NO NO 1

During winter construction, water pressure test is carried out under negative temperature.

Consequences: due to the rapid freezing in the tube during the hydraulic test, the tube was frozen

Measures: Try to conduct a water pressure test before the winter application, and blow off the water after the pressure test, especially the water in the valve must be cleaned, otherwise the valve will rust or freeze.

When the water pressure test is carried out in the winter, the project must be carried out at a positive indoor temperature, and the water must be blown off after the pressure test.

NO NO 2

The pipeline system was not flushed carefully before completion, and the flow rate and speed did not meet the pipeline flushing requirements. It even replaces flushing with water pressure strength test.

Consequences: The water quality does not meet the operating requirements of the pipeline system, which often results in the reduction or blockage of the pipeline cross-section.

Measures: Use the maximum design flow rate in the system or a water flow velocity that should not be less than 3m/s for flushing. The water color and transparency of the discharge outlet should be consistent with the water color and transparency of the inlet water visually as qualified.

NO NO 3

Sewage, rainwater, and condensate pipes are concealed without closing the water test.

Consequences: It may cause water leakage and cause user losses.

Measures: The closed-water test work should be checked and accepted in strict accordance with the specifications. Sewage, rainwater, condensate pipes, etc. buried underground, suspended ceilings, pipe rooms, etc. must be ensured not to leak.

NO NO 4

In the hydraulic strength test and tightness test of the piping system, only the pressure value and water level change are observed, and the leakage check is not enough.

Consequences: Leakage occurs after the pipeline system is in operation, affecting normal use.

Measures: When the piping system is tested in accordance with the design requirements and construction specifications, in addition to recording the pressure value or water level change within the specified time, it is particularly necessary to carefully check whether there is a leakage problem.

NO NO 5

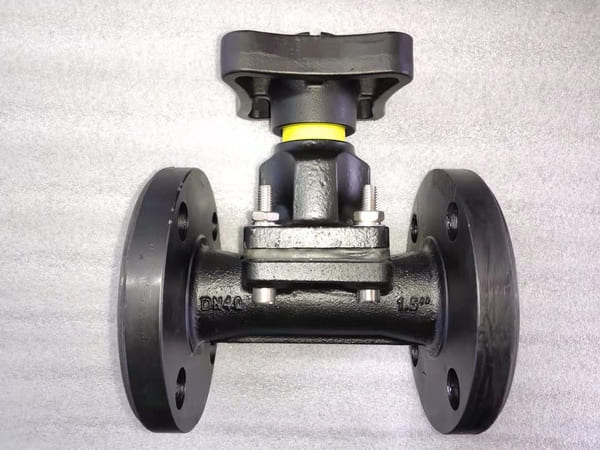

Ordinary valve flanges are used for butterfly valve flanges.

Consequences: The size of the butterfly valve flange is different from that of the ordinary valve flange. Some flanges have a small inner diameter, while the butterfly valve has a large disc, which causes the valve to fail to open or hard to open and damage the valve.

Measures: The flange should be processed according to the actual size of the butterfly valve flange.

NO NO 6

During the construction of the building structure, no holes and embedded parts are reserved, or the size of the reserved holes is too small and the embedded parts are not marked.

Consequences: During the construction of the heating and sanitation project, the building structure was cut, and even the stressed steel bars were cut off, affecting the safety performance of the building.

Measures: Be familiar with the construction drawings of the heating and sanitation engineering. According to the needs of the installation of pipelines and supports, actively cooperate with the construction of the building structure to reserve holes and embedded parts, and refer to the design requirements and construction specifications.

NO NO 7

When welding the pipeline, the pipe is not on the same centerline after the aligning, and there is no gap between the aligning, and the thick-walled pipe is not beveled. The width and height of the welding seam do not meet the requirements of the construction specification.

Consequences: The misalignment of the pipe does not directly affect the quality of welding and the quality of perception. There is no gap in the matching, and the thick-walled pipe does not shovel the bevel. When the width and height of the welding seam do not meet the requirements, the welding cannot meet the requirements of strength.

Measures: After welding the pipes, the pipes should not be misaligned, but should be on a center line; gaps should be left for the counterparts; thick-walled pipes should be beveled. In addition, the width and height of the weld shall be welded in accordance with the requirements of the specification.

NO NO 8

The pipeline is directly buried in frozen soil and untreated loose soil, and the spacing and location of the pipeline support piers are improper, even in the form of stacking bricks.

Consequences: The pipeline suffered damage during the process of backfilling and tamping due to unstable support, resulting in rework and repair.

