Struggling to choose the right valve? Making the wrong choice can lead to costly downtime and operational failures. We are here to clear up the confusion for you.

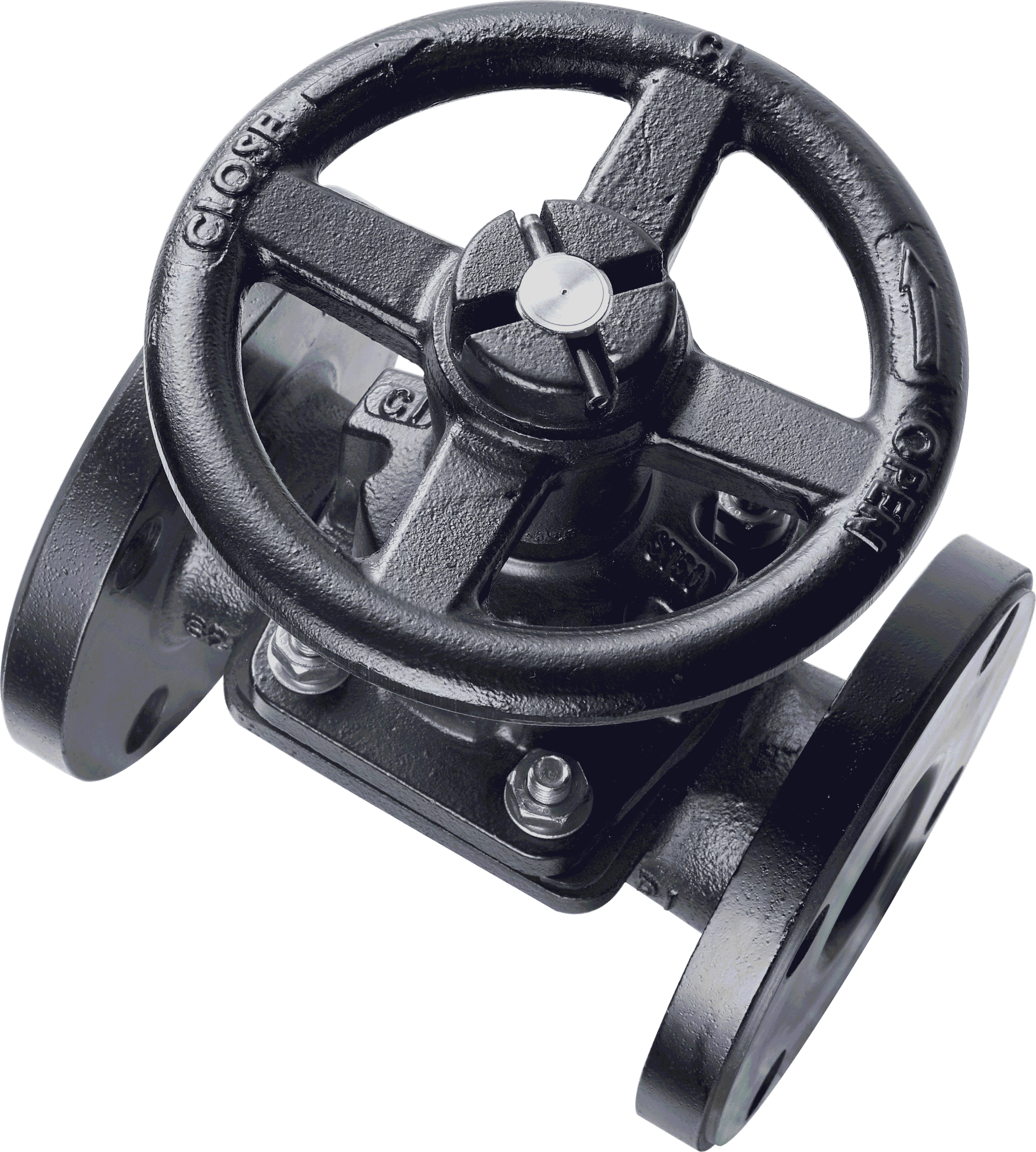

Diaphragm valves[^1] offer precise control[^2] for corrosive and abrasive fluids[^3]. Their lifespan depends on materials and operating conditions, and they differ from ball or butterfly valves[^4] in their unique sealing mechanism[^5].

Choosing the right valve is a big decision for any project manager or business owner. I get calls and emails all the time from clients who are trying to figure out if a diaphragm valve is the best fit for their needs. They are concerned about performance, longevity, and how it compares to other valve types they might be more familiar with. It's a critical choice that impacts efficiency, safety, and your bottom line. Let's walk through some of the most common questions I hear. This will help you make a more informed decision for your specific industrial application.

What is the expected lifespan[^6] of a diaphragm valve?

Worried about frequent valve replacements and the high costs involved? An unexpected failure can shut down your entire production line, leading to significant losses. Let's look at what determines longevity.

A diaphragm valve's lifespan depends on its design, materials, operating conditions, and maintenance. A high-quality valve can last for many years, but harsh chemicals or extreme temperatures can shorten its life.

