Struggling with clogged valves from thick slurries? This constant downtime costs you money and time. Our straight-through diaphragm valves[^1] valves offer a simple, effective solution for uninterrupted flow.

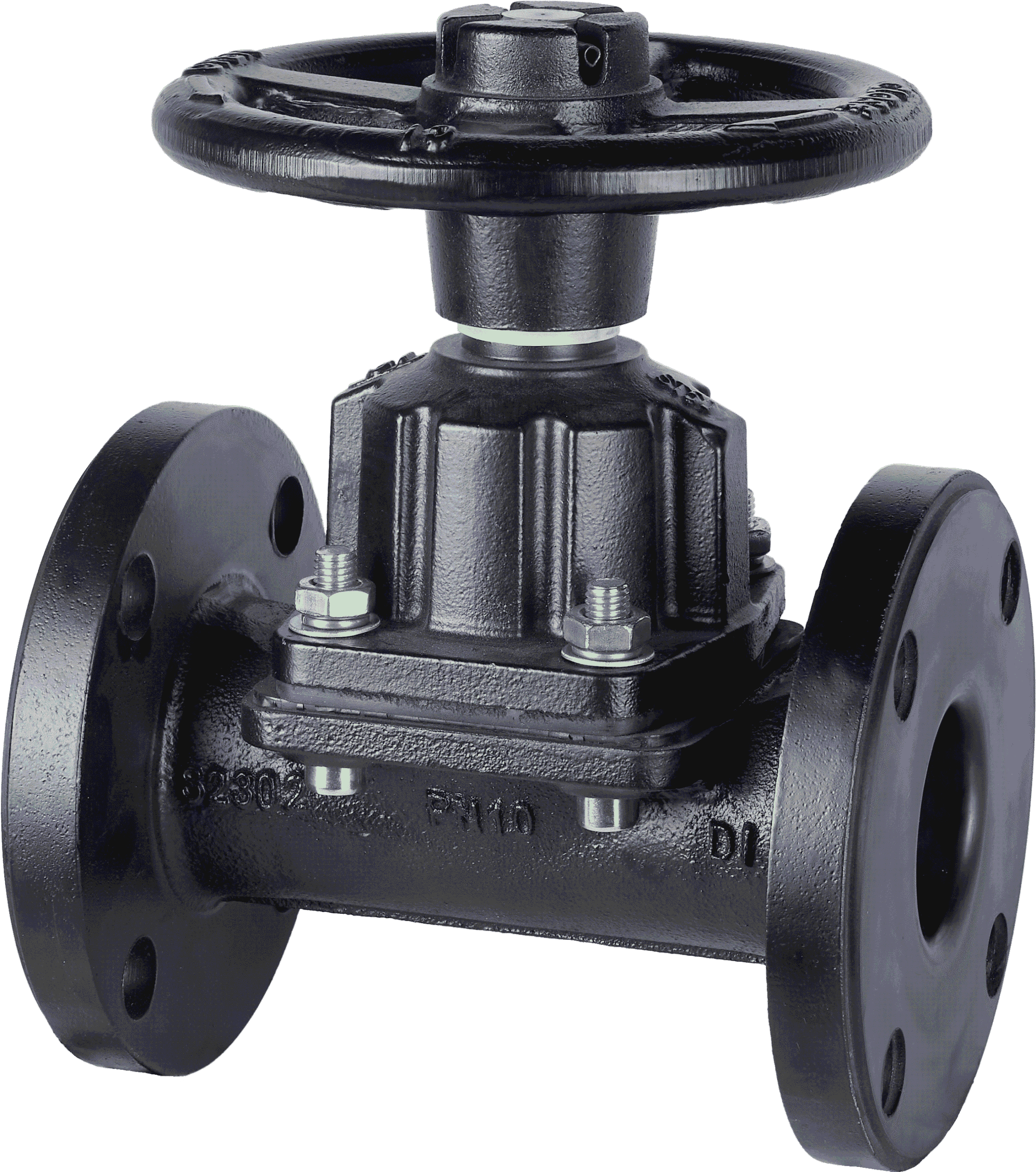

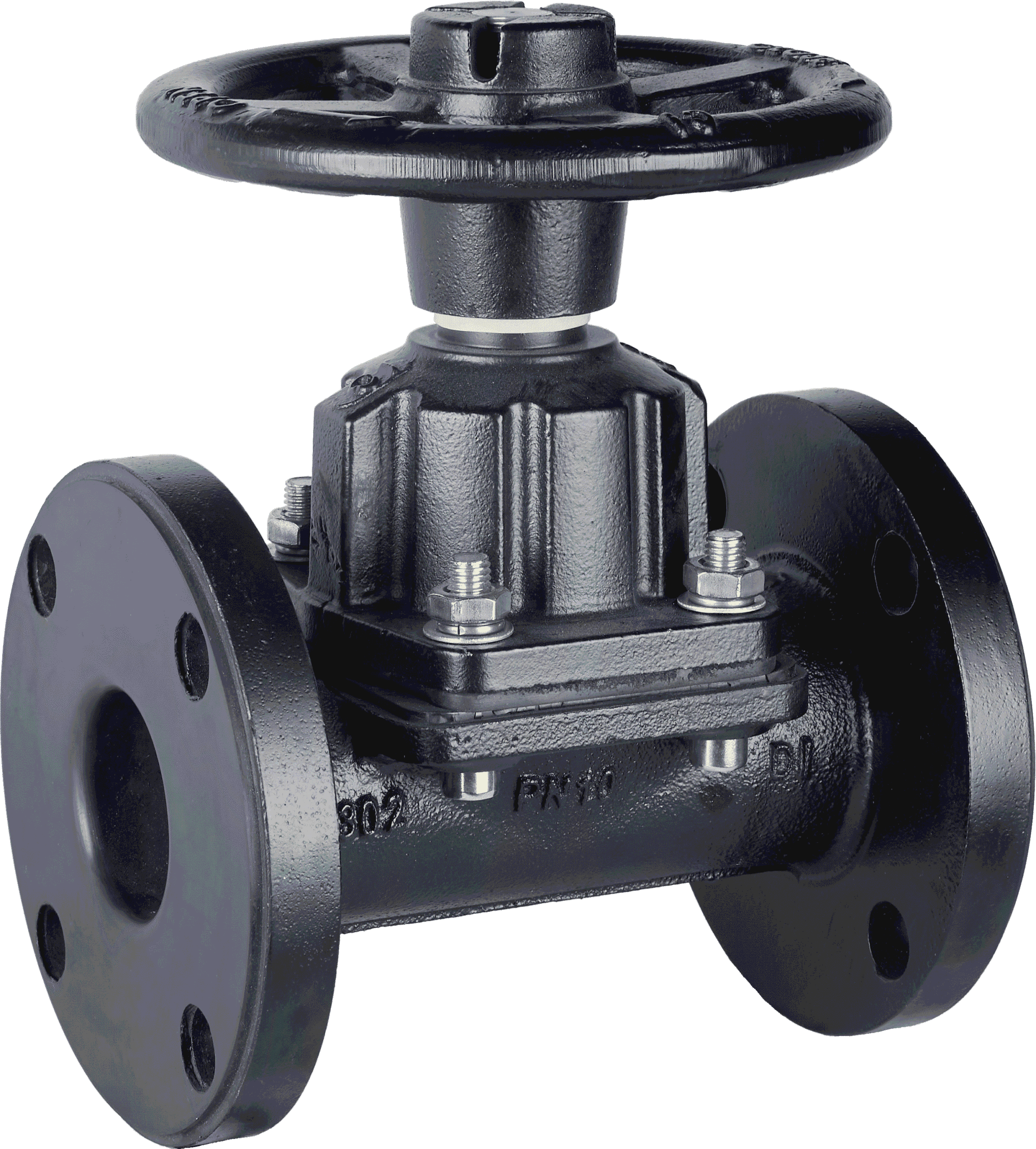

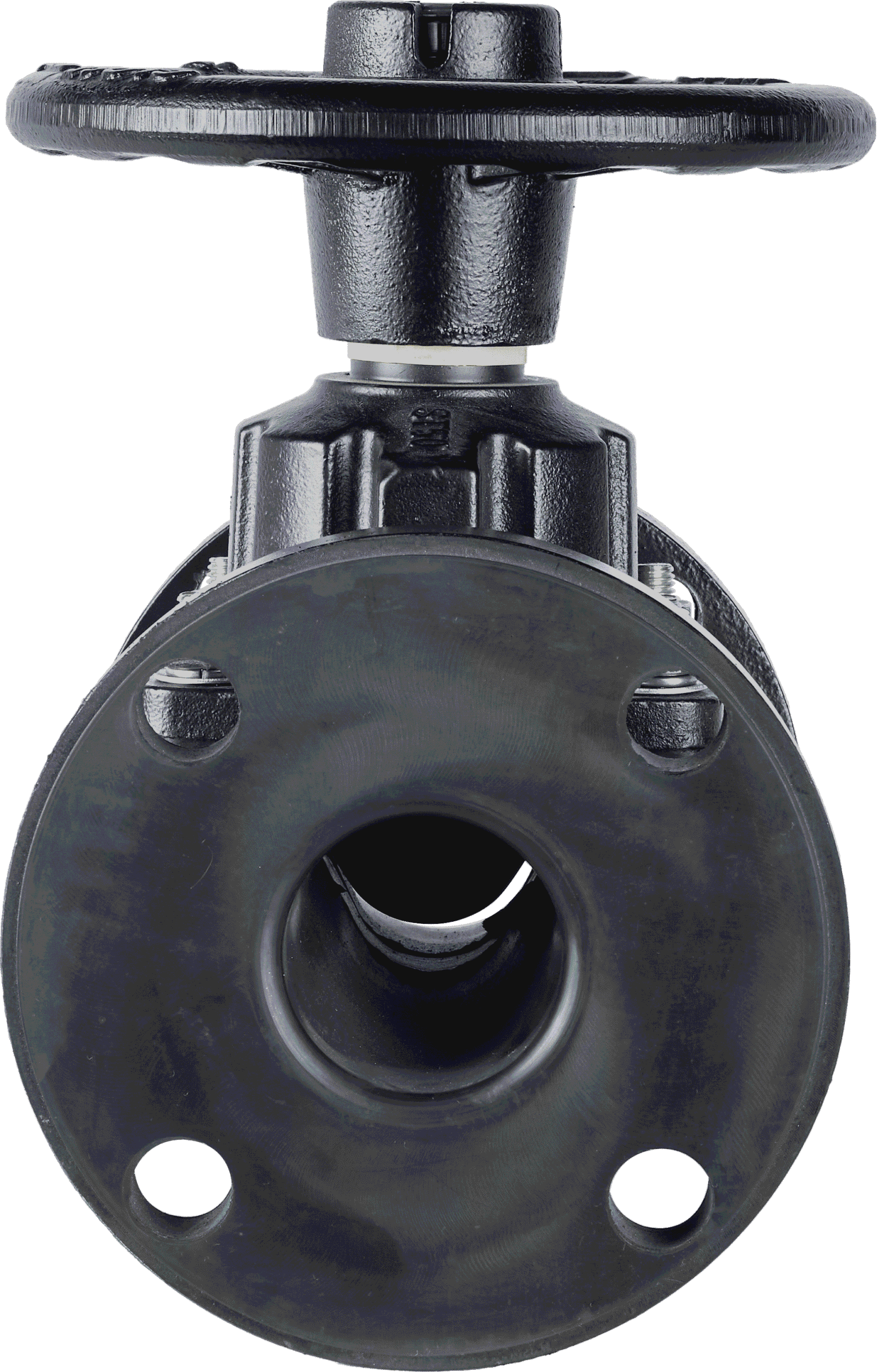

Straight-through diaphragm[^2] valves, also known as full-bore valves[^3], use a flat-bottom body and a flexible diaphragm[^2]. This design creates a completely unobstructed path, allowing viscous fluids, slurries, and sludges to flow smoothly without clogging, ensuring reliable performance in demanding industrial applications.

That's the quick answer, but the real value is in the details of the design and how it works in specific situations. I've worked with these valves for years, and I've seen firsthand how they solve major problems for our clients. Let's break down exactly what makes them so special.

What Makes the Straight-Through Design So Effective for Slurries?

Are your current valves failing under the pressure of abrasive slurries? This leads to frequent maintenance and costly replacements. The unique straight-through design is built to handle these challenges easily.

The effectiveness comes from its full-bore, flat-bottom body. Unlike weir-type valves[^4], there are no obstructions or changes in direction for the fluid. This straight path minimizes turbulence and prevents solid particles in slurries from settling and causing blockages, ensuring a smooth, continuous flow.

