Struggling with valves that wear out too fast in abrasive conditions? This frequent replacement downtime hurts your operation. Rubber-lined diaphragm valves offer a durable, cost-effective solution for these demanding environments.

A rubber-lined diaphragm valve is the ideal choice for durability and handling abrasive media like slurries and moderate chemicals. Its superior abrasion resistance, reliable sealing, and cost-effectiveness make it a top performer in industries requiring dependable control under medium-duty corrosive and abrasive conditions.

Now that you have a basic idea, you might be wondering what specific features give these valves their strength. Getting into the details is crucial for making sure you're choosing the right valve for your system. Let's dig deeper to see what really sets them apart and where they perform best.

What Key Features Make These Valves So Durable?

Choosing a valve without understanding its core features is a gamble. You risk selecting a valve that fails prematurely, causing unexpected shutdowns and maintenance headaches that disrupt your entire process.

The durability of these valves comes from their robust rubber lining for wear resistance, an isolated mechanism for a perfect leak-proof seal, and a streamlined flow path that prevents clogs. These features work together to ensure a long service life with minimal maintenance.

I've been in this business for years, and the design of these valves still impresses me. The real magic is in how a few simple, robust features combine to create a nearly indestructible valve for specific applications. Let's break down what makes them so tough.

The Power of the Rubber Lining

The first line of defense is the thick rubber lining. This isn't just any rubber; it's specifically chosen for the job. We offer various types, like EPDM[^1] for water treatment[^2] chemicals, NBR[^3] for oils and fuels, and natural rubber[^4] for high-abrasion slurries. At our factory, we use a mechanical application process. This ensures the lining is completely seamless and smooth, unlike some older methods that can leave weak spots. This superior finish not only looks better but also provides a more uniform barrier against corrosive and abrasive media, which directly translates to a longer lifespan for the valve.

The Leak-Proof Sealing Mechanism

The core design principle of a diaphragm valve is isolation. The flexible rubber diaphragm completely separates the fluid from the valve's operating mechanism—the bonnet, stem, and handwheel. This means no corrosive or gritty material ever reaches the moving parts. This is a huge advantage. It eliminates the most common cause of failure in other valve types and prevents any potential leakage to the outside environment. This makes the valve incredibly reliable and safe, especially when handling materials you don't want escaping.

Streamlined for Abrasives

Most of our rubber-lined valves use a weir-style body[^5]. This design features a raised "weir" or dam in the middle of the valve. The diaphragm presses down onto this weir to create a tight seal. The flow path over the weir is smooth and contoured, which prevents abrasive particles in slurries from settling and causing blockages or excessive wear. This streamlined design ensures that media flows through smoothly, minimizing turbulence and extending the life of both the lining and the diaphragm itself.

| Lining Material | Key Strengths | Common Applications |

|---|---|---|

| EPDM[^1] | Excellent resistance to water, steam, acids, alkalis | Water Treatment, Chemical Dosing, Power Plants |

| NBR[^3] (Buna-N) | Superior resistance to oils, fuels, solvents | Petrochemical, Industrial Wastewater |

| Natural Rubber | Highest abrasion resistance[^6], great flexibility | Mining Slurries, Sand & Gravel, Ash Handling |

| Butyl | Low gas permeability, good chemical resistance[^7] | Gas applications, certain chemical processes |

Where Do Rubber-Lined Diaphragm Valves Truly Excel?

Are you unsure if a rubber-lined valve is the right fit for your specific industry? Making the wrong choice can lead to inefficient processes, frequent maintenance, and costly operational failures.

Rubber-lined diaphragm valves are the workhorses in industries like mining, water treatment, and chemical processing. They excel at handling abrasive slurries, sludges, and moderately corrosive chemicals where both durability and cost-effectiveness are critical for success.

I remember talking with a procurement manager from a mining company. He was replacing ball valves in a slurry line every three months. The abrasive particles were just tearing the seats apart. We switched him to our natural rubber[^4] rubber-lined diaphragm valves[^8], and he called me a year later to say they were still running perfectly. That’s the kind of problem these valves are built to solve. Let's look at their prime application areas.

Mining and Mineral Processing

This is where rubber-lined valves shine. The process of extracting minerals involves moving massive amounts of abrasive ore slurries. Standard valves get destroyed quickly. Our valves, with thick natural rubber[^4] linings, are designed for exactly this. The rubber is resilient enough to absorb the impact of sharp particles without tearing. The valve bodies, made from durable ductile iron (DI) or cast iron (CI) using a resin-coated sand process, provide the structural strength needed in these rugged environments. They are the go-to solution for slurry transport, flotation agent control, and tailing lines.

