Tired of your valves failing from corrosion? The constant downtime and replacement costs are frustrating. There is a much more reliable solution that I've come to depend on.

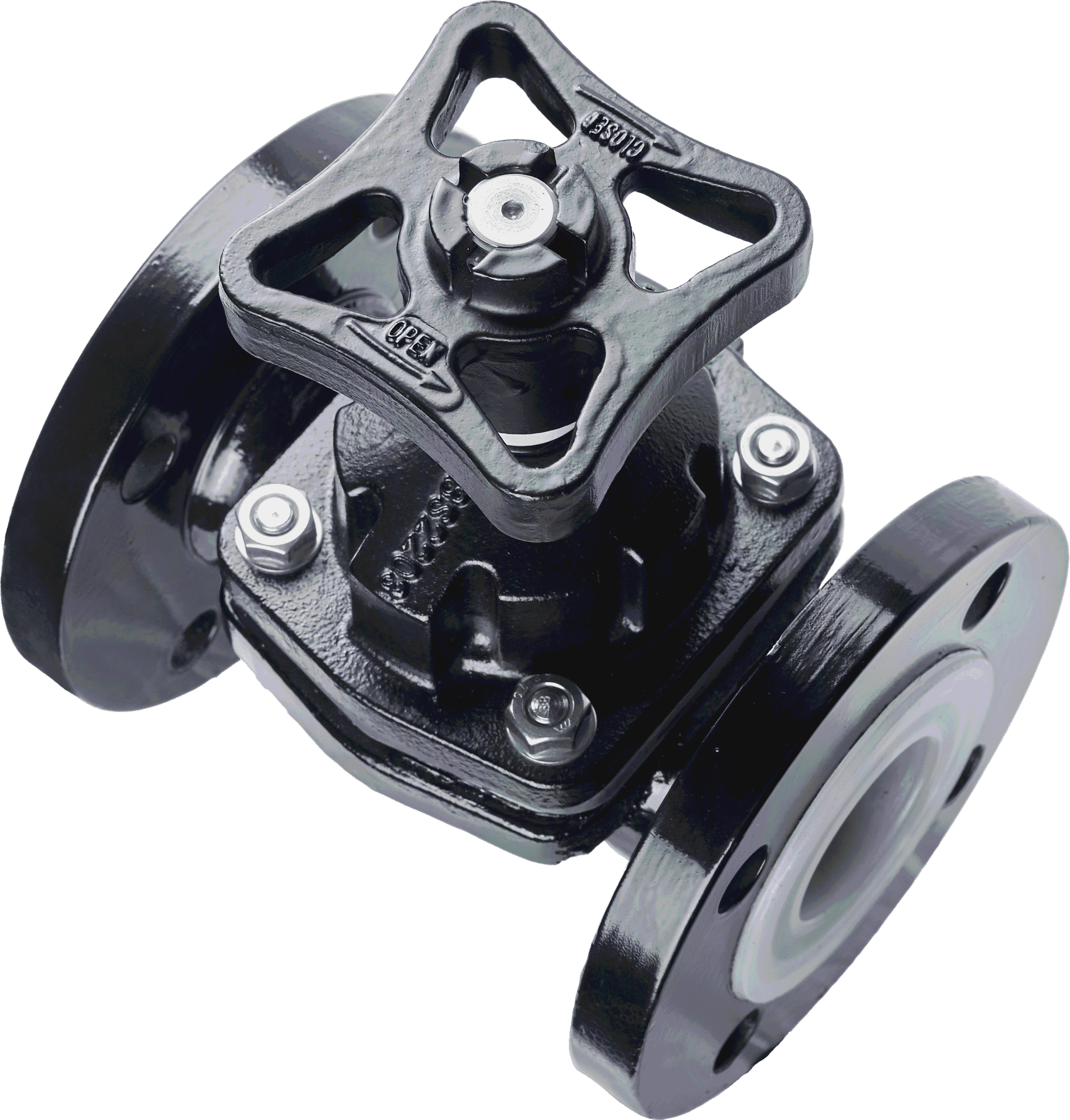

Fluorine-lined diaphragm valves[^1] are essential because they use a PTFE or FEP lining to completely isolate corrosive wastewater[^2] from the valve body[^3]. This dual protection prevents leaks, stops clogging, and extends service life from months to years, dramatically cutting maintenance and environmental risks.