When I talk to clients dealing with slurries or sludges, their biggest complaint is always clogging. The straight-through, or full-bore, diaphragm[^2] valve directly solves this problem. Let's look at the mechanics.

The Importance of an Unobstructed Flow Path

The key is in the name: "straight-through". The inside of the valve body is a simple, straight tube when the valve is open. There are no bumps, dips, or raised sections to get in the way. This is very different from a weir-type valve, which has a raised "weir" in the middle. For fluids with high solids content, like in mining or wastewater treatment, any obstruction is a potential point for material to build up and create a blockage. The straight-through design eliminates this risk. It also means there is very little pressure drop as the fluid passes through, which improves system efficiency. Plus, this design allows for bi-directional flow, meaning the fluid can travel in either direction, adding flexibility to your piping design.

How the Diaphragm Closes

In this design, the diaphragm[^2] pushes down and seals against the flat bottom of the valve body to stop the flow. This requires the diaphragm[^2] to travel further and be more flexible compared to a weir-type. While this might mean the diaphragm[^2] wears a bit faster in high-cycle applications, it's a necessary trade-off for the superior handling of viscous and solid-laden fluids. It's the only way to get that completely clear passage that prevents clogging.

| Feature | Straight-Through Diaphragm Valve | Weir-Type Diaphragm Valve |

|---|---|---|

| Flow Path | Straight, unobstructed (Full Bore) | Obstructed by a raised weir |

| Slurry Handling | Excellent, minimizes clogging | Prone to clogging with solids |

| Flow Control | Good for on/off applications | Better for fine throttling |

| Diaphragm Travel | Long travel | Short travel |

| Flow Direction | Bi-directional | Uni-directional |

Where Are Rubber-Lined Straight-Through Valves Most Commonly Used?

Worried about finding a valve that can survive your corrosive or abrasive environment? The wrong choice can lead to leaks and system failure. Our rubber-lined valves[^5] are a proven solution.

Rubber-lined straight-through valves are ideal for tough industrial applications. You'll find them in chemical plants handling acids, power plants managing ash slurry, and wastewater treatment facilities controlling sludge and chemicals. Their robust, corrosion-resistant design makes them a reliable choice for these demanding environments.

Because of their unique design, these valves have become essential in several key industries. The combination of a straight flow path and a protective rubber lining makes them perfect for media that is both corrosive and abrasive. Here are the main areas where I see our clients using them.

Chemical and Petrochemical Industries

In chemical plants, you're dealing with a huge range of aggressive media. Acids, alkalis, and solvents can quickly destroy metal. The rubber lining in our valves acts as a barrier, protecting the cast iron or ductile iron body from chemical attack. The diaphragm[^2] also isolates all the moving parts of the valve from the fluid, so there's no risk of contamination or seizure. This zero-leakage performance is critical for both safety and preventing the loss of expensive chemicals.

Power Plants and Mining

Power plants, especially those with Flue Gas Desulfurization (FGD) systems, handle abrasive limestone and gypsum slurries. Mining operations move ore slurries with high solids content. In these applications, abrasion is the enemy. A standard valve would wear out in no time. The straight flow path of our valves minimizes turbulence and wear, while the thick rubber lining is tough enough to withstand the constant friction of the particles. It's a cost-effective and durable solution.

Water and Wastewater Treatment

Wastewater plants are a perfect example of where these valves shine. They are used to control the flow of sludge, dose chemicals like sodium hypochlorite for disinfection, and manage various treatment processes. The valve has no dead spots where sludge can accumulate and go septic. The EPDM rubber[^6] lining offers excellent resistance to the chemicals used in water treatment. It’s a reliable, low-maintenance choice for a critical public utility.

| Industry | Common Application | Key Benefit |

|---|---|---|

| Chemical | Acid and alkali transfer | Corrosion resistance, zero leakage |

| Power Plant | Ash and limestone slurry | Abrasion resistance, non-clogging |

| Wastewater | Sludge and chemical dosing | No dead spots, chemical resistance |

| Mining | Ore slurry transport | Handles high solids content |

Why Is the Lining Material So Critical for Valve Performance?

Are you seeing premature valve failure due to corrosion? This is a common problem when the lining isn't right for the media. Choosing the correct lining is the key to longevity.

