Seal elements are frequently used sealing parts for machinery and equipment, and are materials that play a sealing role. From this definition, it is not difficult for us to know how important the seal element is, so how to install the seal element is worthy of our attention. The correct installation can ensure the sealing performance and make the equipment run smoothly, otherwise it will damage the sealing seal element. Next, let’s take a closer look at what should be done.

The correct installation of the seal element should be carried out when the flange connection structure or the threaded connection structure, the static sealing surface and the seal element are undoubtedly checked, and the other valve parts are intact.

01 Before assembling the seal element, coat the sealing surface, seal element, thread and rotating parts of bolts and nuts with a layer of graphite powder or a lubricant blended with graphite powder and oil (or water). The seal element and graphite should be kept clean.

02 The seal element should be installed on the sealing surface to be centered and correct, not to be slanted, and not to extend into the valve cavity or rest on the shoulder.

03 Only one piece of seal element is allowed to install, and two or more pieces are not allowed to be installed between the sealing surfaces to eliminate the insufficient gap between the two sealing surfaces.

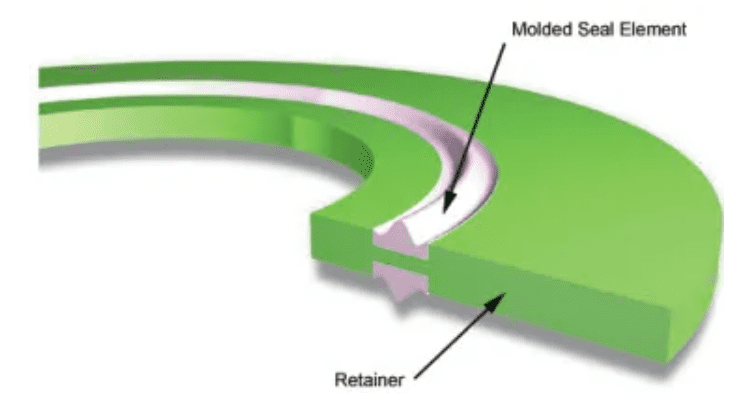

04 The oval seal element should be sealed so that the inner and outer rings of the seal element are in contact, and the two ends of the seal element should not be in contact with the bottom of the groove.

05In the installation of O-rings, except that the ring and groove should meet the design requirements, the amount of compression should be appropriate. Under the premise of ensuring the seal, the smaller the compression deformation rate, the better, which can extend the life of the O-ring.

06 The valve should be in the open position before the seal element is placed on the cover, so as not to affect the installation and damage the valve parts. When closing the cover, align the position and do not contact the seal element by pushing or pulling, so as to avoid displacement and scratches of the seal element.

07 The installation of bolted or threaded seal elements should be such that the seal elements are in a horizontal position (the seal element cover for threaded connections, do not use pipe wrenches if there is a wrench position).

08 Before the seal element is compressed, the pressure, temperature, properties of the medium, and seal element material characteristics should be clearly understood, and the pre-tightening force should be determined. The pre-tightening force should be as small as possible under the condition that the pressure test does not leak

09 After the seal element is tightened, it should be ensured that there is a pre-tightening gap for the connecting piece, so that there is room for pre-tightening when the seal element leaks.

10 When working at high temperatures, the bolts will experience high temperature creep, stress relaxation, and increased deformation, leading to leakage at the seal element and requiring thermal tightening; on the contrary, under low temperature conditions, the bolts will shrink and require cold loosening.

11 When a liquid seal element is used for the sealing surface, the sealing surface should be cleaned or surface treated. The flat sealing surface should be consistent after grinding, and the adhesive should be evenly coated, and air should be removed as much as possible. The adhesive layer is generally 0.1-0.2mm.

12 When using PTFE film raw tape for thread sealing, the starting point of the film should be stretched thin and glued to the thread surface, and then the excess tape at the starting point should be removed to make the film sticking to the thread into a wedge shape.

Through the above introduction, everyone knows how the seal element is installed. The installation is not complicated, but there are many details that need to be paid attention to. After the details are handled, the installation can be smooth. The correct installation is related to the sealing and operation of the equipment, so the installation operator should keep the above items in mind, and carefully check during the installation work.