Struggling with valves that can't handle your demanding process fluids? Failures cause costly downtime and safety risks. You need a single, reliable solution that adapts to different industrial challenges.

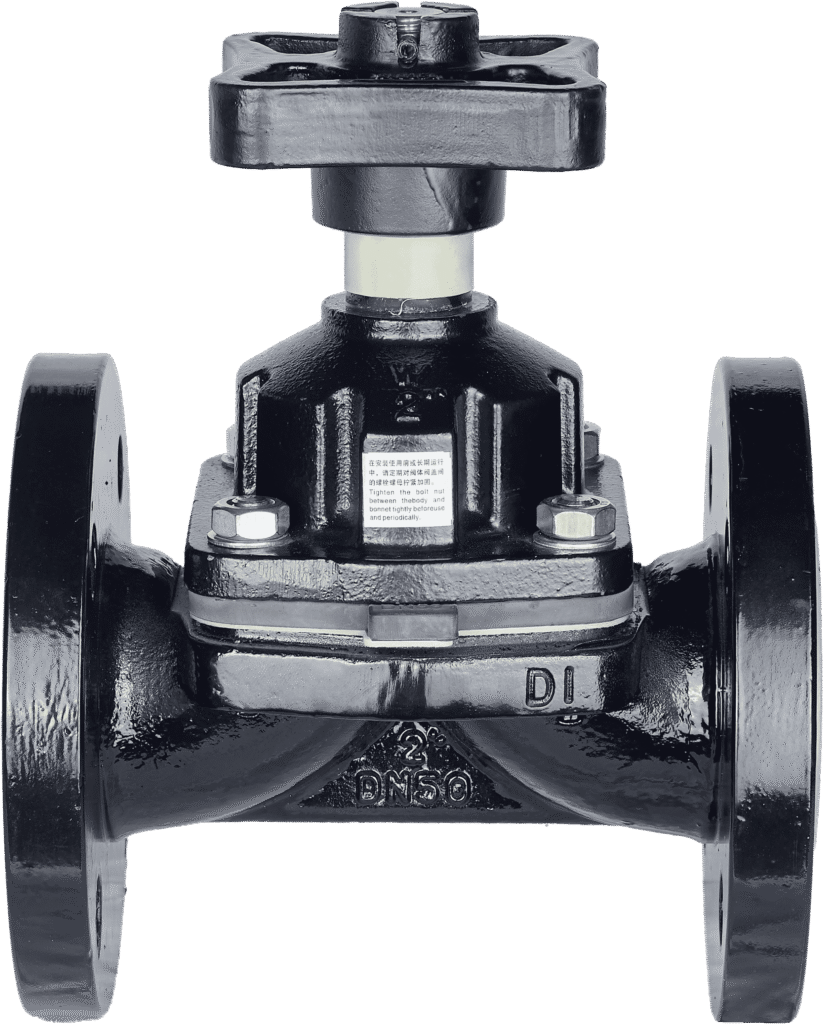

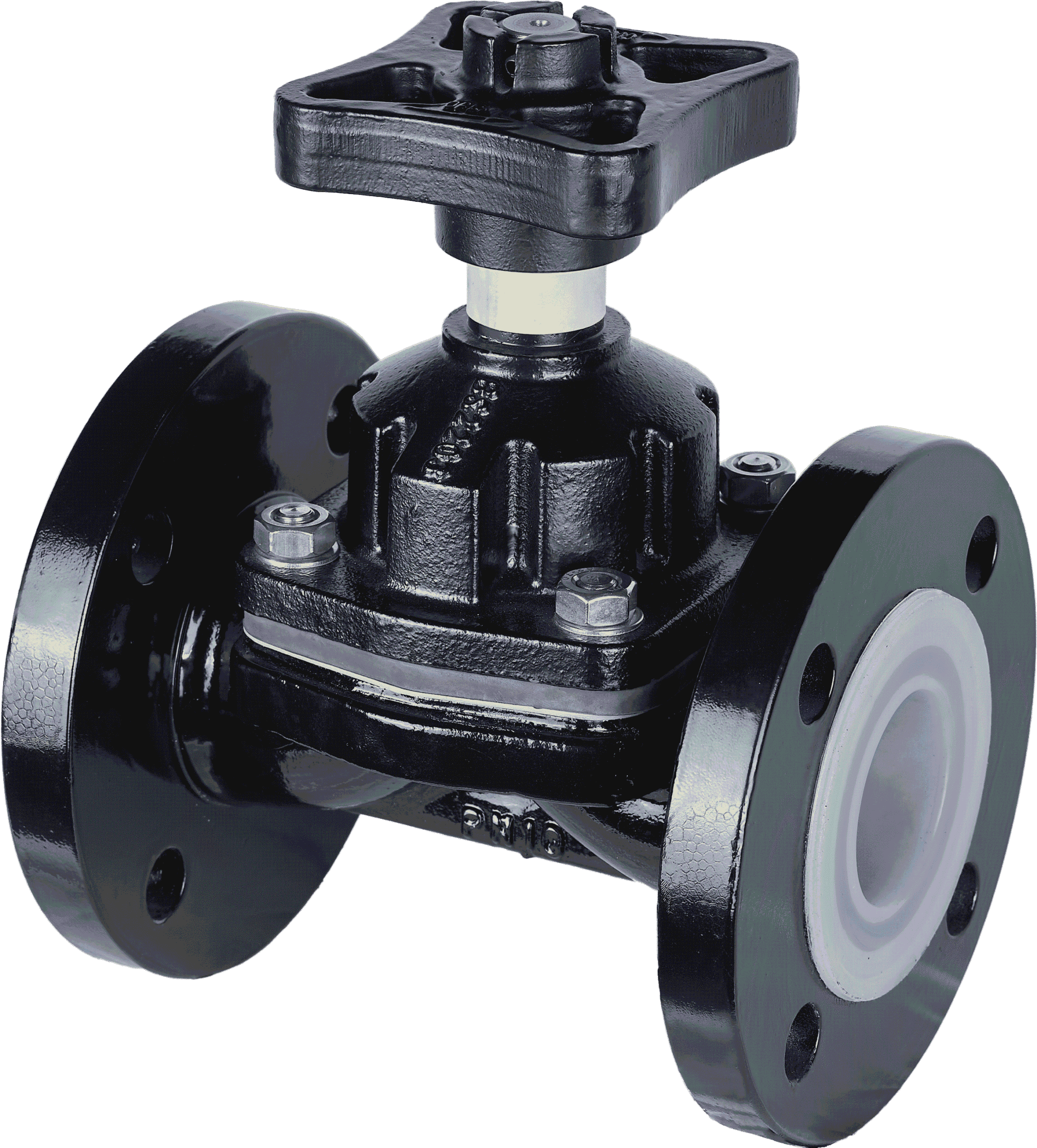

Lined diaphragm valves are versatile because their design isolates the process fluid from the valve's working parts using a flexible diaphragm and a protective lining. With various lining materials, they safely handle corrosive chemicals[^1], abrasive slurries[^2], and high-purity liquids, ensuring reliability across many industries.

I've been in the valve manufacturing business for years, and I've seen firsthand how a single component can make or break an entire industrial process. The search for a "one-size-fits-all" valve is often frustrating for plant managers and engineers. But the lined diaphragm valve comes impressively close. Its clever design is the key to its incredible adaptability. Let's explore exactly how this valve tackles some of the toughest jobs in industry, from handling aggressive chemicals to controlling abrasive slurries[^2]. It’s a journey into smart engineering that solves real-world problems for our clients every day.

How Do Lined Diaphragm Valves Handle Corrosive Chemicals So Effectively?

Aggressive chemicals corrode standard valves, leading to dangerous leaks and safety hazards. This constant replacement cycle is expensive and disruptive. You need a valve that offers superior, long-lasting chemical resistance[^3].

They handle corrosive chemicals[^1] by using inert linings like PFA[^4], PTFE[^5], or specific rubbers. This lining creates a complete barrier, isolating the fluid from the metal valve body. The diaphragm seal further prevents any media from reaching the operating mechanism, ensuring leak-free, durable performance.

