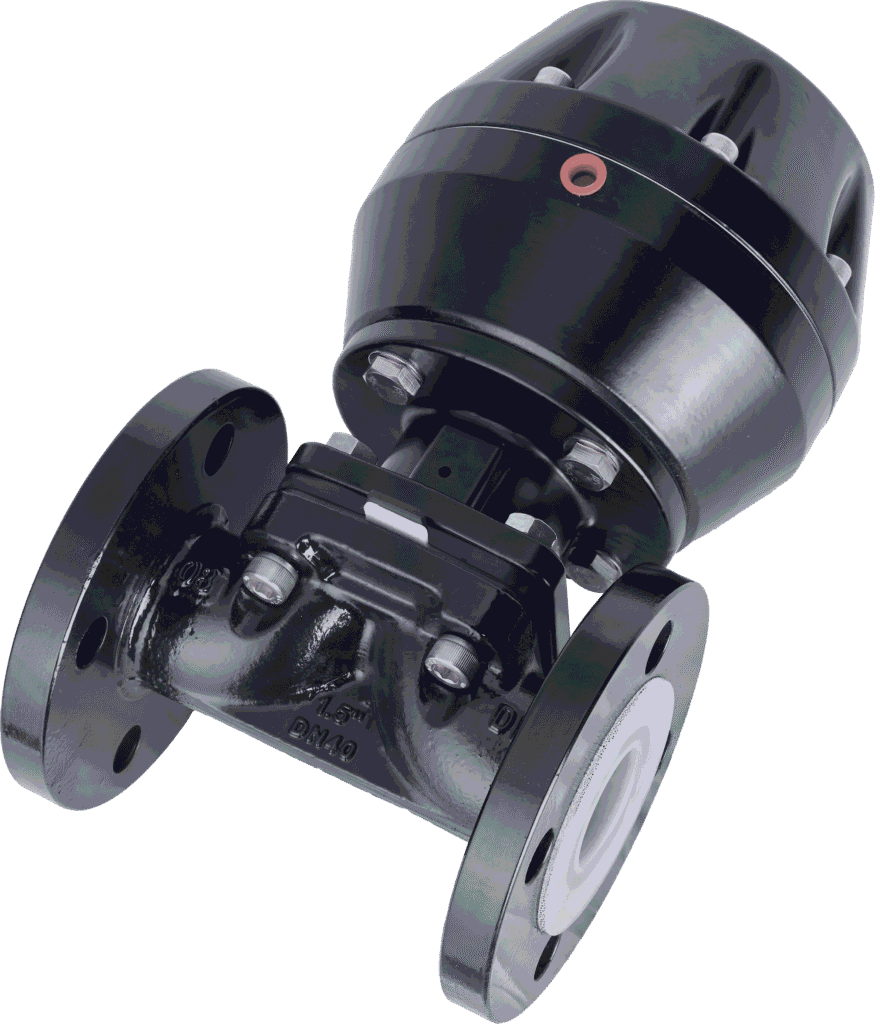

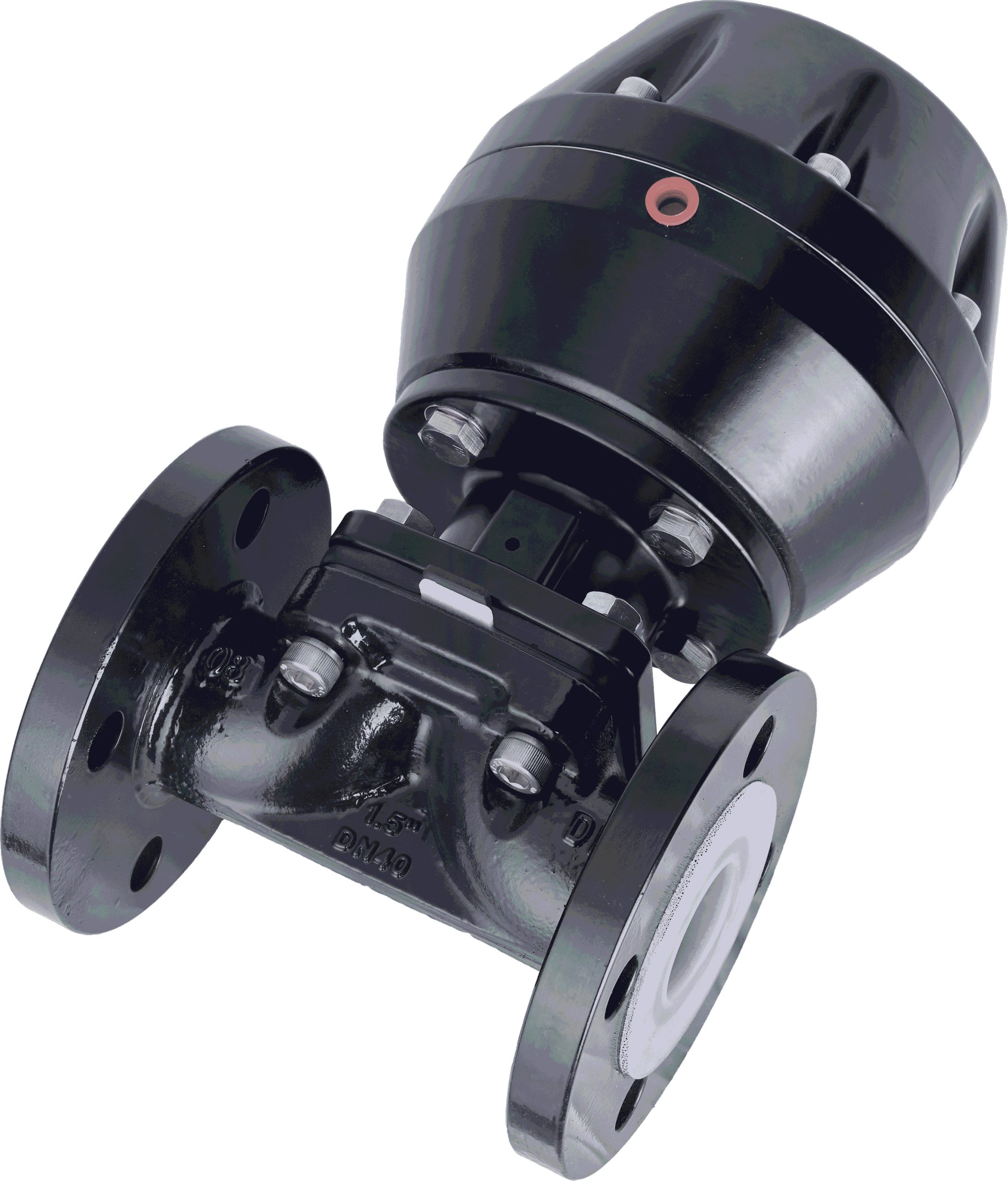

Tired of valve failures with corrosive fluids or slurries? This causes costly downtime. Pneumatic diaphragm valves[^1] are designed to handle these tough jobs, solving your most persistent flow control problems.

Pneumatic diaphragm valves[^1] excel in industries like chemical processing[^2], power generation[^3], wastewater treatment[^4], and mining. Their unique design makes them ideal for controlling corrosive, abrasive, or viscous media like acids, slurries, and sludges, where preventing leaks and contamination is critical for safe and efficient operations.

You see, the magic of these valves isn't just what they do, but how they do it. Their design opens up a world of possibilities across various sectors. To really understand their value, we need to look closer at why they are the top choice for such demanding environments. Let's explore the core features that make them so versatile.

