Struggling to pick the right diaphragm valve? The wrong material can cause leaks and costly failures. I'll guide you through the common materials to ensure your system's reliability.

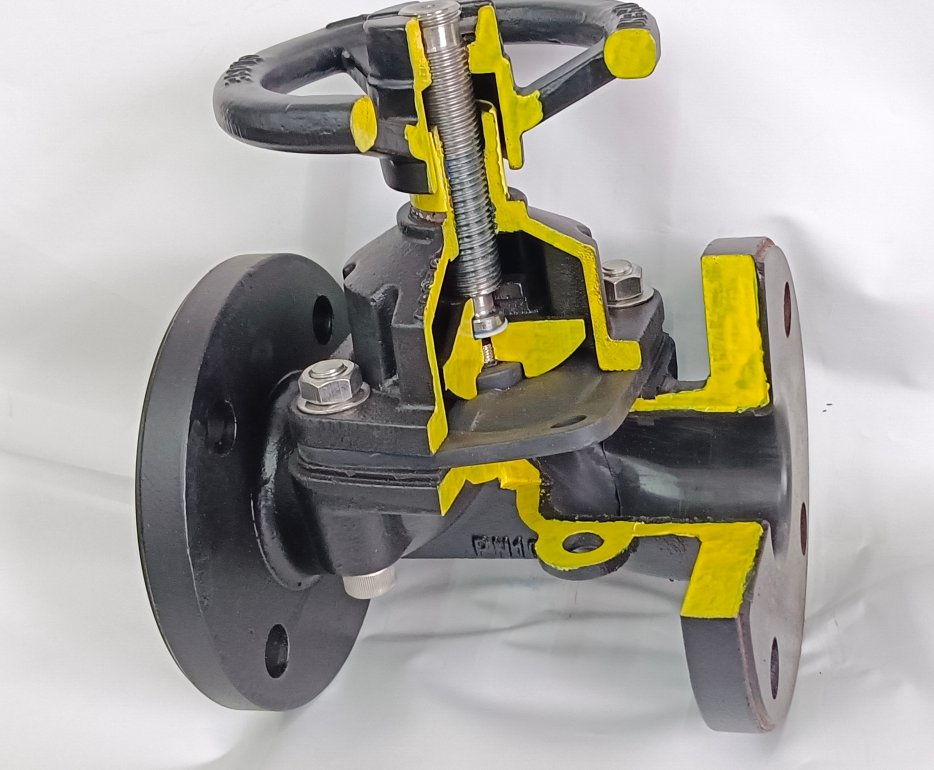

Diaphragm valves use various materials to suit different jobs. Valve bodies are often cast iron[^1], ductile iron[^2], or stainless steel[^3], while diaphragms are made from flexible materials like EPDM[^4] or PTFE[^5]. This combination ensures durability and chemical resistance for specific industrial applications.

Over the years, I've seen how a simple material choice can make or break a project. It’s not just about what works, but what works best for your specific conditions. A valve is a system of parts, and each part needs the right material to do its job. Let's break down these materials piece by piece, starting with the foundation of the valve: the body.

Which Material Is Best for Your Diaphragm Valve Body?

Choosing a valve body material feels overwhelming. A poor choice leads to corrosion and catastrophic failure. I'll help you compare common options to find the most reliable and cost-effective solution.

For general water or chemical use, cast iron[^1] (CI) and ductile iron[^2] (DI) offer great value. For high corrosion resistance, stainless steel[^3] is the standard. Plastics like PVC[^6] or PVDF are excellent for specific low-pressure, corrosive applications, but can't handle high stress.

The valve body is the main housing that contains the fluid. It has to be strong and compatible with whatever you're running through your pipes. In my factory, we specialize in cast iron[^1] and ductile iron[^2] bodies because they offer a fantastic balance of performance and cost for many industrial uses, especially in chemical and power plants.

Metal Bodies

Metals are the workhorses of the valve world. They provide strength and can handle pressure and temperature swings. We use a resin-coated sand casting[^7] process for our CI and DI bodies, which results in a much smoother surface and fewer imperfections. This is something our clients, especially those with their own brands, really appreciate.

Plastic Bodies

Plastics are light and offer amazing resistance to specific chemicals, but they generally can't take the heat or pressure that metals can. They are great for low-pressure systems where corrosion is the main enemy.

Here is a simple breakdown:

| Material | Key Advantage | Common Application |

|---|---|---|

| Cast Iron (CI) | Cost-effective and strong | Water, air, general chemicals |

| Ductile Iron (DI) | Higher strength, better for impact | High-stress systems, wastewater |

| Stainless Steel | Excellent corrosion resistance | Food, pharma, highly corrosive media |

| PVC / CPVC | Lightweight and affordable | Low-pressure water treatment |

| PVDF / PP | Superior chemical resistance | Aggressive chemical lines |

How Do You Choose the Right Diaphragm Material?

