Struggling with contamination in your pharma production? A single impure batch can be costly and dangerous. Diaphragm valves provide the sterile, reliable fluid control you need to ensure product purity.

Diaphragm valves are essential in the pharmaceutical industry because their unique design ensures a sterile fluid path[^1]. They prevent contamination, minimize product loss, and are ideal for Clean-in-Place (CIP) and Sterilize-in-Place (SIP)[^2] processes. This makes them perfect for handling sensitive and high-purity fluids.

You've seen the quick answer, but the details are what really matter for your operations. The design of these valves is what makes them so special for pharma applications. Let's break down exactly how they meet the strict demands of this industry and why they are the go-to choice for so many of our clients.

How Do Diaphragm Valves Maintain a Sterile Environment?

Worried about cross-contamination[^3] between batches? It's a risk that can shut down production. The unique design of a diaphragm valve isolates the fluid, ensuring absolute purity every time.

Diaphragm valves maintain sterility by using a flexible diaphragm to completely isolate the process fluid from the valve's operating mechanism. This crevice-free, smooth internal surface prevents bacterial growth and makes the valve easy to clean, ensuring a consistently sterile environment for sensitive products.

The ability to maintain a sterile fluid path is the number one reason diaphragm valves are so common in pharmaceutical manufacturing. It all comes down to their internal design. Unlike other valve types, a diaphragm valve has no hidden pockets or crevices where bacteria or product residue can get trapped.

The Core of Hygienic Design

The key feature is the diaphragm itself. It's a flexible membrane that separates the fluid from all the moving parts of the valve, like the stem and actuator. This means there is zero chance for lubricants or outside contaminants to enter the process stream. The body of the valve is designed to be smooth and self-draining. This "low dead-leg" design ensures that after a process is complete, the valve can be fully drained and cleaned, leaving no residue behind. This is critical for preventing the growth of biofilms and ensuring product purity from one batch to the next.

Material Selection is Key

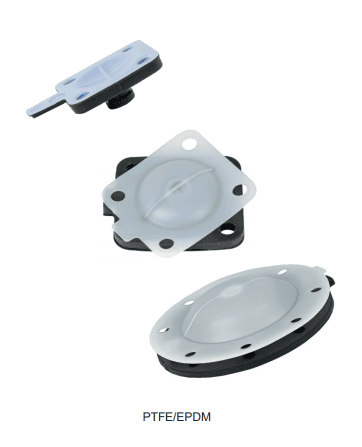

The materials used are just as important. For our pharmaceutical clients, we often recommend valves with plastic linings like PTFE[^4]. These materials are incredibly non-reactive and have a very smooth surface, which further reduces the risk of anything sticking to them. They also meet strict industry standards, such as being FDA-compliant.

| Feature | Diaphragm Valve | Ball Valve |

|---|---|---|

| Internal Cavities | None (smooth, crevice-free) | Yes (around the ball) |

| Contamination Risk | Very Low | High |

| Cleanability (CIP/SIP) | Excellent | Poor |

| Fluid Isolation | Complete | Partial (stem packing can leak) |

What Makes Diaphragm Valves Ideal for CIP and SIP Processes?

Finding valve cleaning and sterilization to be a major bottleneck? Manual processes are slow and unreliable. Diaphragm valves are built for automated CIP and SIP systems[^5], ensuring fast, effective cleaning.

Diaphragm valves excel in CIP and SIP because their smooth, pocket-less interior allows cleaning fluids and steam to reach all surfaces effectively. The tight, leak-proof seal ensures that high temperatures and aggressive chemicals are contained, guaranteeing a thorough and repeatable sterilization process.

Clean-in-Place (CIP) and Sterilize-in-Place (SIP)[^2] are automated processes that are fundamental to modern pharmaceutical production. They allow for the entire system to be cleaned and sterilized without being taken apart. Diaphragm valves are perfectly suited for this. Their design isn't just about preventing contamination during production; it's also about making cleaning as effective as possible.

The Mechanics of Effective Cleaning

During a CIP cycle, powerful cleaning agents like caustic soda or acids are flushed through the system. The smooth, unobstructed flow path of a diaphragm valve ensures these chemicals make contact with every single surface. There are no dead spots where old product can hide. The valve opens fully to allow for high-velocity flow, which helps scrub the internal surfaces clean. When the valve closes, it provides a tight seal, allowing different parts of the system to be isolated and cleaned in sequence.

Sealing Under Extreme Conditions

SIP processes are even more demanding. They use high-temperature steam, often above 121°C (250°F), to kill any remaining microorganisms. The diaphragm material must be able to handle these temperatures and pressures without failing. This is why we work closely with our clients to select the right diaphragm material, such as EPDM or PTFE, which are specifically designed to withstand repeated sterilization cycles without degrading. The valve's robust construction ensures it remains leak-tight, which is crucial for both safety and the effectiveness of the sterilization.

Why is Precise Control Crucial for Handling Active Pharmaceutical Ingredients?

Struggling with precise dosing of valuable APIs? Even small errors can be incredibly costly. Diaphragm valves offer the fine control needed to ensure accurate mixing and formulation every time.

Precise control is vital for APIs to ensure correct dosage and product efficacy. Diaphragm valves provide excellent throttling capabilities for accurate metering. Their gentle, non-shearing action also protects sensitive biological products, like vaccines and proteins, from damage during processing.

Active Pharmaceutical Ingredients (APIs) are the most valuable and sensitive components of any drug. Getting the dosage exactly right is not just a matter of quality; it's a matter of patient safety. This is where the precise control of a diaphragm valve becomes an indispensable tool. It allows for the accurate and repeatable dosing required for modern medicine.

Throttling and Dosing

The "weir-type" diaphragm valve design is particularly good for flow control. As you turn the handle, the flow increases in a very predictable and linear way. This makes it easy for operators or automated systems to dial in the exact flow rate needed for dosing or mixing. This level of precision minimizes waste of expensive APIs and ensures that every batch meets the exact formulation specifications. I remember a client who switched to our pneumatic diaphragm valves for their automated dosing system. They saw a significant improvement in batch consistency and a measurable reduction in product loss, which directly impacted their bottom line.

Protecting Sensitive Media

Many modern drugs, especially biologics like vaccines and cell therapies, are made of large, complex molecules that are very fragile. High shear forces, like those created by the fast-closing action of a ball or butterfly valve, can literally tear these molecules apart, rendering the drug ineffective. Diaphragm valves are different. They provide a gentle, non-shearing closure. The diaphragm slowly presses down on the weir, gently stopping the flow without creating turbulence. This protects the integrity of the product, which is absolutely critical for these advanced and life-saving medicines.

Conclusion

In summary, diaphragm valves are critical for the pharmaceutical industry. Their hygienic design, cleanability, and precise control ensure the safety, purity, and quality of modern medicines. They are truly essential.

[^1]: Understanding the sterile fluid path is crucial for ensuring product purity in pharmaceutical manufacturing. [^2]: Learning about SIP processes can enhance sterilization efficiency, ensuring product safety and compliance. [^3]: Preventing cross-contamination is vital for maintaining batch integrity and avoiding costly production shutdowns. [^4]: PTFE linings offer non-reactive surfaces, reducing contamination risks and meeting strict industry standards. [^5]: Automated systems enhance cleaning efficiency, reducing manual labor and ensuring thorough sterilization.