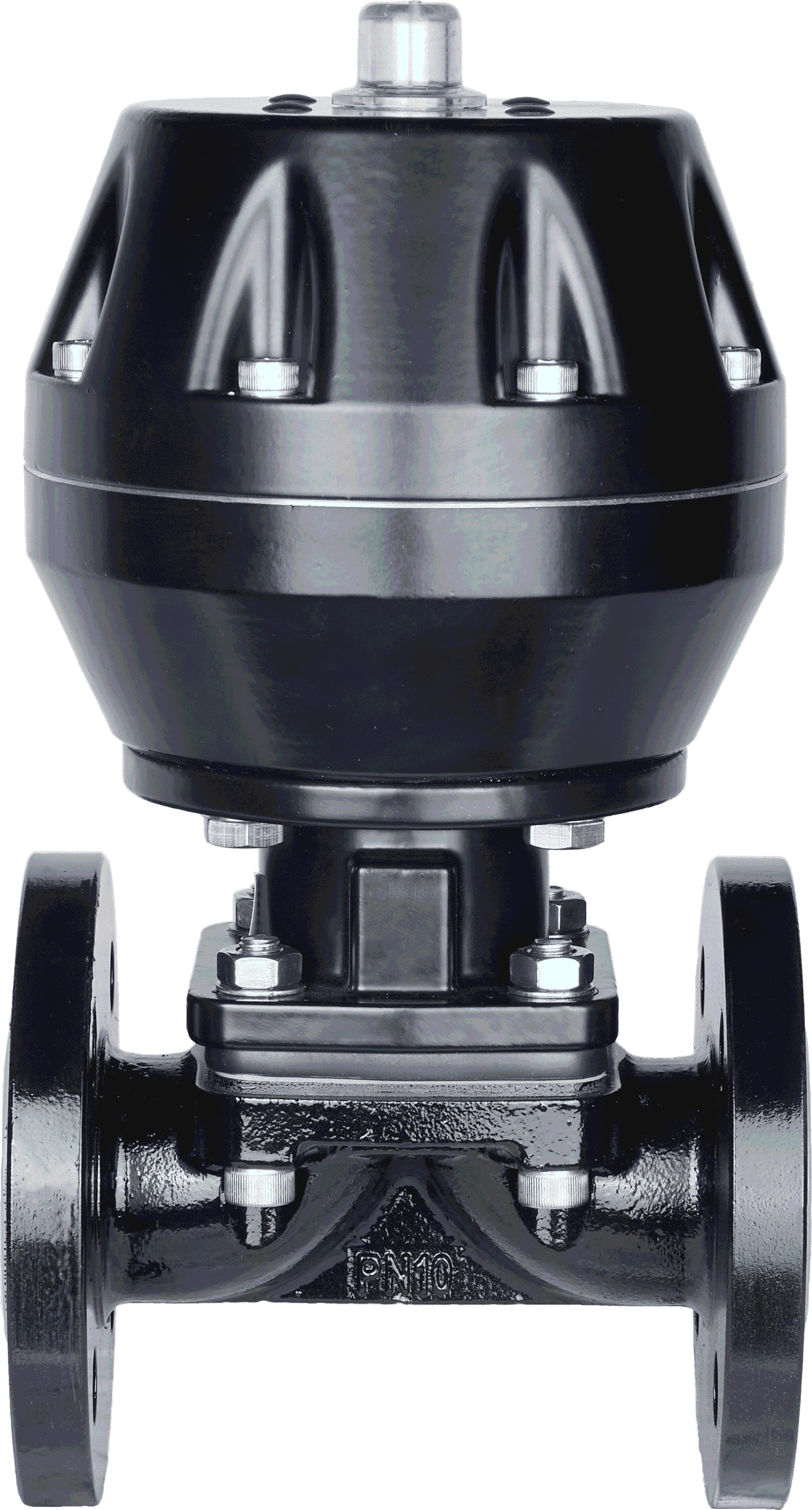

How Does a Pneumatic Diaphragm Valve's Design Prevent Leaks?

Worried about stem leaks[^5] from your valves? These leaks risk safety and require constant maintenance. Pneumatic diaphragm valves[^1] have a unique design that completely isolates the stem, eliminating this problem.