A failed diaphragm can stop your entire operation. It's the part that flexes and seals, so its material is critical. Let's find the most durable and compatible diaphragm for your fluid.

EPDM[^4] is a great all-rounder for acids, alkalis, and hot water. For highly corrosive chemicals, PTFE[^5] offers unbeatable resistance. Buna-N[^8] is perfect for oils, while Butyl rubber[^9] is excellent for gases and steam sterilization applications. The choice depends entirely on the fluid.

The diaphragm is the heart of the valve. It's the flexible membrane that isolates the fluid from the valve's moving parts and controls the flow. A diaphragm failure isn't just a leak; it's a complete shutdown. That's why we offer a wide range of rubber and plastic linings and diaphragms. We use a mechanical application process for our linings, which creates a seamless, smooth surface without the risk of delamination you might see with other methods. This small detail makes a huge difference in the valve's lifespan.

Common Diaphragm Elastomers

Each material has its own strengths and weaknesses when it comes to chemical compatibility and temperature.

- EPDM[^4]: This is a very popular choice. It handles a wide range of chemicals, especially acids and alkalis, and is great with hot water.

- PTFE[^5]: When you're dealing with very aggressive or corrosive fluids, PTFE[^5] is the king. It’s almost completely chemically inert.

- Buna-N[^8] (Nitrile): If you're working with oils, fuels, or petroleum-based liquids, Buna-N[^8] is your best bet.

- Butyl: This material has very low gas permeability, making it perfect for applications involving gases or for steam sterilization.

Here’s a quick reference table:

| Material | Best For | Avoid |

|---|---|---|

| EPDM[^4] | Water, Steam, Acids, Alkalis | Oils, Solvents |

| PTFE[^5] | Aggressive Chemicals, Solvents | Abrasive Slurries (unless backed) |

| Buna-N[^8] | Oils, Petroleum, Fuels | Strong Acids, Ozone |

| Butyl | Gases, Steam, Ketones | Petroleum, Solvents |

What About the Stem and Bonnet Materials?

Don't forget the valve's support structure. A weak stem or bonnet can compromise the entire valve's operation. Let’s quickly cover the standard materials that ensure long-term reliability.

Stainless steel is the most common choice for stems and bonnets because of its strength and excellent corrosion resistance. For less demanding, lighter-duty applications, brass is sometimes used as a cost-effective alternative that still resists corrosion.

The bonnet is the cover that protects the valve's internal operating mechanism, and the stem connects the handwheel or actuator to the diaphragm. I've seen clients try to save a few dollars here, only to have a valve seize up because the stem corroded. It's a classic case of being penny-wise and pound-foolish. A valve you can't operate is a useless piece of metal.

Why Material Choice Matters Here

- Strength: The stem needs to withstand the force of opening and closing the valve thousands of times without bending or breaking.

- Corrosion Resistance: Even though the stem and bonnet are isolated from the main fluid by the diaphragm, they are still exposed to the external environment. In a chemical plant or a coastal facility, atmospheric corrosion is a real threat.

That's why we, and most reputable manufacturers, standardize on stainless steel. It provides the necessary strength and holds up incredibly well in almost any industrial environment. Brass is an option, but we generally recommend sticking with stainless steel for any serious industrial application. It’s a small part of the total cost but has a huge impact on the valve's long-term reliability and safety.

Conclusion

Choosing the right materials for the body, diaphragm, and stem is key to a diaphragm valve's performance. Matching them to your application ensures safety, reliability, and long service life.

[^1]: Learn why cast iron is a popular choice for valve bodies, offering a balance of cost and performance for various industrial applications. [^2]: Discover the advantages of ductile iron in high-stress systems, providing strength and impact resistance for demanding environments. [^3]: Explore the reasons stainless steel is the standard for corrosion resistance, especially in food, pharma, and corrosive media applications. [^4]: Learn about EPDM's versatility in handling acids, alkalis, and hot water, making it a reliable choice for various industrial fluids. [^5]: Understand why PTFE is favored for its chemical inertness, providing unmatched resistance to aggressive and corrosive fluids. [^6]: Find out how PVC is used in valve bodies for low-pressure, corrosive applications, offering affordability and chemical resistance. [^7]: Learn about the resin-coated sand casting process, which results in smoother surfaces and fewer imperfections in valve bodies. [^8]: Discover why Buna-N is ideal for applications involving oils, fuels, and petroleum-based liquids, offering excellent compatibility. [^9]: Explore the properties of Butyl rubber that make it suitable for gases and steam sterilization, with low gas permeability.