Handling corrosive chemicals[^1] is a huge challenge. The wrong valve fails quickly, causing leaks, costly downtime, and safety risks. You need a solution that can withstand the harshest conditions.

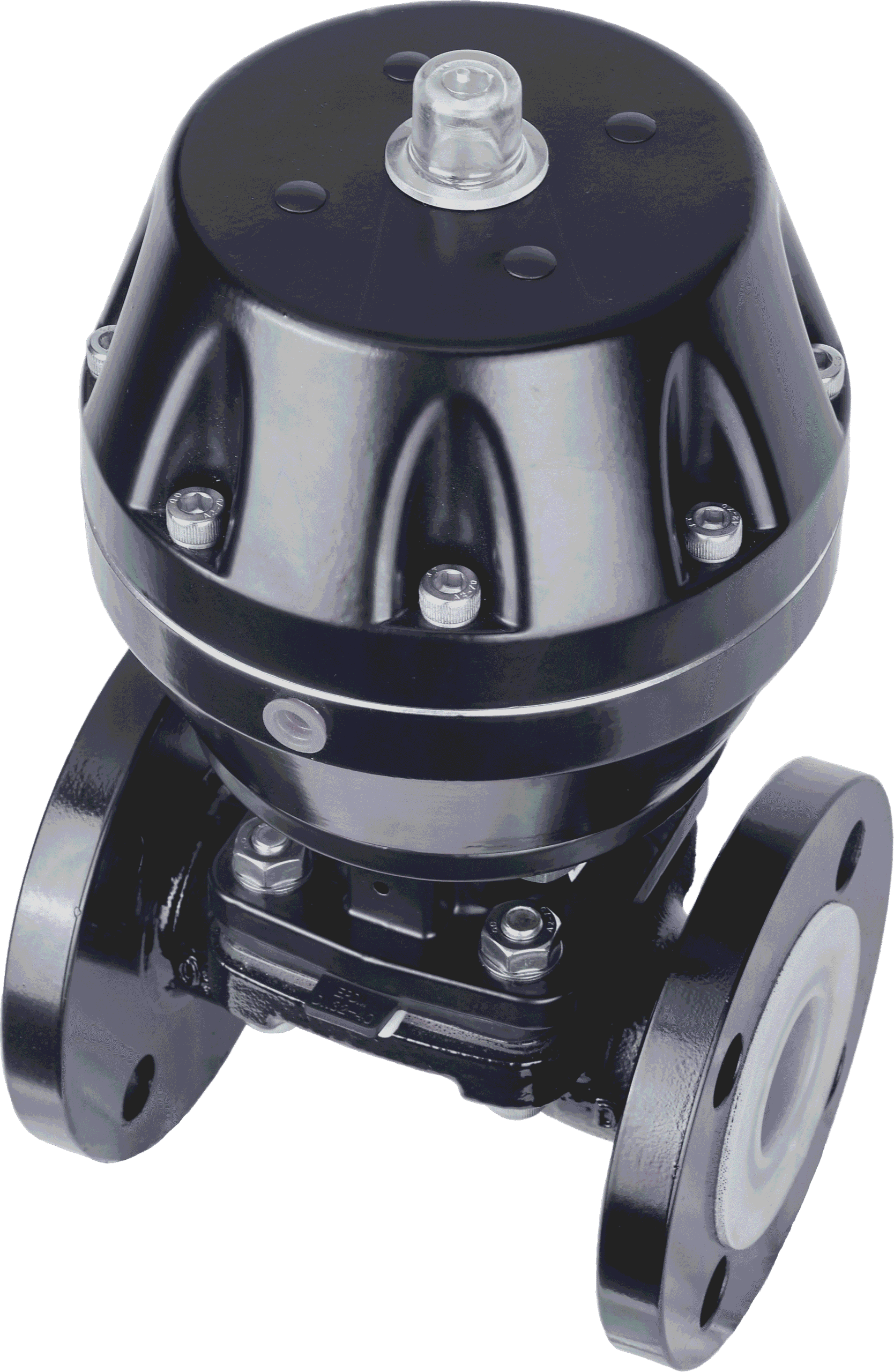

A PTFE-lined valve[^2] is a valve where all wetted surfaces are protected by a layer of Polytetrafluoroethylene[^3] (PTFE). This lining makes the valve extremely resistant to corrosive chemicals[^1], high temperatures, and contamination, making it ideal for aggressive industrial applications in chemical plants and processing facilities.

