Valve installation-Technical requirements

In the flow control system, valve is a device used to control the direction, pressure, and flow of the fluid. During the construction process, the quality of valve installation directly affects the normal operation in the future, so the construction unit and production unit must pay great attention to it.

Now let we talk about technical requirements for valve installation

- Directionality: generally, there is a mark on the valve body of the valve, and the direction indicated by the arrow is the direction in which the gas flows forward. Special attention must be paid to not install it backwards. Because there are various valves that require gas to flow in one direction, such as safety valves, pressure reducing valves, check valves, throttle valves, etc., in order to facilitate opening and maintenance of stop valves, gas is also required to pass through the valve seat from bottom to top, but when gate valve is installed, it is not restricted by the direction of circulation.

2. Installation location. Long-term operation and maintenance of the valve should be considered, and the operation and maintenance should be as convenient as possible. At the same time, attention should be paid to the beautiful appearance of the assembly. The valve handle direction can be vertical upwards, can also be inclined to a certain angle or placed horizontally, but the handwheel should not be downward to avoid face-up operation; the handwheel of the floor valve should be chest-high to facilitate opening and closing; open-stem gate valves cannot be used It is underground to prevent the valve stem from being corroded.

Some valves have special requirements for the installation position. For example, the pressure reducing valve must be installed upright on a horizontal pipe without tilting. The lift check valve requires the valve disc to be vertical; the swing check valve requires the pin shaft to be horizontal. In short, the installation position of the valve must be determined according to the principle of the valve, otherwise the valve will not work effectively, or even not work.

3.When installing the threaded valve, the valve company should ensure that the thread is intact and undamaged; use a wrench when a wrench can be used, and do not use a pipe wrench to avoid damage to the appearance of the valve body.

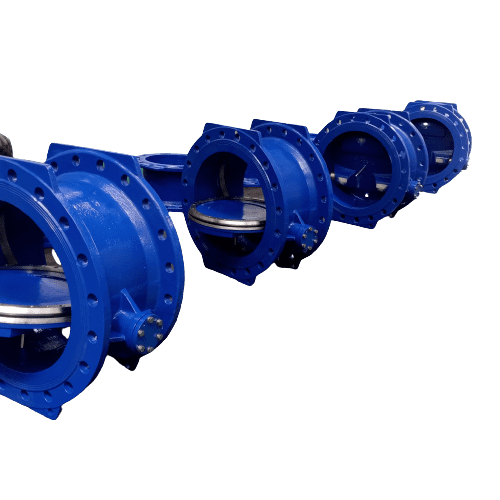

4.The installation of flanged valves must ensure that the sections of the two flanges are parallel to each other and on the same axis. The bolts should be tightened in a crisscross pattern to make the end face of the valve evenly stressed.

- Valves connected by flanges and threads should be installed in the closed state. When the butt welding valve is connected with the pipeline, the bottom of the weld should be welded with argon welding to ensure the internal cleanliness. During welding, the valve should not be closed to prevent thermal deformation.

- Under normal circumstances, the valve is directly connected to the bellows expansion joint, so according to the size of the valve and the bellows expansion joint as well as the flange and gasket, the pipes on both sides should be cut off and the installation position should be reserved.

7. When the valve is hoisted, the rope should not be tied to the handwheel or the valve stem to prevent damage. It should be lifted and put gently, and no collision. When placed on the buttress, it should be stabilized and leveled according to the required elevation. There must be a firm buttress or bracket under the valve to hold the valve, and the valve is not allowed to hang in the air to generate stress.