In the chemical industry, containment is everything. A small leak isn't just a maintenance issue; it can be a major safety and environmental disaster. I remember a client who ran a specialty chemical plant. They were replacing their transfer line valves every six months due to corrosion from concentrated acids. The cost and downtime were becoming unsustainable. We introduced them to our PFA[^4]-lined diaphragm valves[^6]. The core of their effectiveness lies in the lining. This is a non-reactive layer that completely shields the valve's structural cast iron or ductile iron body from the harsh media. Think of it as a perfectly fitted suit of armor for the valve's interior. Our advantage is that we apply these linings mechanically, which creates a seamless, smooth surface with no weak points, unlike some other methods. This, combined with the diaphragm that isolates the bonnet assembly, creates a fortress against corrosion.

Key Lining Materials for Chemical Resistance

The choice of lining is critical and depends entirely on the specific chemical application. Here’s a simple breakdown of the most common options we provide:

| Lining Material | Best For | Key Advantages |

|---|---|---|

| PFA[^4]/PTFE[^5] | Strong acids, alkalis, solvents, high-purity media | Near-universal chemical inertness, high-temperature resistance, smooth surface. |

| EPDM Rubber[^7] | Dilute acids, alkalis, water treatment[^8] chemicals | Excellent flexibility, good abrasion resistance, cost-effective for many uses. |

| NBR Rubber[^9] | Oils, fuels, and some solvents | Superior resistance to petroleum-based fluids. |

| Natural Rubber[^10] | Abrasive slurries with some chemicals | Excellent abrasion resistance and good general chemical resistance[^3]. |

By matching the right lining to the application, we provide our clients with a solution that doesn't just work, but lasts, turning a recurring problem into a long-term, reliable asset.

What Makes Diaphragm Valves Ideal for Abrasive Slurries?

Abrasive slurries in mining or power plants quickly wear down valve components. This erosion causes poor sealing, frequent maintenance, and costly plant shutdowns. You need a valve built to withstand this constant punishment.

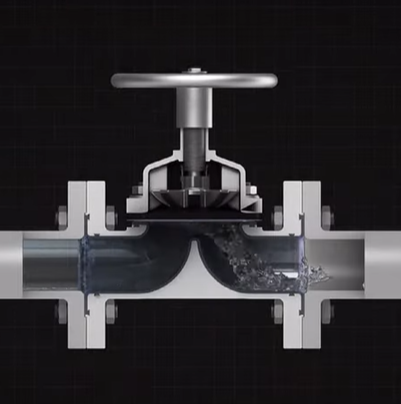

Diaphragm valves are ideal for abrasive slurries[^2] because they feature a smooth, pocketless flow path that minimizes turbulence and wear. The resilient rubber lining and diaphragm absorb the impact of particles, providing excellent abrasion resistance and ensuring a tight shutoff even with solids present.

When you're moving fluids filled with sand, ash, or ore particles, it’s like liquid sandpaper flowing through your pipes. Many valve designs, like ball or gate valves, have cavities and complex shapes where these particles can get trapped. This not only causes them to wear out quickly but can also prevent the valve from closing completely. I once visited a flue gas desulfurization (FGD) unit at a power plant where they were struggling with limestone slurry lines. Their valves were failing constantly. The solution was the weir-style diaphragm valve. Its design is brilliantly simple. It has a raised "weir" in the middle, and the diaphragm pushes down onto it to close. This creates a streamlined path for the slurry to flow over, with no sharp turns or dead spots for particles to accumulate and cause damage. The soft rubber lining we use also acts like a shock absorber[^11], cushioning the impact of the abrasive particles and extending the valve's life significantly.

Comparing Valve Types for Slurry Service

Not all valves are created equal when it comes to handling solids. The design makes a huge difference in performance and longevity.

| Valve Type | Slurry Handling Performance | Main Drawback for Slurries |

|---|---|---|

| Diaphragm Valve | Excellent. Smooth flow path, no dead spots. Resilient lining absorbs abrasion. Tight shutoff. | Limited to lower pressures and temperatures compared to some metal-seated valves. |

| Ball Valve | Fair to Poor. Seats are prone to scratching and erosion by particles, leading to leaks. Cavity can trap solids. | Trapped slurry can damage the ball and seats, preventing tight shutoff. |

| Gate Valve | Poor. The gate slides into a groove that easily gets clogged with solids, preventing the valve from closing fully. | Clogging and seat erosion are very common, leading to high maintenance. |

| Pinch Valve | Excellent. Full-bore, straight-through design with a replaceable rubber sleeve that is highly resistant to abrasion. | The sleeve is the only wetted part, but can have limitations with certain chemicals or vacuum. |

For many low-to-medium pressure slurry applications in power, mining, and chemical processing, the diaphragm valve offers the best balance of performance, reliability, and cost-effectiveness. Our robust cast iron bodies are perfect for these large-scale systems.