I’ve seen firsthand how choosing the right valve can completely change an operation. For years, we struggled with standard carbon steel and stainless steel valves in our systems. They would corrode and start leaking within three to six months. It was a constant cycle of replacement and repair. Then we switched to fluorine-lined diaphragm valves, and the problems disappeared. They aren't just an optional upgrade; they are a fundamental requirement for handling the harsh chemicals in wastewater. Let's dive deeper into why this technology is so effective.

How Do These Valves Prevent Leaks and Clogging So Effectively?

Worried about hazardous leaks and system shutdowns from clogged valves? These common problems create huge environmental risks and operational headaches, which I know all too well.

They work through a dual-protection design. A flexible diaphragm creates a true zero-leak seal, while the super-smooth fluorine lining offers a non-stick, pocketless flow path. This combination completely prevents media from leaking out or building up inside, ensuring continuous, safe operation.

The secret to their success is a design that tackles the two biggest pain points in wastewater treatment[^4] head-on. I like to call it the “dual-layer defense” strategy.

First, you have total media isolation. The inside of the valve body[^3] is lined with a seamless layer of chemically inert plastic, like PTFE or FEP. On top of that, a tough PTFE diaphragm acts as the sealing element. This setup creates an impenetrable barrier. Corrosive media like acids, alkalis, chlorine disinfectants, and sulfides never touch the metal valve body[^3]. This is why a standard valve fails in months, while a fluorine-lined one can easily last three to five years. It stops corrosion before it can even start.

Second, the design ensures uninterrupted flow. The flow path inside the valve is incredibly smooth and has no cavities or dead spots. In my experience, this is a game-changer. Sludge, slurries, and other solids have nowhere to hide or build up. This feature drastically reduces the risk of clogging, which is a major cause of system downtime. The result is a valve that not only resists chemical attack but also keeps your process running smoothly without constant interruptions for cleaning.

How Do You Choose the Right Valve for Different Treatment Stages?

Choosing the wrong valve for a specific application can lead to poor performance and early failure. How do you make sure you match the valve to the job?

You must match the valve type to the specific task. For chemical dosing, use small, regulating valves for precision. For sludge, use large, straight-through valves to handle solids. For hazardous areas, always choose explosion-proof pneumatic models to meet safety standards.

A wastewater treatment[^4] plant has several different processes, and a one-size-fits-all approach to valves just doesn't work. You have to think about the specific function of each line to select the right valve. Based on my experience, here is a simple guide to help you choose correctly.

1. Chemical Dosing Systems

In this stage, you are adding chemicals like sulfuric acid, sodium hypochlorite, or flocculants. Accuracy is critical. You need a valve that offers precise control to avoid wasting expensive chemicals and to ensure the treatment process is optimized. For this, a small-bore, weir-type diaphragm valve is the best choice. The weir design allows for fine-tuned flow regulation, giving you exact control over the dosing rate.

2. Sludge and Slurry Transfer

Sludge is thick, abrasive, and full of solids. The main goal here is to keep things moving and avoid clogs at all costs. A large-bore, straight-through diaphragm valve is perfect for this job. It provides a wide-open, unobstructed path that lets the thick media flow freely without getting stuck. The durable lining also does an excellent job of resisting abrasion from the solid particles in the sludge.

3. Hazardous Environments

If your plant processes industrial wastewater, especially from petrochemical facilities, you may have areas with flammable or explosive atmospheres. Safety is the number one priority. In these zones, you must use a pneumatic diaphragm valve[^5] equipped with an explosion-proof actuator and solenoid. This ensures your equipment complies with all safety regulations and protects your personnel and facility.

