with the working temperature ≤120℃, the material of the diaphragm should be heat-resistant rubber, and indicate it when ordering.