Why Are Diaphragm Valves a Top Choice for Water Treatment Systems?

Dosing chemicals accurately in water treatment[^8] is critical for public health and compliance. Inconsistent flow or leaks can compromise water quality, create safety hazards, and waste expensive chemicals.

Diaphragm valves are a top choice for water treatment[^8] because they provide bubble-tight shutoff[^12] and precise throttling control[^13]. The diaphragm isolates the media, preventing contamination and leaks of chemicals like sodium hypochlorite. EPDM rubber linings offer excellent, cost-effective resistance to common water treatment[^8] chemicals.

Water and wastewater treatment[^8] plants are complex facilities that rely on the precise addition of various chemicals. From coagulants and flocculants to disinfectants and pH adjusters, every drop counts. I've worked with numerous municipal water authorities and industrial clients on their treatment facilities. A recurring theme is the need for absolute reliability in their dosing systems. A valve that leaks sodium hypochlorite is not only wasteful but also a significant safety risk. A valve that doesn't shut off completely can lead to an overdose of chemicals, affecting final water quality. This is where the diaphragm valve shines. Its mechanism provides a guaranteed leak-proof seal, both to the outside environment and downstream when closed. The gentle closing action also allows for excellent throttling, so operators can dial in the exact flow rate they need. It's a simple, robust, and safe choice for a critical application.

Diaphragm Valve Applications in a Treatment Plant

The versatility of the diaphragm valve means it can be used in multiple stages throughout a water or wastewater treatment[^8] facility.

| Treatment Stage | Application | Why Diaphragm Valve is a Good Fit |

|---|---|---|

| Intake / Pre-treatment | Raw water lines, grit removal | Handles water with high suspended solids. Abrasion-resistant rubber linings. |

| Chemical Dosing | Dosing acids, alkalis, coagulants, chlorine | Excellent chemical resistance[^3] (EPDM), precise flow control, and leak-proof seal. |

| Sludge Handling | Sludge return lines, sludge discharge | Manages abrasive and thick media without clogging. Easy to maintain. |

| Effluent Discharge | Final treated water lines | Provides reliable shutoff. Cost-effective for large diameter pipes. |

Whether it's a small manual valve for taking samples or a large pneumatically actuated valve on a main process line, the fundamental design provides the same level of reliability. This consistency is why so many engineers and operators in the water industry trust them.

How Does a Diaphragm Valve's Design Ensure Reliability and Precision?

Unreliable valves cause unexpected failures and process interruptions. You worry about inconsistent performance and product quality. A valve's core design should guarantee dependability from the start.

