Struggling to choose the right pneumatic valve? The options can feel overwhelming, and a wrong choice leads to system failure. Understanding the classifications simplifies the entire process.

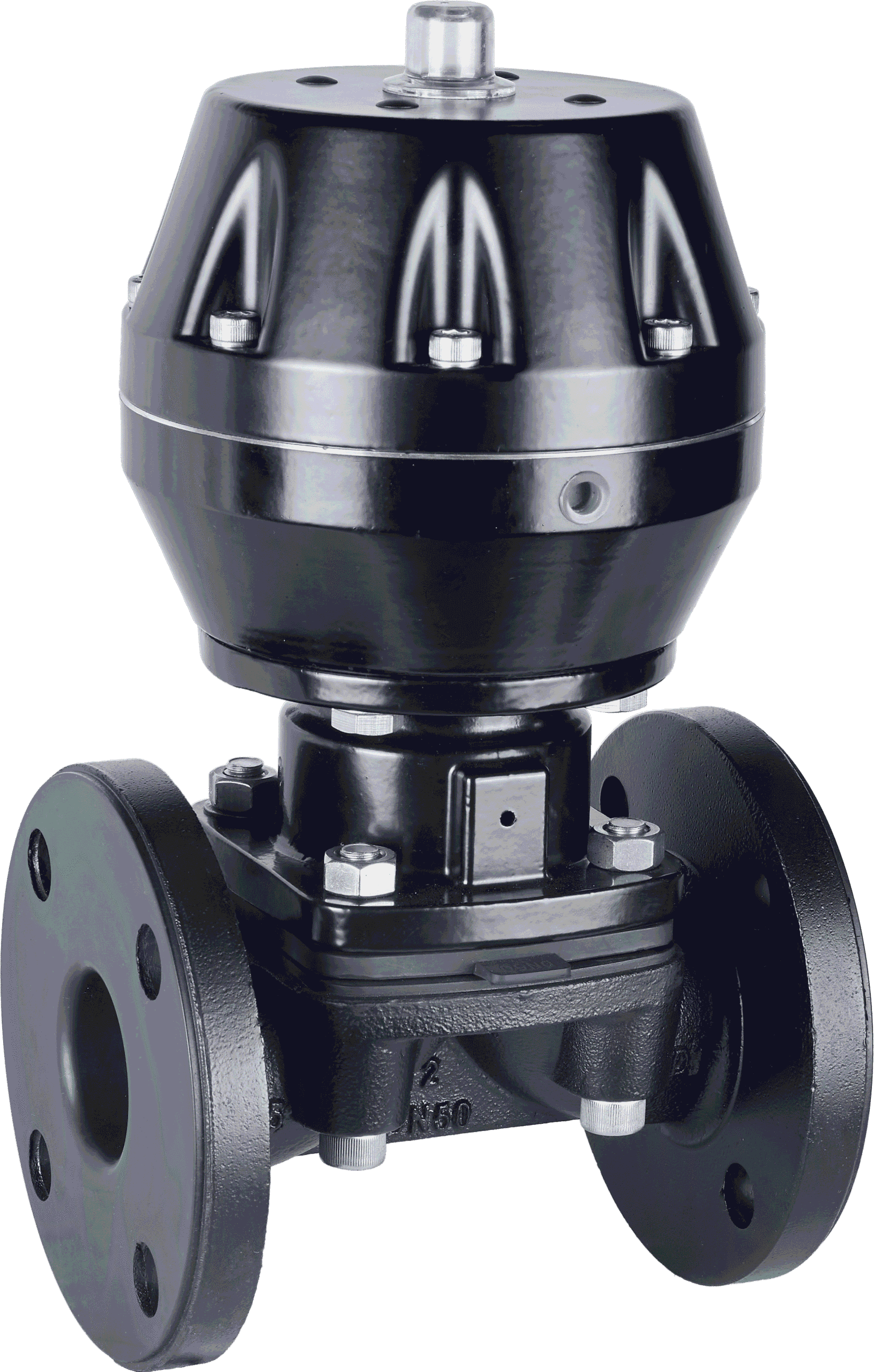

Pneumatic diaphragm valves[^1] are primarily classified by their actuator type[^2] (normally open, normally closed, double-acting), body design (weir or straight-through), internal lining material (rubber or plastic), and optional accessories like emergency handwheels or positioners for remote control.

Choosing the right pneumatic diaphragm valve is critical for any automated fluid control system. As a manufacturer, I've guided countless clients through this process. The key isn't to know every single detail but to understand the main categories. Once you grasp these fundamental differences, you can quickly narrow down the options to find the perfect fit for your application. Let's break down these classifications one by one so you can make your next selection with confidence.

What Are the Different Actuator Types for Pneumatic Diaphragm Valves?

Picking an actuator seems technical and confusing. But choosing the wrong "fail-safe" mode can disrupt your process or even cause a safety hazard during a power or air loss.

The three main actuator type[^2]s are Normally Closed (NC)[^3], which closes on air failure; Normally Open (NO)[^4], which opens on air failure; and Double-Acting (DA)[^5], which requires air to both open and close, holding its last position.

The actuator is the "brain" of the valve, telling it when to open and close. The most important question to ask is: "What should the valve do if the compressed air supply is suddenly cut off?" Your answer determines which type you need. Over the years, I've seen that the majority of applications, especially those involving hazardous chemicals, rely on the Normally Closed type for safety. However, some systems, like emergency cooling loops, require a Normally Open design. Double-Acting actuators offer great control for throttling applications where you need the valve to stay put if air is lost.