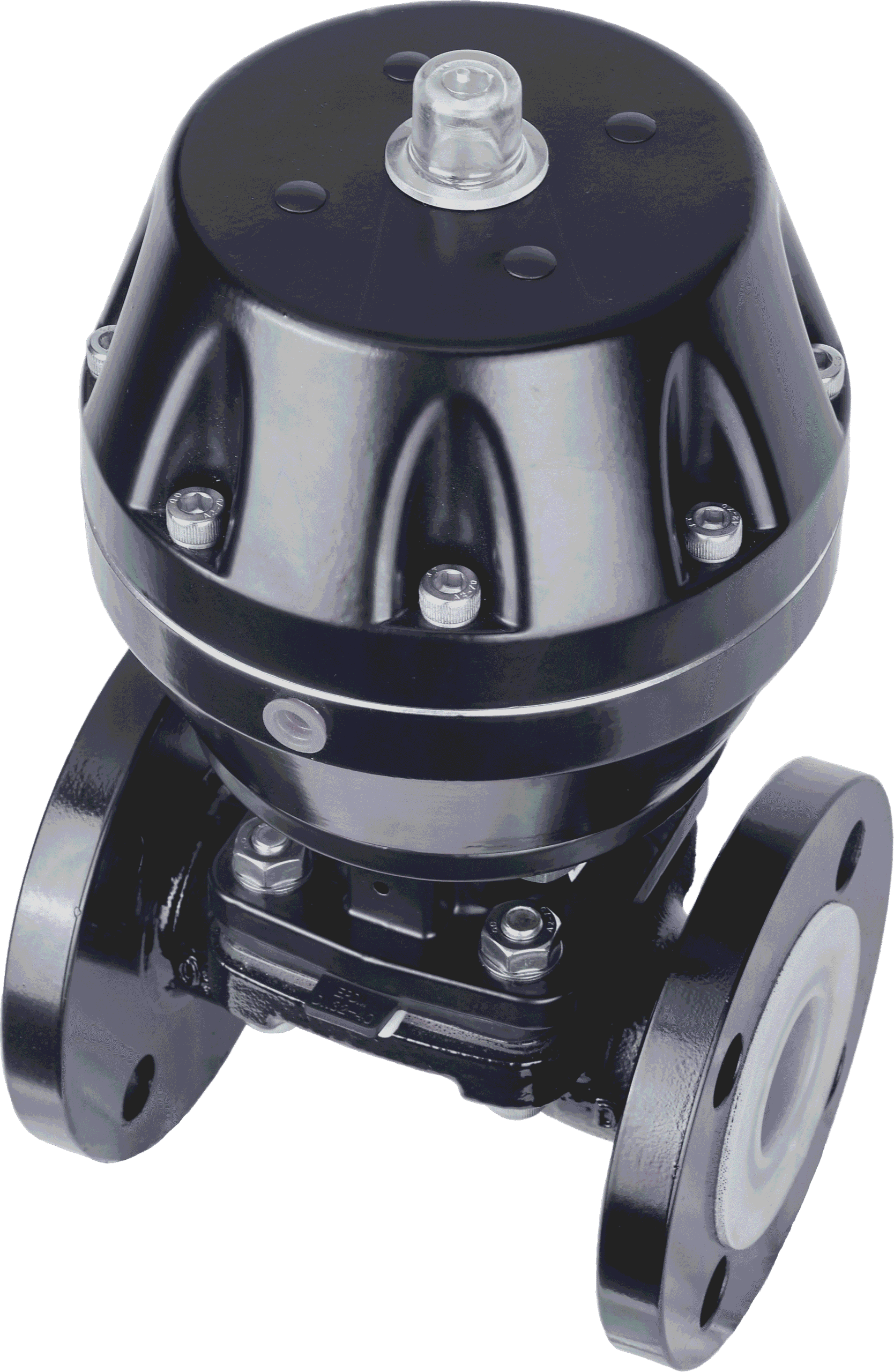

A pneumatic diaphragm valve uses a flexible diaphragm[^6] to separate the valve's inner body from its operating mechanism. This diaphragm acts as both the flow control element and the seal. Because the stem doesn't touch the media, there's no need for traditional packing, preventing media leakage.

I've been in this business for years, and the most common failure point I see in other valves is the stem packing. With a pneumatic diaphragm valve, that problem is gone. The diaphragm is a clever piece of engineering. It's a flexible barrier that is pressed down by a compressor to stop the flow. This single part does two jobs: it stops the media and it seals the valve bonnet. This means the actuator, stem, and other moving parts are never exposed to the corrosive or abrasive fluid inside the pipe. This isolation is the valve's biggest strength. We can classify them based on their default state: Normally Closed (air pressure opens it), Normally Open (air pressure closes it), or Reciprocating (air pressure moves it in both directions). This simple, effective design is what makes them so reliable.

Design Comparison: Diaphragm vs. Traditional Valves

| Feature | Pneumatic Diaphragm Valve | Traditional Gate/Globe Valve |

|---|---|---|

| Sealing Mechanism | Flexible diaphragm isolates media | Stem packing around a moving stem |

| Leakage Path | No external leak path from media | Potential leak path along the stem |

| Media Contact | Only body, lining, and diaphragm | Body, disc, seat, and stem |

| Maintenance | Simple diaphragm replacement | Complex packing and seal replacement |

Which Industries Benefit Most from Pneumatic Diaphragm Valves?

Do your operations involve abrasive slurries or harsh chemicals? The wrong valve quickly fails, causing costly shutdowns. Pneumatic diaphragm valves[^1] are engineered specifically for these demanding industrial applications.

