Why the butterfly valve is called the butterfly valve? As the name implies, its key components are like a butterfly facing the wind and turning freely. The disc of the butterfly valve is a disc, which rotates around an axis in the valve seat. The size of the rotation angle is the opening and closing degree of the valve.

The structure of the butterfly valve

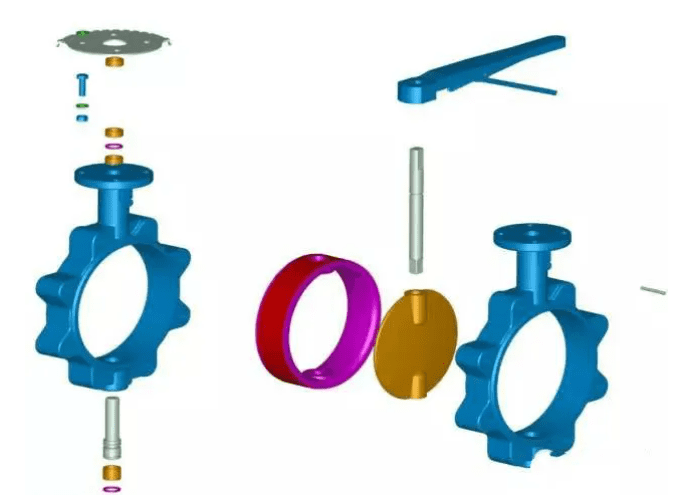

Butterfly valve is mainly composed of valve body, valve shaft, bearing, sealing device, operating mechanism and accessory parts

The structure of the butterfly valve:

- One piece shat and with pin

- One piece shat and without pin

- Two piece shat and with pin

- Two piece shat and without pin

- One piece shat and without pin Viton lined

- One piece shat and with pin EPDM seat

The working principle of butterfly valve

The butterfly valve is a valve that opens and closes according to the rotation of the valve stem while driving the disc plate to rotate. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, mainly by rotating the disc plate 90° for flow control. , When the disc reaches 90°, the valve is in a fully open state, and the angle of the disc can be changed to adjust the medium flow. It is generally installed in the diameter direction of the pipe. The butterfly valve and the valve stem have no locking ability. In order to effectively adjust the flow, a worm gear reducer is required. The butterfly valve with a worm gear reducer not only makes the butterfly valve self-locking, but also changes the operating performance of the butterfly valve and adjusts the medium flow more accurately.

1. The butterfly valve has a small flow resistance when it is fully opened. When the opening is between about 15° and 70°, it can carry out sensitive flow control. Therefore, the application of butterfly valves is very common in the field of large-diameter adjustment. Since the movement of the butterfly plate of the butterfly valve is wiping, most butterfly valves can be used for media with suspended solid particles. Depending on the strength of the seal, it can also be used for powder and granular media.

2. The butterfly valve is suitable for flow adjustment. Because the pressure loss of the butterfly valve in the pipe is relatively large, about three times that of the gate valve, when selecting the butterfly valve, the influence of the pressure loss of the pipeline system should be fully considered, and the strength of the butterfly plate withstand the pressure of the pipeline medium when it is closed should also be considered. . In addition, it is necessary to consider the limitation of the working temperature that the elastic valve seat material can withstand at high temperatures.

3. The structure length and overall height of the butterfly valve are small, the opening and closing speed is faster, and it has good fluid control characteristics. The structure principle of butterfly valve is most suitable for making large-diameter valves. When the butterfly valve is required to control flow, the most important thing is to correctly select the specification and type of the butterfly valve so that it can work properly and effectively.

Classification of butterfly valve

1 concentric butterfly valve

The structural feature of this kind of butterfly valve is that the Axes of the valve stem, the center of the butterfly plate and the center of the body are in the same position.

The structure is simple and the manufacturing is convenient. Common rubber-lined butterfly valves belong to this category. The disadvantage is that the butterfly plate and the valve seat are always in a state of squeezing and scratching, with a large resistance distance and fast wear. In order to overcome squeezing, scratching, and to ensure sealing performance, the valve seat is basically made of rubber or PTFE and other elastic materials, but it is also subject to temperature restrictions in use. This is why traditionally people think that butterfly valves are not resistant to high temperatures. reason.