Measures: The pipeline shall not be buried in frozen soil and untreated loose soil. The spacing of the buttresses must meet the requirements of the construction specification, and the support pads must be firm, especially the pipe joints, and should not bear shearing force. Brick buttresses should be built with cement mortar to ensure completeness and firmness.

NO NO 9

The material of the expansion bolts for fixing the pipe bracket is poor, the hole diameter of the expansion bolts is too large, or the expansion bolts are installed on the brick wall or even the lightweight wall.

Consequences: The pipe support is loose, the pipe is deformed, or even falls off.

Measures: Expansion bolts must be qualified products. If necessary, samples should be tested and checked. The hole diameter of the expansion bolts should not be larger than the outer diameter of the expansion bolts by 2mm. Expansion bolts should be applied to the concrete structure.

NO NO 10

The flanges and gaskets of the pipe connection are not strong enough, and the connecting bolts are short or have a small diameter. Heat pipes use rubber pads, cold water pipes use double-layer pads or inclined pads, and flange gaskets protrude into the pipes.

Consequences: The flange connection is not tight, or even damaged, and leakage occurs. The flange gasket protruding into the pipe will increase the water flow resistance

Measures: Pipe flanges and gaskets must meet the requirements of pipeline design working pressure.

The flange gaskets of heating and hot water supply pipes should be rubber asbestos gaskets; the flange gaskets of water supply and drainage pipes should be rubber gaskets.

The gasket of the flange shall not protrude into the pipe, and its outer circle should reach the bolt hole of the flange. No bevel pads or several gaskets should be placed in the middle of the flange. The diameter of the bolts of the connecting flange should be less than 2mm than the diameter of the flange. The length of the bolt rod and the nut should be 1/2 of the thickness of the nut.

NO NO 11

The valve installation method is wrong.

For example, the water (vapor) flow direction of the globe valve or check valve is opposite to the sign, the valve stem is installed downwards, the horizontally installed check valve is installed vertically, the rising-stem gate valve or butterfly valve handle has no open or closed space, and the valve stem is concealed. Do not face the inspection door.

Consequences: The valve fails, the switch is difficult to repair, and the valve stem faces down often causing water leakage.

Measures: Strictly install according to the valve installation instructions. For the rising stem gate valve, leave enough stem to extend the opening height. The butterfly valve fully considers the handle rotation space. Various valve stems cannot be lower than the horizontal position, let alone downward. The concealed valve should not only be equipped with an inspection door that meets the needs of valve opening and closing, but also the valve stem should face the inspection door.

NO NO 12

The specifications and models of the installed valve do not meet the design requirements

For example, the nominal pressure of the valve is less than the system test pressure; the water supply branch pipe adopts a gate valve when the pipe diameter is less than or equal to 50mm; the dry and stand pipe of the hot water heating adopts a globe valve; the fire water pump suction pipe adopts a butterfly valve.

Consequences: Affect the normal opening and closing of the valve and the adjustment of resistance, pressure and other functions. Even during the operation of the system, the valve is damaged and forced to be repaired.

Measures: Familiarize with the application range of various valves, and select valve specifications and models according to design requirements. The nominal pressure of the valve must meet the requirements of the system test pressure. According to the requirements of the construction specification: the water supply branch pipe diameter is less than or equal to 50mm should use a globe valve; when the pipe diameter is greater than 50mm, a gate valve should be used. Gate valves should be used for hot water heating dry and vertical control valves, and butterfly valves should not be used for fire-fighting water pump suction pipes.

NO NO 13

Do not perform necessary quality inspections as required before valve installation.

Consequences: In the system operation, the valve switch is not flexible, the closing is not tight, and the water (steam) leakage occurs, causing rework and repair, and even affecting the normal water supply (steam).

Measures: Before the valve is installed, the pressure strength and tightness test should be done. In the test, 10% of the quantity of each batch (same brand, same specification, and same model) shall be randomly checked, and no less than one.

For closed-circuit valves installed on the main pipe to cut off, the strength and tightness tests should be done one by one. The valve strength and tightness test pressure should meet the requirements of “Code for Construction Quality Acceptance of Building Water Supply and Drainage and Heating Engineering” (GB 50242-2002).

NO NO 14

The main materials, equipment and products used in construction lack technical quality appraisal documents or product qualification certificates that meet the current national or ministerial standards.

Consequences: The quality of the project is unqualified, there are hidden dangers of accidents, it cannot be delivered on time, and must be reworked and repaired; it causes delays in the construction period and increases the input of labor and materials.