Water and Wastewater Treatment

Wastewater plants are complex environments with a mix of solids, sludges, and treatment chemicals. Rubber-lined diaphragm valves are perfect here. EPDM[^1]-lined valves are excellent for dosing systems, handling chemicals like sodium hypochlorite, coagulants, and pH-adjusting acids or alkalis. The leak-proof seal prevents dangerous chemical spills and waste. For sludge lines, the smooth flow path prevents clogging. We offer both manual valves for simple shut-off and pneumatic valves[^9] that can be integrated into automated plant control systems, giving operators the flexibility they need.

Chemical and Power Plants

In large-scale chemical and power generation facilities, cost and reliability are key. While highly aggressive chemicals might require PTFE linings, many processes involve moderately corrosive media, cooling water, or slurries. This is a sweet spot for rubber-lined valves. A great example is in Flue Gas Desulfurization (FGD) systems at power plants, where they handle abrasive limestone and gypsum slurries. The cost-effective CI or DI valve bodies are ideal for the large-diameter, low-pressure piping common in these plants, providing a reliable solution without the high cost of exotic alloys.

| Industry | Common Media | Recommended Lining | Key Advantage |

|---|---|---|---|

| Mining | Ore Slurries, Tailings | Natural Rubber | Extreme Abrasion Resistance |

| Wastewater | Sludge, Disinfectants | EPDM[^1] | Chemical Resistance, No Clogging |

| Power Plant | Limestone Slurry (FGD) | Natural Rubber, EPDM[^1] | Abrasion Resistance, Cost-Effective |

| Chemical | Moderate Acids/Alkalis | EPDM[^1], Butyl | Reliable Sealing, Low Cost |

How Do You Choose Between Rubber and Plastic Linings?

Confused about whether you need a rubber-lined or a more expensive plastic-lined valve? Choosing incorrectly means either overspending on a valve you don't need or under-specifying and facing rapid failure.