Single eccentric butterfly valve

The single eccentric butterfly valve solves the problem of the extrusion of the butterfly plate and the valve seat of the concentric butterfly valve, resulting in a single eccentric butterfly valve. Its structural feature is that the stem axis deviates from the center of the butterfly plate, so that the upper and lower ends of the butterfly plate no longer become rotating The axial center is dispersed, and the excessive extrusion between the upper and lower ends of the butterfly plate and the valve seat is reduced.

However, because the single eccentric structure does not disappear from the scratching phenomenon of the butterfly plate and the valve seat during the entire opening and closing process of the valve, and the scope of application is similar to that of the concentric butterfly valve, it is not used much.

Single eccentric butterfly valve structure features:

1. The center of rotation of the disc plate (that is, the center of the valve shaft) is located on the center line of the valve body, and an A-size offset is formed on the sealing section of the valve plate. The single eccentric butterfly valve is that the rotation center of the disc plate is on the center line of the valve body, and the valve plate deviates a distance from the sealing surface, which is suitable for soft sealing.

2. When the valve is closed, the valve seat and the sealing surface of the valve plate are in a relatively interference contact state. To achieve the seal, it is mainly by pressing the sealing ring to expand in the peripheral direction to produce the sealing specific pressure and pipeline pressure against the valve plate. It can only be sealed in one direction because of the strong force.

3. When the valve is opened, the contact side of the valve plate and the valve seat is separated from the valve seat, and the other side is always two-point contact along the axial direction of the half circumference. Repeated opening and closing of the sealing ring is easy to be damaged, which affects the sealing performance, and more It is impossible to achieve a metal seal.

The double eccentric butterfly valve

The double eccentric butterfly valve is further improved on the basis of the single eccentric butterfly valve, which is currently the most widely used double eccentric butterfly valve.

Double eccentric butterfly valve structure features:

The center of rotation of the valve plate (that is, the center of the valve shaft) forms an offset of dimension A on the sealing section of the valve plate, and forms an offset of dimension B with the center of the valve body.

Its structural feature is that the axis of the valve stem deviates from the center of the butterfly plate and the center of the body. The double eccentric effect enables the butterfly plate to be released from the valve seat immediately after the valve is opened, which greatly eliminates unnecessary excessive extrusion and scratching of the butterfly plate and the valve seat, reduces the opening resistance, reduces wear and improves The life of the valve seat is improved. The scraping is greatly reduced, and at the same time, the double eccentric butterfly valve can also use a metal seat, which improves the application of the butterfly valve in the high temperature field.

Double eccentric butterfly valve sealing principle.

Because its sealing principle is a positional sealing structure, that is, the sealing surface of the butterfly plate and the valve seat is in line contact, and the elastic deformation caused by the butterfly plate squeezing the valve seat produces a sealing effect, so the closing position is very demanding, especially for the metal valve seat. , Low pressure bearing capacity, which is why traditionally people think that butterfly valves are not resistant to high pressure and have large leakage.

The triple eccentric butterfly valve

The triple eccentric butterfly valve must be resistant to high temperature, and must use a metal seal. However when it must have zero leakage if the leakage is large, and must use a soft seal, but it is not resistant to high temperatures.

Structural features of triple eccentric butterfly valve:

The center of rotation of the valve plate (ie the center of the valve shaft) forms an offset A on the sealing section of the valve plate and an offset b from the center of the valve body; the centerline of the valve body sealing surface and the centerline of the valve seat (ie the centerline of the valve body) An angular offset of β is formed.

In order to overcome the contradiction of the double eccentric butterfly valve, the butterfly valve was eccentric for the third time. Its structural feature is that while the double eccentric valve stem axis position is eccentric, the conical axis of the butterfly plate sealing surface is skewed to the cylinder axis of the body, that is to say, after the third eccentricity, the sealing section of the butterfly plate is not Furthermore, it is a true circle, but an ellipse, and the shape of the sealing surface is therefore asymmetrical. One side is inclined to the center line of the body, and the other side is parallel to the center line of the body.

The biggest feature of the triple eccentric butterfly valve is that the sealing structure is fundamentally changed. It is no longer a position seal, but a torsion seal, that is, it does not rely on the elastic deformation of the valve seat, but completely relies on the contact surface pressure of the valve seat to achieve the sealing effect.