Are Fluorine-Lined Valves Really More Cost-Effective?

The higher initial price of fluorine-lined valves makes some people hesitate. Is it truly a smart financial decision in the long run?

Absolutely. While the upfront cost is higher, the total cost of ownership is 40-60% lower than standard valves. You save a huge amount on frequent replacements, constant maintenance labor, and costly downtime. It's a classic case of investing a little more now to save a lot later.

Let's break down the costs, because this is where the real value becomes clear. I used to use standard metal valves, and it felt like we were constantly bleeding money. We replaced them every few months. That meant paying for a new valve, paying for the labor to install it, and, most importantly, losing money every minute the line was shut down.

With a fluorine-lined diaphragm valve, you pay more at the beginning. But that valve body[^3] will last for years. The only part that needs periodic replacement is the diaphragm, which is a low-cost wear part. Swapping out a diaphragm is a quick and simple job that can often be done without even removing the valve from the pipeline. When you look at the total costs over a five-year period, the savings are undeniable.

| Cost Factor | Standard Metal Valve | Fluorine-Lined Diaphragm Valve |

|---|---|---|

| Initial Cost | Low | High |

| Service Life | 3-6 months | 3-5 years |

| Replacement Frequency | Extremely High (10-20 times in 5 years) | Very Low (0-1 valve body[^3] in 5 years) |

| Maintenance | Frequent, complex (seals, body) | Simple, periodic (diaphragm only) |

| Total 5-Year Cost | Very High | 40-60% Lower |

As you can see, the initial savings from a cheaper valve are quickly erased by the endless cycle of replacement and maintenance. The fluorine-lined valve is a far more stable and predictable investment.

What Should You Check Before Installing and Operating These Valves?

You've bought the right valve, but improper installation or operation can ruin it. How do you ensure it performs well for its full service life?

For installation, use a torque wrench on flange bolts to avoid cracking the lining. For maintenance, monitor the diaphragm and replace it every 6-12 months if you see flow issues. Also, never run an empty valve under high pressure, as it damages the diaphragm.

Getting the most out of these high-performance valves comes down to a few simple but critical practices. I learned these lessons over time, some of them the hard way. Here is what you need to know.

First, be careful during installation. The fluorine lining is strong, but it can be damaged by excessive force. When you tighten the flange bolts, do not just use a standard wrench and tighten them as hard as you can. This can put too much stress on the lining and cause it to crack. You must use a torque wrench and tighten the bolts to the manufacturer's specified torque value. This small step is crucial for preventing damage that could lead to premature failure.

Second, focus on smart maintenance. Your primary maintenance task will be monitoring the diaphragm. If you notice that the flow through the valve has become unstable or you see signs of a very minor leak, it is almost certainly the diaphragm reaching the end of its life. The solution is simple: just replace the diaphragm. I recommend scheduling a replacement every 6 to 12 months, though you may need to adjust this based on how corrosive your media is.

Finally, practice proper operation. One key tip is to avoid operating the valve when the pipeline is empty and under high gas pressure. This can cause the diaphragm to be forced shut too aggressively, which accelerates wear and tear. When shutting down the system, it is a good habit to close the upstream and downstream gate valves and release any trapped pressure to protect the diaphragm.

Conclusion

In wastewater treatment[^4], fluorine-lined diaphragm valves are not a luxury. They are a smart, long-term investment for reliable, leak-free, and cost-effective corrosion control.

[^1]: Explore the advantages of these valves for corrosion control and reliability in wastewater treatment. [^2]: Discover best practices for managing corrosive wastewater and preventing valve failures. [^3]: Learn about the critical functions of the valve body in ensuring performance and durability. [^4]: Discover essential practices for efficient and safe wastewater treatment operations. [^5]: Explore the features and benefits of pneumatic diaphragm valves in wastewater applications.