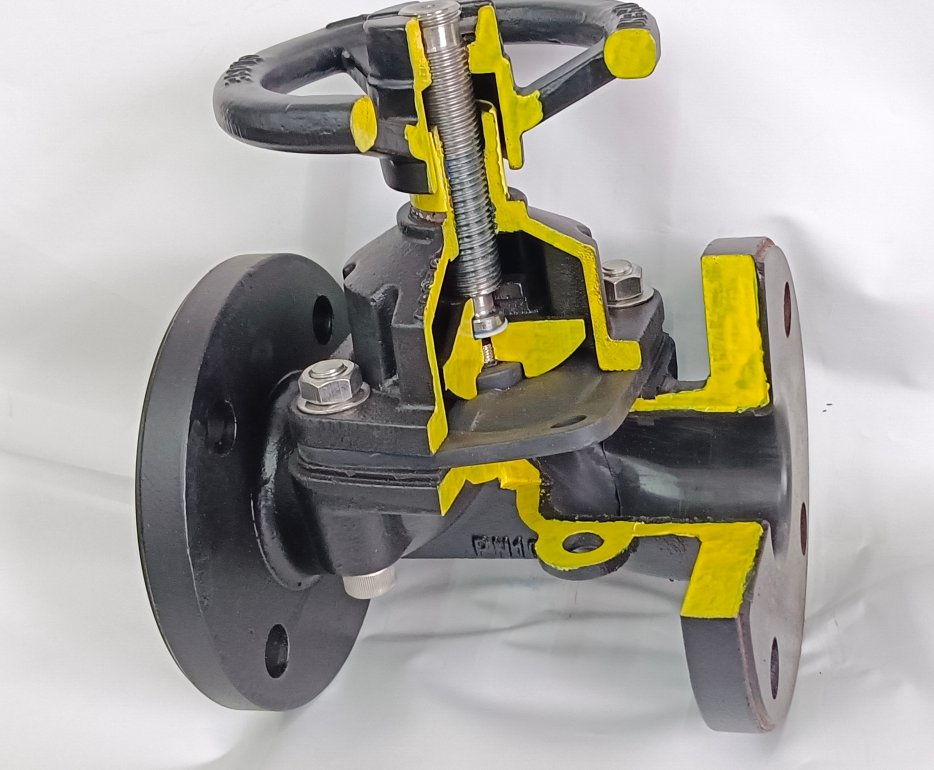

A diaphragm valve's design ensures reliability by having only one moving part in contact with the fluid: the diaphragm. This simplicity reduces wear points. The operating mechanism is completely isolated from the fluid, protecting it from corrosion or clogging and allowing for consistent, precise control.

