On the contrary, after a closed valve is suddenly opened, water hammer will also occur, called negative water hammer, which also has a certain destructive power, but it is not as great as the former.

Usually, when the valve is close to closing, the closing element is suddenly sucked into the valve seat, which is called the melting cylinder blocking effect.

The lock-up effect of the melt cylinder is caused by a low-thrust actuator. The actuator does not have enough thrust to maintain a position close to the valve seat, causing the sudden closing of the pump or the sudden closing of the valve, resulting in a water hammer effect. For control valves, in some cases, valves with quick opening flow characteristics can also cause water hammer.

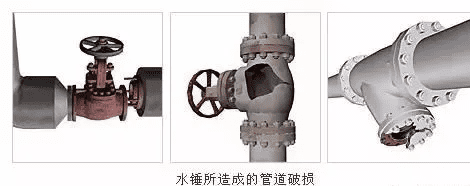

Although water hammer makes a lot of noise, the real damage is caused by mechanical failure. Because of the rapid change from kinetic energy to static pipeline pressure, water hammer can break through the pipeline or damage the pipe support and damage the pipeline joints. For valves, water hammer can cause severe vibration through the valve core, which may cause failure of the valve core, gasket or packing.

For valves, the way to prevent water hammer is to prevent any sudden pressure changes in the system.

Including slowing down the closing speed of the valve itself or providing a greater degree of tension and rigidity when the closing element approaches the valve seat. To prevent pressure fluctuations, the valve should be closed at a uniformly varying speed. In some cases, when the quick opening feature is used, it can be changed to an equal percentage feature. For control valves that must be throttled when approaching the valve seat, actuators with sufficient output thrust should be used, such as piston pneumatic actuators or hydraulic actuators, or special gaps should be set on the stroke sleeve of the manually rotating operator. Will reduce or prevent the blocking effect of the melting tank. A certain type of anti-fluctuation measures on the pipeline system can also reduce water hammer. Can use pressure relief valve or buffer barrel to complete. In addition, gas can be injected into the system. The injection of gas can reduce the density of the fluid and provide some compressibility to deal with any sudden fluctuations.