The lining is the valve's first line of defense. It isolates the metal valve body from corrosive or abrasive fluids. The right material, like EPDM or Butyl rubber, ensures chemical compatibility, prevents contamination, and extends the valve's service life, directly impacting system reliability and safety.

A diaphragm[^2] valve is only as good as its lining. The valve body, typically made of cost-effective cast iron (CI) or ductile iron (DI), provides the strength and structure. But it's the lining that does the hard work of protecting that structure from the process fluid. Getting this part right is everything.

Choosing the Right Rubber for the Job

We offer a range of rubber linings because there is no one-size-fits-all solution. The choice depends entirely on the chemical composition, temperature, and abrasive nature of your fluid. For a recent client in the chemical industry, we recommended an EPDM lining for their dilute acid lines because of its excellent chemical resistance and ability to handle temperatures up to 120°C. For another client handling oily waste, NBR was the better choice. We work with you to match the material to the application.

| Lining Material | Common Use Cases | Key Properties |

|---|---|---|

| EPDM | Water, wastewater, acids, alkalis | Excellent heat, water, and chemical resistance. |

| NBR (Buna-N) | Oils, fuels, solvents, grease | Excellent resistance to petroleum-based fluids. |

| Butyl | Gases, acids, esters | Very low gas permeability, good chemical resistance. |

| Natural Rubber | Abrasive slurries (soft or hard) | High resilience and excellent abrasion resistance. |

The Advantage of Seamless, Molded Linings

Here is a detail that many people overlook: how the lining is applied. Many manufacturers use sheets of rubber that they fit inside the valve and seam together. These seams are a weak point where failure often begins. At our factory, we use a mechanical molding process. The rubber is applied in a way that creates a single, seamless, and uniform layer. This lining is physically bonded to the metal body. It’s smoother, which reduces friction and buildup. It's also visually perfect, which is a sign of the overall quality. This method is more complex, but it results in a far more reliable and durable valve.

How Do We Ensure Quality in Our Straight-Through Diaphragm Valves?

Tired of suppliers delivering valves with casting defects and a poor finish? These quality issues reflect badly on your brand. We believe superior quality starts with a superior manufacturing process.

We ensure quality through meticulous control over our entire manufacturing process. We use resin-coated sand casting[^7] for flawless valve bodies, all-new molds for a perfect finish, and a mechanical lining process for a seamless, durable interior. This commitment to detail guarantees a reliable, high-performance product.

As a B2B manufacturer, I know that the quality of our product becomes the quality of your brand. That's why we don't cut corners. For our clients, who are often distributors or brands themselves, receiving a product that looks and performs flawlessly is non-negotiable. Here’s how we make that happen.