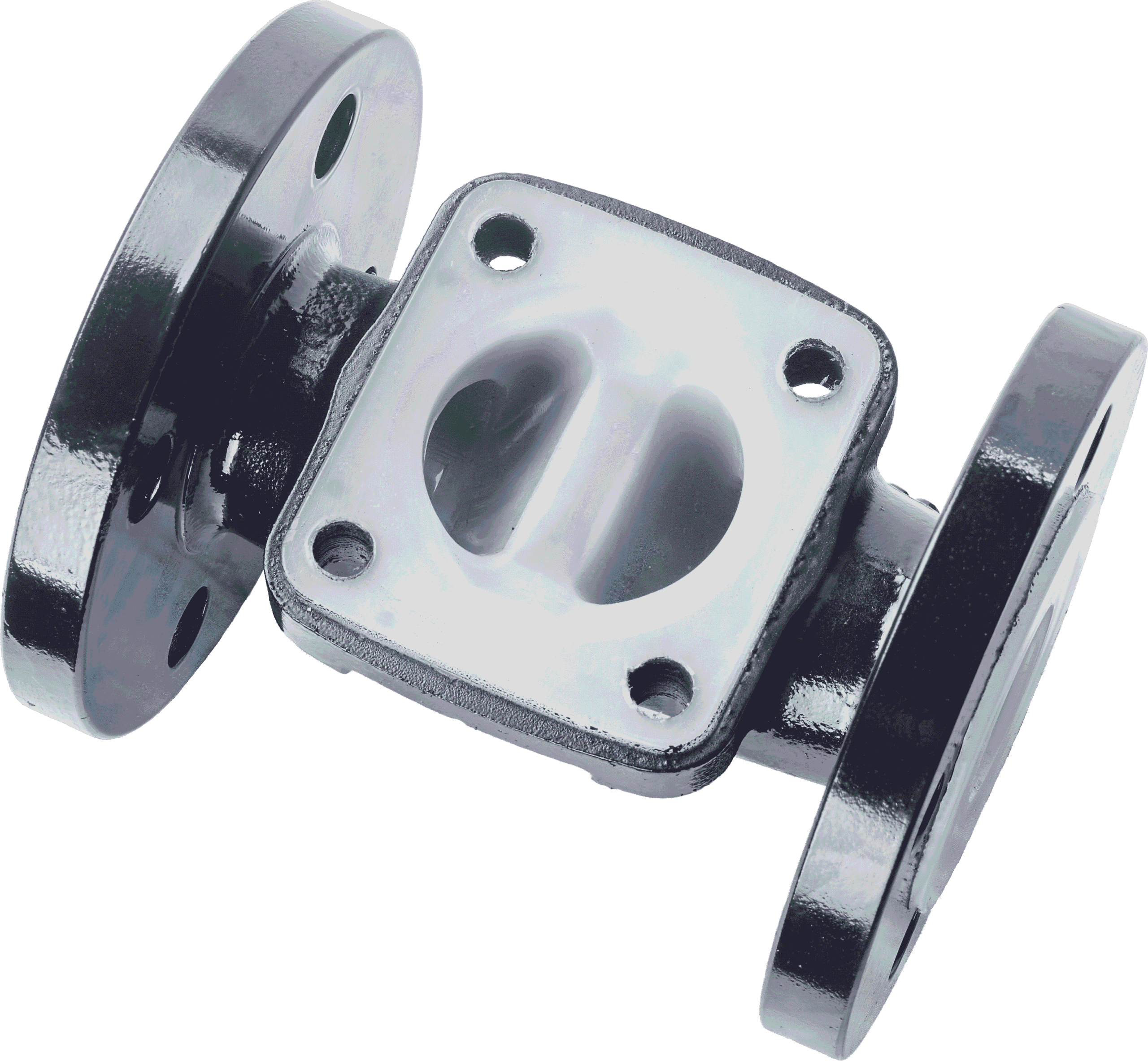

As a manufacturer, I am obsessed with design because it is the foundation of quality. A product can't be reliable if its design is flawed. The genius of the diaphragm valve is its simplicity. Inside the valve, the only wetted component that moves is the diaphragm itself. There are no complex linkages, rotating stems, or hidden cavities exposed to the process fluid. This minimalist approach drastically reduces the number of things that can go wrong. The entire bonnet assembly—the handwheel or actuator and the stem—is kept clean and dry, completely separated from the fluid. This means it won't corrode or get clogged, ensuring smooth operation for years. This is also why we invest heavily in our manufacturing process. We use resin-coated sand casting[^14] and all-new molds to produce valve bodies with a flawless surface finish. Our mechanically applied linings[^15] are perfectly smooth and seamless. This attention to detail at the manufacturing level ensures that the simple, reliable design of the diaphragm valve is executed perfectly.

Anatomy of a Reliable Diaphragm Valve

Every component plays a role in the valve's overall performance. As an OEM/ODM supplier, we give our clients full control over these components to build the perfect valve for their brand.

| Component | Our Quality Focus | Contribution to Reliability |

|---|---|---|

| Valve Body | Resin-sand cast CI/DI for a smooth, defect-free finish. | Provides a strong, pressure-containing housing with a perfect surface for lining adhesion. |

| Lining | Mechanically applied PFA[^4], PTFE[^5], or rubber for a seamless, uniform barrier. | The first line of defense against corrosion and abrasion, protecting the valve body and ensuring long life. |

| Diaphragm | High-grade elastomers and PTFE[^5] composites for optimal flexibility and strength. | Acts as both the flow control element and the primary seal, isolating the operating mechanism for ultimate reliability. |

| Bonnet/Actuator | Robust construction for manual (handwheel) or pneumatic operation. | Provides the force to operate the valve consistently and precisely, whether controlled by hand or an automated system. |

This holistic approach, from a brilliant core design to meticulous manufacturing, is how we deliver a product that our clients—distributors, brands, and importers—can stake their own reputations on.

Conclusion

Lined diaphragm valves are incredibly versatile. Their unique design and material options make them a reliable, high-performance solution for chemicals, slurries, and water treatment[^8], ensuring process safety and efficiency.

[^1]: Learn about the unique features that allow these valves to withstand aggressive chemicals. [^2]: Find out how diaphragm valves are designed to manage abrasive materials without failure. [^3]: Discover the materials that ensure long-lasting performance in harsh chemical environments. [^4]: Get insights into the advantages of using PFA linings in valve applications. [^5]: Explore the properties of PTFE that make it a popular choice for valve linings. [^6]: Explore how lined diaphragm valves can enhance reliability and performance in various industrial settings. [^7]: Learn about the versatility and advantages of EPDM rubber in various valve applications. [^8]: Understand the role of diaphragm valves in ensuring safe and efficient water treatment. [^9]: Discover the unique properties of NBR rubber that enhance valve performance with petroleum products. [^10]: Find out why natural rubber is effective for handling abrasive materials in valves. [^11]: Discover the design features that allow diaphragm valves to absorb impacts from abrasive particles. [^12]: Understand the importance of bubble-tight shutoff for safety and efficiency in fluid control. [^13]: Learn how diaphragm valves enable accurate flow regulation in various applications. [^14]: Understand how this manufacturing process improves the quality and performance of valves. [^15]: Explore the benefits of using mechanically applied linings for enhanced valve durability.