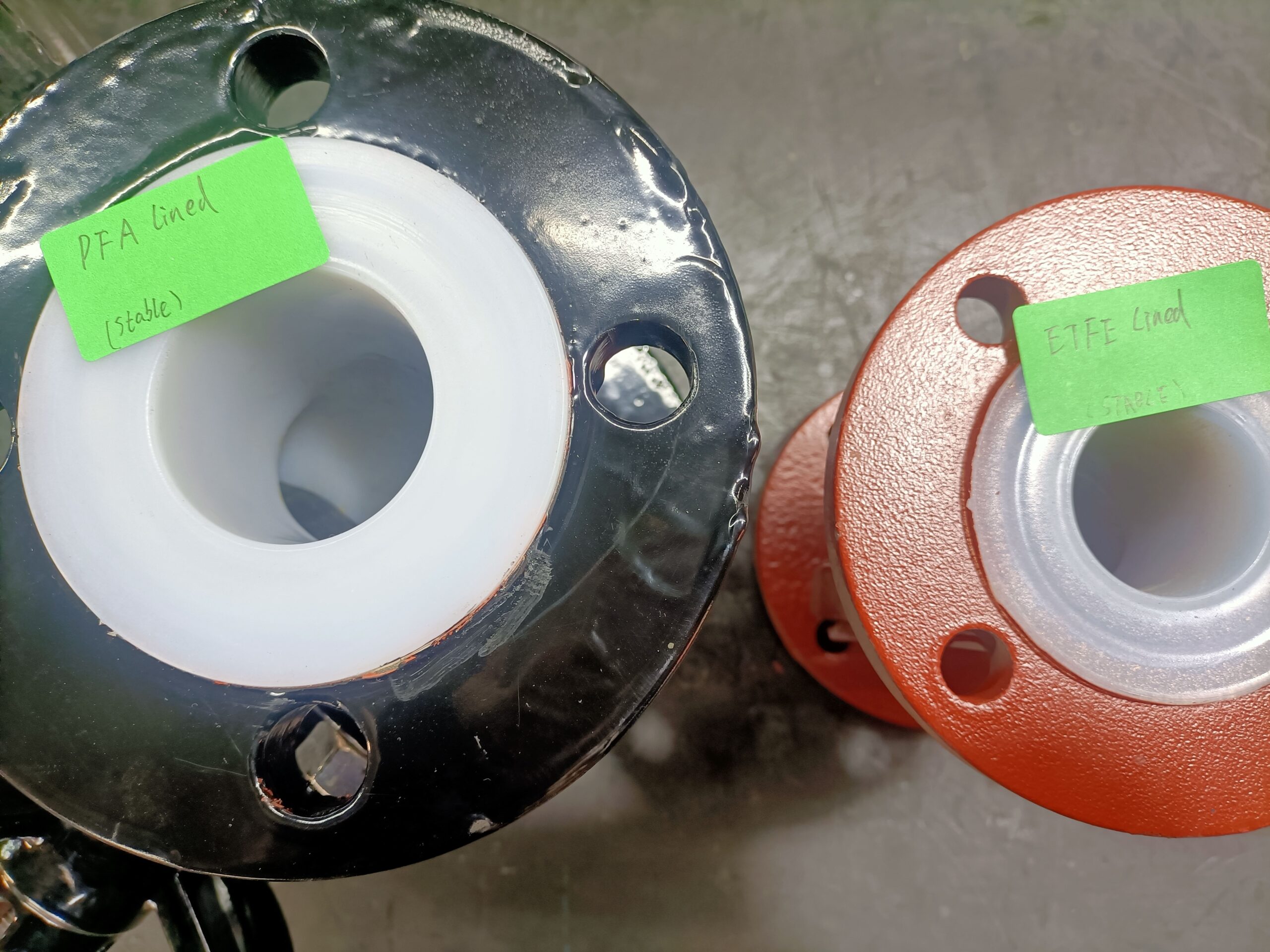

The choice is simple: choose rubber-lined valves for abrasive slurries and moderate chemicals where cost is a factor. Opt for plastic-lined (like PTFE/PFA) for highly corrosive acids, solvents, and high-purity applications, even though they are less suited for heavy abrasion.

This is one of the most common questions I get from clients. They see the price difference between a rubber-lined valve and a PFA-lined one and want to know if the extra cost is justified. The answer is always: it depends entirely on your media. Thinking about it in terms of "wear resistance" versus "chemical resistance" makes the decision much clearer.

The Case for Rubber Linings

Think of rubber as the tough, flexible option. Its primary strength is abrasion resistance. When sharp, hard particles in a slurry hit the lining, the rubber flexes and absorbs the impact, then bounces back. It's like the difference between throwing a rock at a brick wall versus a rubber tire. This resilience makes it last far longer in gritty applications. It's also more cost-effective. For the vast majority of water, slurry, and moderate chemical applications, a rubber-lined valve is the most economical and durable choice. Our DI and CI valve bodies pair perfectly with these linings for a robust, budget-friendly package.

When Plastic Linings Are Necessary

Plastic linings, such as PTFE or PFA, are the specialists for extreme chemical corrosion. They offer nearly universal chemical resistance and can handle aggressive acids, bases, and solvents that would quickly eat away at any rubber material. They are also used in high-purity applications where preventing any contamination is essential. However, these materials are harder and less flexible than rubber. This makes them more susceptible to damage from physical abrasion. They are also significantly more expensive due to the cost of the raw materials and the complex manufacturing process. You choose a plastic lining when chemical attack is your number one enemy, and abrasion is a secondary concern.

Making the Right Call

So, how do you decide? Ask yourself two questions:

- Is my media primarily abrasive (like sand, slurry, or solids)? If yes, start with rubber.

- Is my media extremely corrosive (like concentrated sulfuric acid or aggressive solvents)? If yes, you need plastic.

For many general industrial processes, a high-quality EPDM[^1] or NBR[^3] rubber lining provides a perfect balance of chemical resistance, excellent durability, and a much lower total cost of ownership.

| Feature | Rubber Lining (e.g., EPDM[^1], Natural) | Plastic Lining (e.g., PTFE, PFA) |

|---|---|---|

| Primary Strength | Abrasion Resistance | Chemical Resistance |

| Cost | Lower | Higher |

| Best For | Slurries, Powders, Water, Moderate Chemicals | Aggressive Acids, Solvents, High-Purity Media |

| Weakness | Limited resistance to strong solvents/acids | Lower resistance to physical abrasion |

| Flexibility | High | Low to Moderate |

Conclusion

Rubber-lined diaphragm valves are a durable, reliable, and cost-effective choice for abrasive and moderately corrosive jobs. Understanding their features and best uses helps you select the perfect valve for your system.

[^1]: Discover the various applications of EPDM lining in valves and its advantages in water treatment. [^2]: Explore the critical role of diaphragm valves in water treatment systems and their efficiency. [^3]: Explore the properties of NBR and its suitability for oil and fuel applications in valves. [^4]: Understand the benefits of natural rubber in diaphragm valves for high-abrasion applications. [^5]: Learn about the weir-style body design and its benefits for handling abrasive media. [^6]: Understand the significance of abrasion resistance in valve materials for harsh environments. [^7]: Learn about chemical resistance in valve materials and its importance for safety and reliability. [^8]: Explore the advantages of rubber-lined diaphragm valves for durability and cost-effectiveness in abrasive conditions. [^9]: Explore the applications of pneumatic valves in automated control systems for efficiency.