Valve specifications and categories should meet the requirements of the pipeline design documents

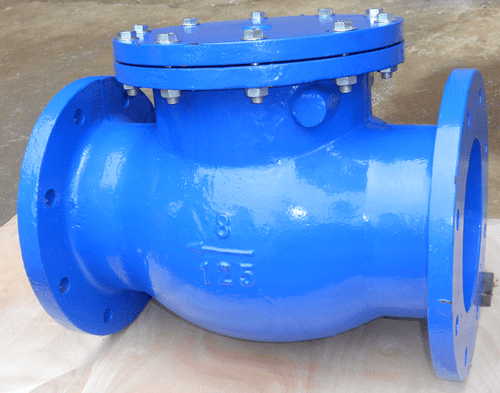

1 Valve working pressure is required to be greater than or equal to the working pressure of the pipeline. Under the premise of not affecting the price, the working pressure that the valve can withstand should be greater than the actual working pressure of the pipeline; any side of the valve should be able to withstand 1.1 times the working pressure of the valve when the valve is closed Value without leakage; when the valve is open, the valve body should be able to withstand 1.5 times the valve working pressure.

2 The valve manufacturing standard should indicate the number based on it. If it is a corporate standard, the purchase contract should be accompanied by corporate documents

Choose the material of the valve

1 Valve material, the material of the valve body should be mainly ductile iron, and the grade and actual physical and chemical testing data of the casting should be indicated.

2 Stem material, strive for stainless steel stem (2Cr13), large diameter valves should also be stainless steel embedded stems.

3 The nut material is made of cast aluminum brass or cast aluminum bronze, and the hardness and strength are greater than the valve stem

4 The material of the valve stem bushing shall have a hardness and strength not greater than that of the valve stem, and will not form electrochemical corrosion with the valve stem and valve body under water immersion conditions.

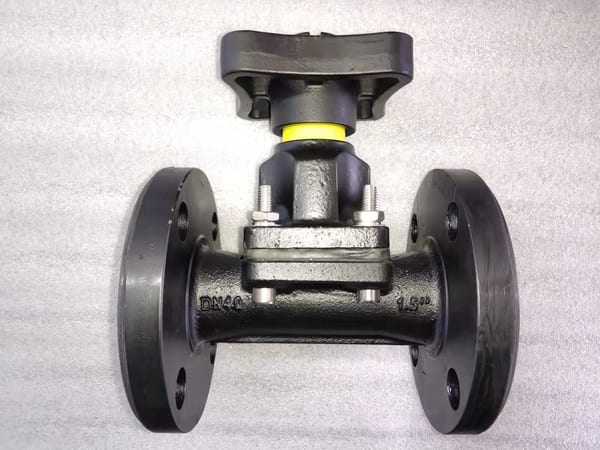

Valve shaft packing

①As the valves in the pipe network are usually opened and closed infrequently, the packing is required to be inactive for several years, and the packing does not age, so as to maintain the sealing effect for a long time;

②The valve shaft packing should also have a good sealing effect when it is subjected to frequent opening and closing;

③In view of the above requirements, the valve shaft packing shall not be replaced for life or for many years;

Variable speed transmission box

1. The material of the box body and the internal and external anti-corrosion requirements are consistent with the principle of the valve body.

2. The box body should have sealing measures

3. For the opening and closing limit device on the box body, the adjusting nut should be inside the box body.

4. The design of the transmission structure is reasonable. It can only drive the valve shaft to rotate when opening and closing, and does not make it move up and down, and the transmission parts bite properly and do not cause separation and slippage when opening and closing with load.

5. The seal of the variable speed transmission box and the valve shaft cannot be connected into a leak-free whole.

6. There is no debris in the box, and the gear bite part should be protected by grease.

Valve operating mechanism

1 The opening and closing direction of the valve should always be closed clockwise.

2 As the valves in the pipe network are often opened and closed manually, the number of opening and closing revolutions should not be too much, even large-diameter valves should also be within 200-600 revolutions.

3 In order to facilitate the opening and closing operation of one person, the maximum opening and closing torque should be 240nm under the condition of pipeline pressure

4 The opening and closing end of the valve should be a square captop, with standardized dimensions, and face the ground so that people can directly operate it from the ground. Valves with handwheel are not suitable for underground pipe networks

5 Display panel of valve opening and closing degree

① The scale line of the valve opening and closing degree should be cast on the gearbox cover or on the shell of the display panel after changing the direction.

②The material of the indicator disc needle can be made of stainless steel plate under good management, otherwise it is painted steel plate, do not use aluminum skin;

③The indicator disc needle is eye-catching and fixed firmly. Once the opening and closing adjustment is accurate, it should be locked with rivets.

6 If the valve is buried deeply, and the distance between the operating mechanism and the display panel is ≥15m from the ground, an extension rod facility should be provided, and it should be firmly fixed so that people can observe and operate it from the ground. In other words, the opening and closing operations of valves in the pipe network are not suitable for downhole operations.

Valve performance testing

The valve should undergo the following inspections before leaving the factory:

① When the valve is open, the valve body should withstand a pressure test that is 1.5 times the working pressure of the valve;

②When the valve is closed, both sides bear 1.1 times the valve working pressure value, and there is no leakage; however, the leakage value of the metal-sealed butterfly valve is not greater than the relevant requirements.

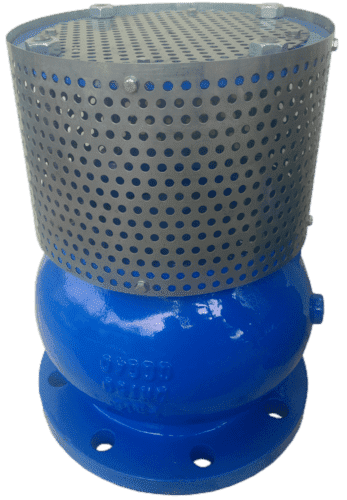

Internal and external corrosion protection of the valve

1 The inside and outside of the valve body (including the variable-speed transmission box) should be shot blasted to clean the sand and rust, and strive to electrostatically spray the powdery non-toxic epoxy resin with a thickness of more than 200um. When it is difficult to electrostatic spray non-toxic epoxy resin for extra-large valves, similar non-toxic epoxy paint should also be brushed or sprayed.

2 The inside of the valve body and all parts of the valve plate require comprehensive anti-corrosion. On the one hand, it will not corrode when immersed in water, and no electrochemical corrosion will occur between the two metals; on the other hand, the smooth surface will reduce the resistance to water。