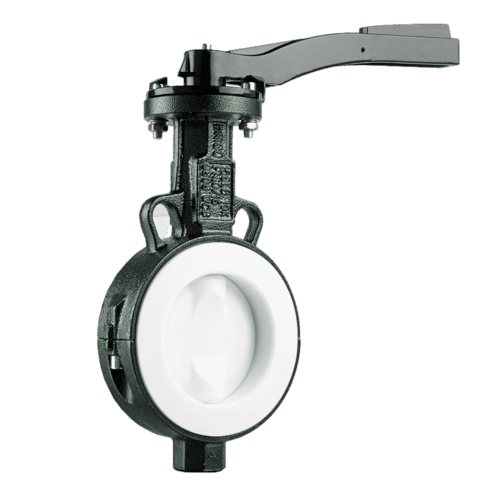

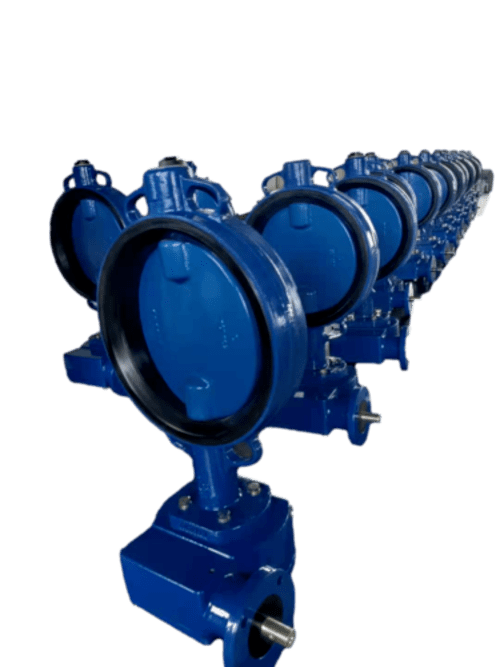

The butterfly disc of the wafer butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical passage of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, and the rotation angle is between 0°-90°, which can play a role in flow adjustment. When the butterfly plate rotates to 90°, the valve reaches the maximum Opening. The wafer butterfly valve is simple in structure, small in size and light in weight, and consists of only a few parts. Moreover, it can be opened and closed quickly by rotating 90°, and the operation is simple. At the same time, the valve has good fluid control characteristics.

Precautions for the installation of wafer butterfly valve

1. Before installation, the sealing surface of the valve and the dirt and impurities in the pipeline must be cleaned up, and there should be no impurities.

2. When installing the valve, the flange inner port on the pipeline must be aligned with the ear hole of the wafer butterfly valve. The flange piece and the rubber sealing ring of the butterfly valve are tightly pressed and fitted, and no sealing gasket is used.

3. Before the valve is fixed, the butterfly plate should be tested for several times to make sure that the butterfly plate is not blocked during the switching process, and then the nut can be completely tightened and fixed. Note: This test is very important for the jamming of clip-on butterfly valves. If there is no test during installation, jamming after installation will cause the butterfly valve to fail to open or close completely, resulting in a large amount of leakage. If it is a butterfly valve with an electric or pneumatic actuator, the actuator will twist the valve stem and deform.

4. The sequence of welding flange and installing butterfly valve must not be disordered, and the butterfly valve must not be installed first and then welding flange, this will burn the butterfly valve rubber sealing ring.

5. For the wafer butterfly valve installed with electric or pneumatic actuators, when replacing the lower part, it is necessary to assemble the closed position to the closed position and the open position to the open position. After the whole machine is adjusted and calibrated, install it on the pipeline.