When a customer asks me about lifespan, I always explain it's not a single number. It's a result of several key factors working together. As a manufacturer, we see this firsthand. For example, the choice of lining is critical. A rubber lining like EPDM[^7] is great for water treatment, but it won't last long against aggressive acids. For that, you'd need a plastic lining like PTFE[^8]. The quality of the valve body also matters. We use a resin-coated sand casting[^9] process for our CI and DI bodies. This creates a smoother surface with fewer defects, which helps the lining adhere perfectly and resist wear. Our mechanically applied linings[^10] are seamless, which is a big advantage over other methods that can leave weak spots. Think of it like this: a well-built valve in the right application is a long-term investment.

| Factor | Impact on Lifespan | Our Advantage |

|---|---|---|

| Lining Material | The most critical factor for chemical and abrasion resistance. | We offer a full range of rubber and plastic linings. |

| Operating Conditions | High pressure, extreme temperatures, and abrasive slurries increase wear. | Our valves are designed for medium-to-low pressure, highly corrosive jobs. |

| Build Quality | Poor casting or lining application leads to premature failure. | Resin-coated sand casting and seamless linings ensure durability. |

| Maintenance | Regular inspection and diaphragm replacement can greatly extend valve life. | Our design allows for simple, in-line maintenance. |

What's the difference between a ball valve[^11] and a diaphragm valve?

Are you unsure which valve type fits your needs? Choosing the wrong one can cause poor flow control or, even worse, dangerous leaks with corrosive fluids. Let's compare them.

The main difference is their flow control method. A ball valve[^11] uses a rotating ball for quick on/off action. A diaphragm valve uses a flexible diaphragm for precise control[^2], making it better for corrosive or viscous fluids.

I often explain this difference to procurement managers who are used to general-purpose ball valve[^11]s. A ball valve[^11] is simple and effective for on/off control of clean liquids, like a water main. It has a ball with a hole through it that rotates to open or close the path. It's fast, but not great for regulating flow. A diaphragm valve is completely different. It has a flexible diaphragm that is pushed down onto a weir (a raised lip) to seal. This mechanism completely isolates the fluid from the valve's moving parts. This is a huge benefit in the chemical industry. There are no crevices for material to get trapped, and the fluid never touches the valve stem or actuator. This makes it ideal for handling aggressive chemicals, slurries, and anything where you can't risk contamination or leaks.

| Feature | Ball Valve | Diaphragm Valve |

|---|---|---|

| Control Type | Quarter-turn (On/Off) | Linear (Precise Throttling) |

| Best For | Clean liquids, high pressure | Corrosive fluids, slurries, precise dosing |

| Sealing | Good, but can have dead space | Excellent, leak-proof, no contamination |

| Maintenance | Often requires removal from line | Diaphragm can be replaced in-line |

How are diaphragm valves and butterfly valves[^4] different?

Choosing between two common industrial valves can be tough. A poor fit can impact flow efficiency and sealing integrity, especially in large-scale operations. Here is a clear breakdown.

Diaphragm valves[^1] use a flexible membrane for precise flow regulation and a tight seal. In contrast, butterfly valves[^4] use a rotating disc and are better suited for high flow rates in larger pipes.

This question comes up a lot when we talk with clients from power plants or wastewater treatment facilities. They often use large-diameter pipes where butterfly valves[^4] are common. A butterfly valve is essentially a disc mounted on a rod. When the rod rotates, the disc turns to open or close the flow. They are simple, lightweight, and cost-effective for large pipes. However, the disc is always in the flow path, which can cause some pressure drop and turbulence. More importantly, their sealing isn't as tight as a diaphragm valve's. For applications like flue gas desulfurization[^12] (FGD) where you have an abrasive limestone slurry, the tight, isolated seal of a diaphragm valve is far superior. It prevents leaks and handles the abrasive media without wearing out the sealing surfaces quickly. Our cast iron body diaphragm valves are a perfect, cost-effective solution for these tough slurry applications.

| Feature | Butterfly Valve | Diaphragm Valve |

|---|---|---|

| Mechanism | Rotating Disc | Flexible Diaphragm |

| Best For | High flow, large pipes (e.g., water mains) | Corrosive/abrasive media, tight shut-off[^13] |

| Flow Path | Disc obstructs flow slightly | Smooth, weir-type path when open |

| Sealing | Good, but can wear with abrasives | Bubble-tight, excellent for hazardous media[^14] |

Conclusion

In short, diaphragm valves excel at precise control[^2] of tough fluids. Their lifespan is determined by material and use, and their unique design offers superior sealing over other valve types.

[^1]: Understanding the benefits of diaphragm valves can help you make informed decisions for handling corrosive and abrasive fluids effectively. [^2]: Learn how diaphragm valves offer precise control, crucial for applications requiring accurate flow regulation and safety. [^3]: Explore why diaphragm valves are ideal for handling challenging fluids, ensuring durability and performance in harsh conditions. [^4]: Learn about the differences between butterfly and diaphragm valves to select the best option for high flow or precise control needs. [^5]: Discover the unique sealing mechanism of diaphragm valves that ensures leak-proof operation, essential for safety and efficiency. [^6]: Understanding the factors affecting diaphragm valve lifespan can help in planning maintenance and reducing unexpected failures. [^7]: Learn about the benefits of EPDM rubber lining for water treatment applications, enhancing valve longevity and performance. [^8]: Explore the advantages of PTFE lining in resisting aggressive acids, crucial for maintaining valve integrity and safety. [^9]: Understand how resin-coated sand casting enhances valve durability, ensuring a smoother surface and better lining adhesion. [^10]: Discover how mechanically applied linings provide seamless protection, reducing weak spots and extending valve life. [^11]: Compare ball valves and diaphragm valves to choose the right one for your application, focusing on flow control and sealing. [^12]: Explore why diaphragm valves are ideal for handling abrasive slurries in FGD, ensuring tight sealing and durability. [^13]: Understand the importance of tight shut-off in diaphragm valves for preventing leaks and ensuring safe operation. [^14]: Discover how diaphragm valves provide safe and reliable handling of hazardous media, crucial for industrial safety.