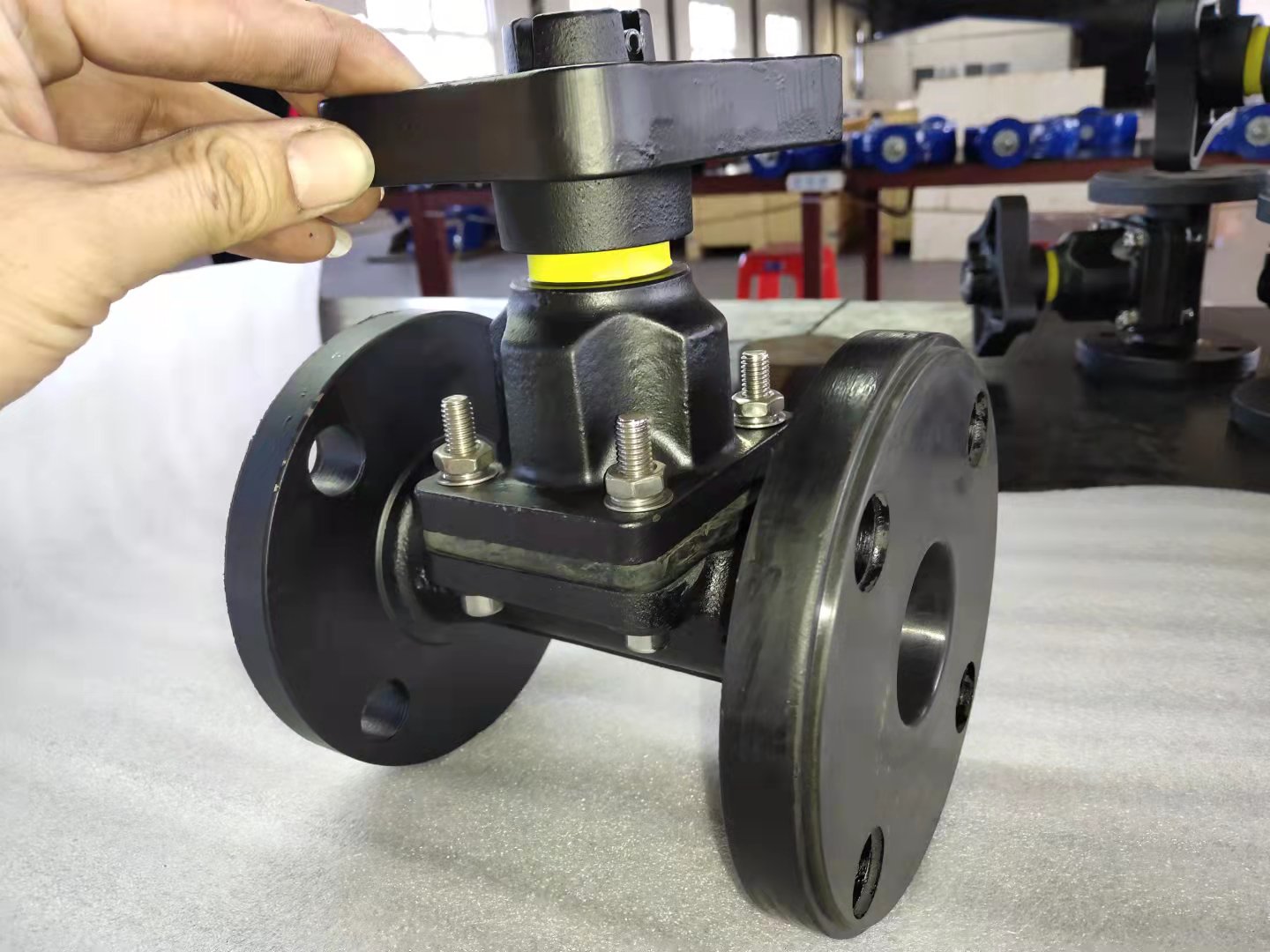

Superior Casting with the Resin-Coated Sand Process

The foundation of a great valve is a great casting. We use the resin-coated sand casting[^7] process for our valve bodies. In simple terms, this technique uses a special sand that creates an incredibly smooth and stable mold. The result is a valve body with a much finer surface finish and far fewer defects like pinholes or porosity. This isn't just about looking good. A cleaner casting has better structural integrity and provides a better surface for the rubber lining to bond to, which enhances the valve's overall lifespan and reliability.

Flawless Finish from All-New Molds

I’ve seen valves from other factories made with old, worn-out molds. The final products have inconsistent dimensions, rough surfaces, and visible defects. This is a sign of a factory cutting costs. We take the opposite approach. We invest in keeping our molds new and in perfect condition. This guarantees that every single valve body we produce is identical and has a clean, sharp, and professional appearance. When you're putting your brand name on a product, this level of visual quality is essential.

A Modern Design Aesthetic

Finally, we pay attention to design. Our valve designs are aligned with international aesthetics. They look modern and well-engineered because they are. When you place our valve next to one from a typical factory, the difference is immediately clear. Ours looks more robust and professional. For importers and international brands, this superior appearance makes the product easier to market and sell, inspiring confidence in the end-user before the valve is even installed.

Conclusion

In short, rubber-lined straight-through valves are your best choice for handling tough fluids. Their simple design, durable lining, and our quality manufacturing ensure reliable, long-lasting performance for your projects.

[^1]: Learn how straight-through diaphragm valves can enhance flow efficiency and reduce maintenance costs. [^2]: Learn about the mechanics of diaphragm operation and its role in valve performance. [^3]: Discover the unique features of full-bore valves that make them ideal for handling viscous fluids. [^4]: Learn about the key differences and advantages of straight-through valves over weir-type valves. [^5]: Explore the advantages of using rubber-lined valves for corrosive and abrasive environments. [^6]: Explore the benefits of EPDM rubber in ensuring chemical compatibility and durability. [^7]: Discover how resin-coated sand casting improves valve quality and performance.