When I first started in the valve manufacturing business, I saw many clients struggle with standard valves in their chemical lines. They would replace them constantly, almost accepting it as a normal cost of doing business. But it doesn't have to be that way. The right material can change everything. That's where PTFE comes in. It provides a level of protection that other materials just can't match, and understanding its properties is key to building a truly reliable and safe fluid control system. Let's explore why this material is so important.

What Makes PTFE So Resistant to Chemicals and High Temperatures?

Your process involves aggressive media that destroys standard equipment. This leads to frequent maintenance, unexpected shutdowns, and worries about system integrity. You need a material that simply won't react.

PTFE's incredible resistance comes from its molecular structure. It is a fluoropolymer with very strong carbon-fluorine bonds. These bonds are extremely stable and non-reactive, making the material chemically inert to almost all acids, alkalis, and solvents, even at high temperatures.

The science behind PTFE is what makes it a superstar material for us in the valve industry. Think of it like a perfect shield. The fluorine atoms wrap tightly around the carbon backbone, leaving no room for other chemicals to attack. This is why we can confidently recommend it for some of the most corrosive applications out there. It’s not just about resisting one or two chemicals; it’s about providing broad-spectrum resistance. This inertness also means it can handle an impressive temperature range, typically from -200°C up to 260°C, without losing its properties. At our factory, we work with PTFE because we know it delivers the performance our clients depend on. Below is a simple comparison to show why it stands out.

Material Chemical Resistance Comparison

| Material | Acid Resistance | Alkali Resistance | Solvent Resistance |

|---|---|---|---|

| PTFE | Excellent | Excellent | Excellent |

| EPDM Rubber | Good | Good | Poor |

| Stainless Steel | Good-Poor | Excellent | Excellent |

| Cast Iron | Poor | Good | Good |

How Does a PTFE Lining Enhance Diaphragm Valve Performance?

You're concerned about valve lifespan and process purity. Abrasive slurries or sticky fluids can cause valve failure, while material leaching can contaminate your final product. You need a reliable, clean solution.

A PTFE lining creates a smooth, non-stick, and chemically inert barrier between the process fluid and the valve body. This prevents corrosion of the valve, reduces friction, eliminates product contamination, and extends the valve's operational life significantly, even in demanding cycles.

Over the years, I've seen firsthand how a well-applied lining transforms a standard valve body into a high-performance machine. At our facility, we use a mechanical application process for our PTFE linings. This ensures the lining is seamless and perfectly bonded to the cast iron or ductile iron body. The result is a smooth, flawless internal surface. This smoothness is critical. It not only prevents media from sticking and clogging the valve but also ensures a clean, non-contaminating flow path, which is vital in industries like pharmaceuticals and food processing. The durability of the PTFE means the valve can handle millions of cycles without the lining degrading. This translates directly to less maintenance and greater peace of mind for our clients.

Key Benefits of PTFE Linings in Diaphragm Valves

| Feature | Advantage | Impact on Your Operation |

|---|---|---|

| Chemically Inert | Prevents corrosion and contamination | Protects valve investment; ensures product purity. |

| Non-Stick Surface | Reduces friction and material buildup | Minimizes clogging and pressure drop; improves flow. |

| Wide Temperature Range | Performs in extreme hot or cold | Increases application versatility and reliability. |

| Durable & Seamless | Resists wear and tear | Extends service life; reduces maintenance downtime. |

Why Is PTFE Used in Pneumatic and Three-Way Diaphragm Valves?

