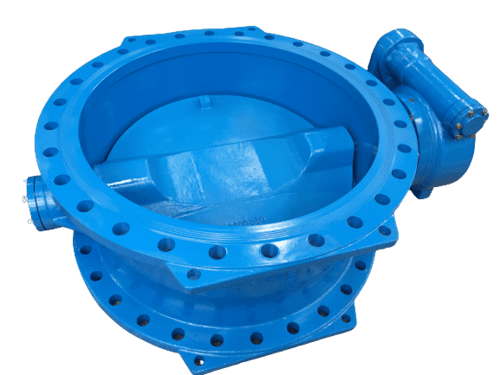

The double eccentric sealing butterfly valve adopts an eccentric structure design. The main structure of the valve is composed of valve body, butterfly disc, valve seat, valve stem and transmission mechanism. The valve seat adopts a detachable structure and can be based on the physical and chemical properties of different media. Corresponding corrosion-resistant, light-resistant, and aging-resistant materials are selected, which can be widely used in fluid pipelines such as water supply and drainage, sewage, construction, air conditioning, petroleum, chemicals, food, medicine, textiles, paper making, hydrpower, ships, metallurgy, energy systems, etc. Used as a regulating and intercepting device.

The double eccentric butterfly valve usually uses EPDM material as its sealing valve seat, and can also use metal sealing valve seat to expand its application in the high temperature field. However, the seal of the double eccentric butterfly valve with metal sealing seat is still a positional sealing structure, that is, the sealing surface of the butterfly disc and the seat is in line contact, so it cannot withstand high pressure, and it will inevitably lead to greater leakage when used in a high pressure system. Therefore, double eccentric butterfly valves with metal sealing seats should be avoided as far as possible in high-pressure or tight shut-off systems.

The triple eccentric butterfly valve takes advantage of the advantages of various valves and avoids the shortcomings of various valves, and has attracted more and more attention from users and designers. The standard caliber can reach 48 inches, and it can correspond to wafer, lugs, flanges, ring joints, butt welding, jackets, various structural lengths, etc., due to the room for material selection Very large, high and low temperature, various acids, alkalis and other corrosive media can also respond freely. Especially in the aspect of large diameter, it is constantly replacing the thick gate valve and ball valve in the shut-off valve.

So far, eccentric butterfly valves have been used in various important pipelines including oil and gas exploration, offshore platforms, petroleum refining, petrochemicals, inorganic chemicals, energy power generation and other major industrial fields such as process control. In actual engineering, if the working pressure of the system is not less than 1.0 MPa or in important parts that need to be opened frequently, eccentric butterfly valves can be used.