Material selection of diaphragm valve

Stem seal of diaphragm valve

The valve stem of the diaphragm valve is sealed by a soft and pressure-bearing diaphragm that connects the valve stem to the closing member. As long as the diaphragm does not fail, this seal can prevent any medium from leaking to the atmosphere through the valve stem. The shape of the diaphragm can be a round cap shape or a bellows shape. The material structure of the diaphragm. Depending on the application, it can be made of rubber elastomer and plastic.

The round cap-shaped diaphragm has a large non-compensation area for medium pressure, so the valve stem must overcome the corresponding high medium load. Therefore, the round cap diaphragm is only restricted to small-diameter valves. At the same time, since the deflection of the round cap-shaped diaphragm is limited, it is only suitable for valves with a small opening height.

On the other hand, the bellows-shaped diaphragm has a small non-compensation area for medium pressure, and the corresponding medium load transmitted to the valve stem is relatively low. This allows it to be used in larger-diameter valves. In addition, it is also suitable for opening heights of various valves.

In order to prevent any obvious leakage in the failed diaphragm from venting to the atmosphere, in addition to the diaphragm seal, the stem seal of the diaphragm valve is also equipped with a double stem seal similar to a compressed packing.

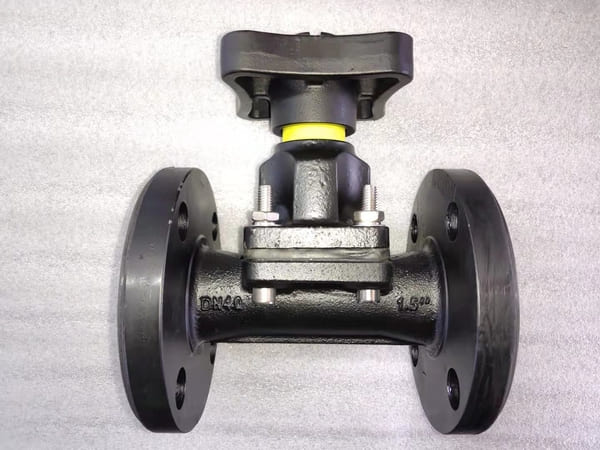

STABLE diaphragm valve products are classified into British standard diaphragm valve, American standard diaphragm valve, rubber-lined diaphragm valve/fluorine-lined diaphragm valve, straight-through rubber-lined diaphragm valve, weir-type rubber-lined diaphragm valve, British standard pneumatic diaphragm valve, British standard pneumatic lining Rubber diaphragm valve, stainless steel diaphragm valve, no rubber diaphragm valve.

Material of diaphragm valve

(1) Valve body

Diaphragm valve body can use different materials, such as DI, WCB, CF8, CF8M, etc. The simple valve body type lined with various anti-corrosion materials, such as rubber elastomer, fluoroplastics and enamel.

(2) Bonnet

Since the diaphragm shields the bonnet in the medium, the bonnet is usually made of cast iron, and its inner and outer surfaces are sprayed with epoxy coating resin or painting. If necessary, various other materials are also suitable for the bonnet.

(3) Diaphragm

The diaphragm can be used in a variety of different elastomers and plastics. STBALE VALVES recommends choosing the material of the diaphragm according to the given conditions.

The diaphragm material of the diaphragm valve is mainly rubber elastomer and FTFE. In this way, the diaphragm valve can be applied to almost any process medium by selecting the appropriate chemical compatibility material, without having to spend money on the upgrade of the working parts of the valve. The choice of diaphragm material is wide to suit a variety of chemicals. For severely corroded occasions, the diaphragm valve is made of stainless steel or PVC plastic, or lined with glass, rubber, lead, titanium or other materials.

1. Rubber diaphragm:

①The polymer material is bonded with the high-strength reinforced braid to ensure the best strength and durability;

②Consists of multiple rubber and nylon reinforcement layers;

③The connecting bolts are fixed by adhesives and mechanical anchors;

④The diaphragm is supported no matter it is in the open or closed position, thereby prolonging the life of the diaphragm.

2. PTFE diaphragm

①Double diaphragm structure-PTFE diaphragm and supporting rubber diaphragm on the back to improve the bending performance of the diaphragm;

②The bayonet connector can quickly install the diaphragm, while avoiding the load concentration point of the diaphragm, ensuring the longest service life;

③The advanced diaphragm extends the service life under wet chlorine and bromine media conditions.