Key industries include chemical processing, power plants (for water treatment and ash handling), and wastewater treatment[^4]. They are also used in mining for ore slurries and even in semiconductor manufacturing. Their ability to handle viscous, abrasive, and corrosive media[^7] makes them incredibly versatile and reliable.

When a client comes to me with a fluid that's "difficult," I almost always recommend a diaphragm valve. In the chemical industry, they are workhorses for handling acids, alkalis, and solvents. Our plastic linings like PTFE provide superior chemical resistance. For power plants, especially in flue gas desulfurization (FGD) systems, these valves handle abrasive limestone and gypsum slurries without clogging. Their simple flow path is a huge advantage here. And in wastewater treatment[^4], they are perfect for dosing chemicals or managing sludge lines. The rubber linings, like EPDM, offer great performance and a tight seal, even with solids in the flow. The key is matching the valve's body and lining material to the specific application, which is where our expertise as a manufacturer comes in. We focus on cost-effective cast iron and ductile iron bodies, which are perfect for these large-scale industrial uses.

Key Industrial Applications

| Industry | Common Media | Key Benefit |

|---|---|---|

| Chemical | Acids, Alkalis, Solvents | Excellent corrosion resistance and leak-proof design. |

| Power Plant | Ash Slurry, Limestone Slurry | High abrasion resistance and non-clogging flow path. |

| Wastewater | Sludge, Chemical Dosing | Reliable shut-off with solids and chemical compatibility. |

| Mining | Ore Slurries, Reagents | Handles high-solid content and abrasive materials[^8]. |

When Should You Not Use a Pneumatic Diaphragm Valve?

Think a diaphragm valve is a one-size-fits-all solution? Using it in the wrong conditions leads to failure. Knowing its limitations helps you avoid costly mistakes and choose wisely.

Generally, avoid standard diaphragm valves for high-temperature or high-pressure applications[^9]. The flexible diaphragm[^6] materials have temperature and pressure limits. They are also not ideal for fast-cycling operations or when a very short valve body length is required. Always check the specific operational parameters.

I believe in being honest with my clients. A pneumatic diaphragm valve is a fantastic tool, but it's not the right tool for every single job. The main limitations come from the diaphragm itself. Since it's made of a flexible material like rubber or plastic, it has limits. High temperatures can cause the material to degrade, and high pressures can exceed its structural limits. Think of it like a tire—it works perfectly within its pressure rating, but you wouldn't use a car tire on a jumbo jet. They are also not designed for rapid, constant opening and closing, as this can cause premature wear on the diaphragm. For applications requiring high-pressure shut-off or extreme temperatures, other valve types are usually a better fit. Being aware of these boundaries is just as important as knowing the benefits.

Application Suitability Guide

| Condition | Recommended for Diaphragm Valves? | Reason |

|---|---|---|

| Abrasive Slurries | Yes | Smooth flow path, durable linings. |

| Corrosive Chemicals | Yes | Isolated mechanism, resistant linings. |

| High Temperature (>150°C) | No (for standard) | Diaphragm material may degrade. |

| High Pressure (>10 bar) | No (for standard) | Diaphragm may fail to seal or rupture. |

| Strict Sanitary Needs | Yes (with right materials) | No contamination from mechanism. |

Conclusion

Pneumatic diaphragm valves[^1] are a top choice for controlling difficult media in many industries. Their isolated design ensures reliability and prevents leaks, making them a powerful and cost-effective solution.

[^1]: Explore the advantages of pneumatic diaphragm valves for handling corrosive and abrasive media in various industries. [^2]: Learn how pneumatic diaphragm valves enhance safety and efficiency in chemical processing operations. [^3]: Discover the importance of these valves in optimizing processes within power generation facilities. [^4]: Find out how these valves ensure reliable operation in wastewater treatment applications. [^5]: Discover effective strategies to eliminate stem leaks and enhance valve reliability. [^6]: Learn about the critical role of the flexible diaphragm in preventing leaks and ensuring valve performance. [^7]: Understand the unique design features that allow these valves to manage corrosive substances effectively. [^8]: Explore the difficulties faced when using traditional valves with abrasive materials and how diaphragm valves solve them. [^9]: Learn about the risks associated with using diaphragm valves in high-pressure scenarios.