Measures: The main materials, equipment and products used in water supply and drainage and heating and sanitation projects should have technical quality appraisal documents or product qualification certificates that meet the current standards issued by the state or ministry; their product names, models, specifications, and national quality standards should be indicated Code name, date of manufacture, name and location of manufacturer, inspection certificate or code number of manufactured product.

NO NO 15

Valve inverted installation

Consequences: Check valves, throttle valves, pressure reducing valves, check valves and other valves are all directional. If they are installed upside down, the throttle valve will affect the use effect and life; the pressure reducing valve does not work at all, the check valve can even cause danger.

Measures: Normal valves have direction signs on the valve body; if not, they should be correctly identified according to the working principle of the valve. The valve cavity of the globe valve is asymmetrical left and right. The fluid should pass through the valve port from bottom to top, so that the fluid resistance is small (determined by the shape), and the opening is labor-saving (because the medium pressure is upward). . This is the reason why the globe valve cannot be reversed installed.

Do not install the gate valve upside down (that is, the handwheel is down), otherwise the medium will remain in the valve cover space for a long time, which will easily corrode the valve stem, and it is contraindicated by certain process requirements. At the same time, it is extremely inconvenient to replace the packing.

The exposed stem gate valve should not be installed underground, otherwise the exposed stem will be corroded due to moisture.

When installing the lift check valve, make sure that its valve flap is vertical, so that it can be lifted and moved flexibly.

For the swing check valve, ensure that its pin shaft is in the horizontal direction during installation, so that it can swing flexibly.

The pressure reducing valve should be installed upright on a horizontal pipe, and should not be tilted in all directions.

NO NO 16

Manual valve opening and closing, too much force

Consequences: if the consequences are light, the valve is damaged, and if the consequences are serious, it will lead to a safety accident.

Measures: Manual valve, its hand wheel or handle is designed according to ordinary manpower, taking into account the strength of the sealing surface and the necessary closing force. Therefore, you cannot use a long lever or a long wrench to move. Some people are accustomed to using wrenches, and they should be careful not to use too much force, otherwise it will easily damage the sealing surface, or break the handwheel and handle. When opening and closing the valve, the force should be steady without impact. Some parts of high-pressure valves with impact opening and closing have considered that this impact force cannot be equal to ordinary valves. For the steam valve, before opening, it should be pre-heated and the condensed water should be removed. When opening, it should be as slow as possible to avoid water hammer. When the valve is fully opened, the handwheel should be turned upside down a little to tighten the threads to avoid loosening and damage. For rising stem valves, remember the valve stem positions when fully open and fully closed to avoid hitting the top dead center when fully open. And it is convenient to check whether it is normal when fully closed. If the valve stem falls off, or large debris is embedded between the valve core seal, the position of the valve stem will change when it is fully closed. When the pipeline is first used, there are a lot of internal dirt. You can open the valve slightly, use the high-speed flow of the medium to wash it away, and then close it gently (not fast or abruptly to prevent residual impurities from pinching the sealing surface). Turn it on again, repeat this many times, flush out the dirt, and then put it back into normal work. For normally open valves, there may be dirt on the sealing surface. When it is closed, use the above-mentioned methods to flush it out, and then formally close it tightly. If the handwheel and handle are damaged or lost, they should be provided immediately and cannot be replaced with a flexible wrench to avoid damage to the valve stem and failure of opening and closing, resulting in accidents during production. Some medium cools down after the valve is closed, causing the valve to shrink. The operator should close it again at an appropriate time so that the sealing surface does not leave any crevices. Otherwise, the medium will flow through the crevices at a high speed and it will easily erode the sealing surface. . During operation, if the operation is found to be too laborious, the reason should be analyzed. If the packing is too tight, it can be properly loosened. If the valve stem is skewed, the personnel should be notified to repair it. When some valves are closed, the closing part is heated and expands, which makes it difficult to open; if it must be opened at this time, the valve cover can be loosened half a turn to one turn to eliminate the stress on the valve stem, and then the handwheel is activated.

NO NO 17

Improper installation of valves in high temperature environment

Consequence: cause a leak

Measures: The high temperature valve above 200℃ is at normal temperature when installed, and after normal use, the temperature rises, the bolt is heated and expands, and the gap increases, so it must be tightened again, which is called “thermal tightening”. The operator should pay attention to this work. , Otherwise it is easy to leak.

NO NO 18

Not timely drainage in cold weather

Measures: When the weather is cold, if the water valve is closed for a long time, the accumulated water behind the valve should be removed. After the steam valve stops, the condensed water should also be removed. The bottom of the valve is like a plug, which can be opened to drain.