Automated systems and complex flow paths present unique challenges. Pneumatic valves cycle frequently, causing wear, while three-way valves must reliably direct different, often corrosive, media without cross-contamination.

PTFE is ideal for pneumatic valves[^4] because its durability withstands constant cycling. In three-way diaphragm valves[^5], its chemical inertness is critical for handling and separating different corrosive fluids without degradation or cross-contamination, ensuring system integrity and precise control.

When a client needs to automate a process, especially in a chemical plant, I often recommend our pneumatic diaphragm valves with PTFE components. The actuator on a pneumatic valve can open and close it thousands of times a day. A weaker material would quickly fail under this stress. PTFE's toughness and low-friction surface ensure it can handle this repetitive motion smoothly and for a very long time. Similarly, for systems requiring diversion or mixing of fluids, a three-way diaphragm valve is the answer. Here, the PTFE lining and diaphragm are essential. They create a perfect seal and ensure that, for example, an acid in one port doesn't corrode the valve or mix with a base in another port until intended. This level of control and reliability is exactly what engineers and plant managers need to run their operations safely and efficiently.

PTFE Application in Specific Valve Types

| Valve Type | Key Challenge | How PTFE Solves It |

|---|---|---|

| Pneumatic Diaphragm Valve | High-frequency cycling and wear | PTFE's durability and low friction reduce mechanical stress. |

| Three-Way Diaphragm Valve | Directing multiple, often corrosive, fluids | PTFE's inertness prevents cross-contamination and corrosion. |

| Manual Diaphragm Valve | Handling aggressive media with reliable shutoff | PTFE's resilience ensures a tight, leak-proof seal over time. |

What Industries Benefit Most from PTFE-Lined Valves?

Your industry has specific, demanding requirements for fluid control. You need valves that not only perform under pressure but also meet safety standards and offer a good return on investment.

Industries like Chemical, Power Generation, and Wastewater Treatment benefit most from PTFE-lined valve[^2]s. They are perfect for handling corrosive acids, abrasive slurries, and high-purity water, where material resistance and reliability are absolutely critical for safety and operational efficiency.

We manufacture diaphragm valves for some of the toughest environments on the planet. Our primary clients are in sectors where a valve failure is not just an inconvenience—it's a major event. In the chemical industry, our PTFE-lined valve[^2]s are used for dosing everything from sulfuric acid to caustic soda. The PTFE lining is the only thing standing between these chemicals and the valve's cast iron body. In power plants, especially in flue gas desulfurization systems, our valves handle abrasive limestone and gypsum slurries day in and day out. The PTFE lining resists both the corrosion and the abrasion. For wastewater treatment plants, PTFE ensures that dosing chemicals like sodium hypochlorite are handled safely and without contaminating the water streams. In all these cases, PTFE provides the robust, long-term solution that our clients need.

Core Applications for PTFE-Lined Diaphragm Valves

| Industry | Common Application | Why PTFE is Essential |

|---|---|---|

| Chemical & Petrochemical | Acid and solvent transfer, dosing | Unmatched chemical resistance prevents leaks and corrosion. |

| Power Plants | Flue Gas Desulfurization (FGD), water treatment | Resists abrasion from slurries and corrosion from chemicals. |

| Wastewater Treatment | Chemical dosing (disinfectants, pH control) | Ensures safe handling of hazardous chemicals and prevents leaks. |

| Mining & Metallurgy | Ore slurry transport, pickling lines | Excellent wear resistance against high-solid-content media. |

Conclusion

In summary, PTFE-lined valve[^2]s provide superior chemical resistance, durability, and purity. They are the go-to solution for safely and reliably controlling corrosive and high-temperature fluids in demanding industrial systems.

[^1]: Discover best practices for safely managing corrosive chemicals in industrial settings. [^2]: Explore the advantages of PTFE-lined valves for enhanced durability and chemical resistance. [^3]: Learn about PTFE's unique properties and its wide range of industrial applications. [^4]: Learn about pneumatic valves and their critical role in automation. [^5]: Understand the applications and benefits of three-way diaphragm valves.