Actuator Types Explained

| Actuator Type | Action on Air Loss | Common Use Case |

|---|---|---|

| Normally Closed (NC)[^3] | Spring forces the valve closed. | Safety shut-off, dosing lines. Most common type. |

| Normally Open (NO)[^4] | Spring forces the valve open. | Emergency drains, cooling water systems. |

| Double-Acting (DA)[^5] | Stays in its last position. | Throttling, flow regulation, processes needing position hold. |

Weir vs. Straight-Through: Which Pneumatic Diaphragm Valve Body Is Right for You?

The valve body design might seem like a minor detail. However, the wrong choice can lead to clogging with slurries or poor flow control with clean liquids, hurting your efficiency.

Weir-type valves[^6] are best for precise control of clean or mildly corrosive fluids. Straight-through types have an unobstructed flow path, making them perfect for abrasive slurries, viscous media, or fluids with solids that would otherwise cause blockages.

When we design a valve for a client, the first thing we ask about after the medium is its consistency. Is it clean water or a thick, gritty slurry? The answer immediately points us to either a weir or straight-through design. A weir valve has a small "dam" inside that the diaphragm seals against. This is great for throttling and gives a very tight seal, which is why it's so popular in chemical plants and water treatment facilities. On the other hand, if you're dealing with something like mining ore slurry or wastewater sludge, you need a straight-through valve. It’s essentially a clear pipe, preventing anything from getting stuck.

Body Design Comparison

| Feature | Weir-Type | Straight-Through Type |

|---|---|---|

| Flow Path | Obstructed by a "weir" or dam. | Unobstructed, full-bore path. |

| Best For | Clean liquids, fine throttling control. | Abrasive slurries, viscous fluids, solids. |

| Applications | Chemical dosing, power plant water treatment. | Mining, wastewater sludge, flue gas desulfurization. |

How Do Lining Materials Affect Pneumatic Diaphragm Valve Selection?

With so many lining options, it's easy to get lost. But choosing a lining that can't handle your chemical medium will lead to rapid corrosion, leaks, and costly downtime.

The lining choice depends entirely on your process fluid. Rubber linings[^7] like EPDM or NBR are excellent for abrasion and general chemicals. Plastic linings[^8] like PFA or PTFE offer superior resistance to highly corrosive acids, solvents, and high-purity applications.

The lining is the valve's first line of defense, as it's the only part that touches the process fluid. I always tell my clients that this is where you can't afford to cut corners. For general-purpose applications like in a wastewater treatment plant, a cost-effective rubber lining like EPDM is often a perfect choice. But if you're moving aggressive acids in a chemical plant, you need the superior chemical barrier of a plastic lining like PTFE. At our factory, we use a mechanical application process for our linings, which creates a seamless, smooth surface that is more durable and performs better than many alternatives.

Lining Material Breakdown

| Lining Category | Key Advantage | Common Applications |

|---|---|---|

| Rubber Linings (EPDM, NBR, Butyl) | Excellent abrasion resistance, flexibility, and cost-effective. | Water treatment, slurries, general chemical use. |

| Plastic Linings (PFA, PTFE, ETFE) | Unmatched chemical resistance to strong acids and alkalis. | High-purity processes, aggressive chemical transfer, pharmaceuticals. |

What Custom Configurations Are Available for Pneumatic Diaphragm Valves?

Sometimes a standard, off-the-shelf valve just doesn't fit your system. You might be forced to compromise on manual control during a power outage, system monitoring, or actuator protection.

Valves can be customized with accessories. Common options include an emergency manual handwheel[^9] for power failures, an air filter regulator[^10] for clean air supply, and a limit switch box[^11] or positioner for remote feedback and precise automation.

As an OEM/ODM supplier, a huge part of what we do is building valves to a client's exact specifications. A standard valve is just the starting point. For instance, a client might need to operate a valve manually if their compressed air system goes down. In that case, we add an emergency handwheel. Another client running a fully automated plant will need remote feedback, so we install a limit switch box[^11] that signals to their control room whether the valve is open or closed. These accessories add cost, but they also add critical functionality and safety to a system. Our job is to help you find the right balance for your budget and operational needs.

Common Accessories and Their Functions

| Accessory | Function | Why You Might Need It |

|---|---|---|

| Emergency Handwheel | Allows manual opening/closing of the valve. | For critical valves that must be operated during an air supply failure. |

| Air Filter Regulator | Cleans and regulates pressure of the incoming air. | To protect the actuator from moisture/debris and ensure stable operation. |

| Limit Switch Box / Positioner | Sends an electrical signal confirming valve position. | For integration into an automated control system (PLC/DCS). |

Conclusion

Understanding how pneumatic diaphragm valves are classified by actuator, body, lining, and accessories makes selecting the right one simple, ensuring your system runs safely and efficiently.

[^1]: Explore this resource to understand the various applications and benefits of pneumatic diaphragm valves in fluid control systems. [^2]: Learn about actuator types to make informed decisions for your pneumatic valve selection. [^3]: Discover the safety features and applications of Normally Closed actuators in pneumatic systems. [^4]: Find out how Normally Open actuators function and their specific use cases in emergency systems. [^5]: Understand the advantages of Double-Acting actuators for precise control in various applications. [^6]: Explore the benefits of Weir-type valves for controlling clean or mildly corrosive fluids. [^7]: Explore the advantages of rubber linings for general-purpose applications in fluid control. [^8]: Learn about the superior chemical resistance of plastic linings for aggressive applications. [^9]: Understand the critical role of emergency handwheels in ensuring valve operation during failures. [^10]: Learn how air filter regulators protect pneumatic systems and ensure stable operation. [^11]: Discover how limit switch boxes enhance automation and feedback in pneumatic valve operations.