NO NO 19

Non-metal valve, opening and closing force is too large

Measures: When the new valve is used, the packing should not be too tight, so as not to leak, so as to avoid too much pressure on the valve stem, accelerating wear, and strenuous opening and closing. The quality of valve installation directly affects the use, so careful attention must be paid to the direction and position of the valve, valve construction operations, valve protection facilities, bypass and instrumentation, and valve packing replacement.

NO NO 20

No operating space at the installation location

Measures: The location of the valve installation must be convenient for operation; even if the installation is temporarily difficult, it is necessary to consider the long-term work of the operator. It is best to keep the valve handwheel flush with the chest (usually 1.2 meters away from the operating floor), so that it is easier to open and close the valve. The handwheel of the floor valve should be upwards, do not tilt, so as to avoid awkward operation. The valve of the wall machine and the equipment should also leave room for the operator to stand. It is necessary to avoid operating from the sky, especially acid and alkali, toxic media, etc., otherwise it is very unsafe.

NO NO 21

Impact valves made of brittle materials

Measures: Be careful during installation and construction, and avoid hitting valves made of brittle materials. Before installation, check the valve, check the specifications and models, and identify whether there is any damage, especially the valve stem. Rotate it a few times to see if it is skewed, because the valve stem is most likely to be skewed during transportation. Also remove the debris in the valve. When the valve is hoisted, the rope should not be tied to the handwheel or valve stem to avoid damaging these parts. It should be tied to the flange. The pipeline connected to the valve must be cleaned. Compressed air can be used to blow away iron oxide filings, mud sand, welding slag and other debris. These debris are not only easy to scratch the sealing surface of the valve, the large particles of debris (such as welding slag) can also block the small valve and make it invalid. When installing the screw valve, the sealing packing (line hemp plus lead oil or PTFE tape) should be wrapped on the pipe thread, and do not get into the valve, so as to avoid the accumulation of the valve and affect the flow of the medium. When installing the flange valve, pay attention to tighten the bolts symmetrically and evenly. The valve flange and pipe flange must be parallel with reasonable clearance to avoid excessive pressure or even cracking of the valve. Special attention should be paid to valves with brittle materials and low strength. Valves that need to be welded to the pipe should be spot welded first, then the closing part should be fully opened, and then welded to death.

NO NO 22

The valve has not been insulated and cold-preserved

Measures: Some valves must also have external protection facilities, which are heat preservation and cold preservation. Sometimes heat tracing steam pipelines are added in the insulation layer. What kind of valve should be kept warm or cold depends on the production requirements. In principle, if the medium in the valve reduces the temperature too much, it will affect the production efficiency or freeze the valve, it needs to be kept warm, or even heat; where the valve is exposed, which is unfavorable to production or causes frosting and other undesirable phenomena, it needs to be kept cold. Thermal insulation materials include asbestos, slag wool, glass wool, perlite, diatomaceous earth, vermiculite, etc.; cold insulation materials include cork, perlite, foam, plastics, etc.

NO NO 23

Packing is not replaced regularly

Measures: Inventory valves, some packing is not good enough, and some are not in line with the used medium, which requires replacement of packing.

The valve faces thousands of different media. The stuffing box is always filled with ordinary packing, but when using it, the packing must be compatible with the medium.

When replacing the packing, press it in circle by circle. The seam of each circle should be 45 degrees, and the seams of the circle and circle should be staggered by 180 degrees. The height of the packing should consider the room for the gland to continue to be compacted. At present, the packing chamber at the lower part of the gland should be at an appropriate depth. This depth can generally be 10-20% of the total depth of the packing chamber.

For higher demanding valves, the seam angle is 30 degrees. The seams between the circles are staggered by 120 degrees.

In addition to the above fillers, three rubber O-rings (natural rubber resistant to weak alkalis below 60 degrees Celsius, butadiene nitrile rubber resistant to oils below 80 degrees Celsius, and fluorine rubber resistant to various corrosive media below 150 degrees Celsius) can also be used according to specific conditions. Stacked polytetrafluoroethylene ring (resistant to strong corrosive media below 200 degrees Celsius) and nylon bowl-shaped ring (resistant to ammonia and alkali below 120 degrees Celsius) and other forming fillers. Outside the ordinary asbestos packing, a layer of PTFE raw material tape can improve the sealing effect and reduce the electrochemical corrosion of the valve stem.

When compacting the packing, rotate the valve stem at the same time to keep the surrounding uniform and prevent it from being too dead. Tighten the gland with even force and not tilt.