Struggling with leaking, uneven valve linings? These common issues cause downtime and high costs. A better lining process is the answer to reliable, long-lasting performance.

A rubber-lined diaphragm valve[^1] uses an elastic rubber interior for excellent abrasion resistance. It's ideal for handling slurries and semi-solids in industries like mining and water treatment. The key to its performance lies in the lining application method[^2], which prevents leaks and extends service life.

Now that we know the basics, let's explore why this valve is a go-to choice for so many industries. But more importantly, I'll share a common problem with these valves that many people overlook, and how we solved it. It's a detail that makes all the difference in performance and reliability.

What Makes Rubber-Lined Valves a Top Choice for Abrasive Applications?

Abrasive slurries grinding down your valves? This constant wear leads to frequent replacements and operational headaches. A valve designed for durability is what you need for tough media.

Rubber-lined diaphragm valves excel in abrasive applications because their elastic rubber lining absorbs impact and resists wear from particles. This makes them perfect for mining, wastewater treatment, and chemical processing, ensuring reliable performance and a longer lifespan where other valves would quickly fail.

When you're dealing with fluids that contain hard, sharp particles, like in mining or wastewater treatment, standard metal valves can erode quickly. This is where the unique properties of rubber really shine.

Why Rubber Excels Against Abrasion

Unlike rigid materials that chip, crack, or wear away when struck by abrasive particles, rubber is elastic. Think of it like a trampoline. When a particle hits the rubber surface, the lining flexes, absorbs the energy, and bounces back to its original shape. This resilience drastically reduces material loss over time. I've seen countless applications where a metal valve would last only a few months, but a rubber-lined diaphragm valve[^1] continues to perform reliably for years under the exact same conditions. The smooth, weir-type flow path of a diaphragm valve also helps minimize turbulence, which further reduces wear on the lining and the diaphragm itself. It’s a simple but incredibly effective design for handling the toughest media.

Common Rubber Lining Materials and Their Uses

Not all rubber is the same. Choosing the right type of rubber lining is critical for ensuring long service life. We offer a range of options to match specific operational needs.

| Lining Material | Key Properties | Best For... |

|---|---|---|

| EPDM[^3] | Excellent resistance to water, steam, acids, and alkalis. | Water treatment, chemical processing, and general industrial use. |

| NBR (Nitrile)[^4] | Superior resistance to oils, fuels, and solvents. | Petrochemical industry, applications with oily media. |

| Natural Rubber | High tensile strength and excellent abrasion resistance. | Mining slurries, sand and gravel, highly abrasive materials. |

| Butyl[^5] | Low gas permeability, good chemical resistance. | Applications requiring gas-tight seals, some chemical services. |

I always advise my clients to be very specific about their process fluid. A client once used an EPDM[^3]-lined valve for an oil-based slurry, and it failed quickly because EPDM[^3] swells in contact with oil. We switched them to an NBR-lined valve, and the problem was solved. This level of detail is why a partnership with an experienced manufacturer is so important.

Why Do So Many Rubber-Lined Diaphragm Valves Fail Prematurely?

Ever had a new valve fail from a detached lining? It's frustrating and costly, stopping your entire operation. This failure is often due to a hidden flaw.

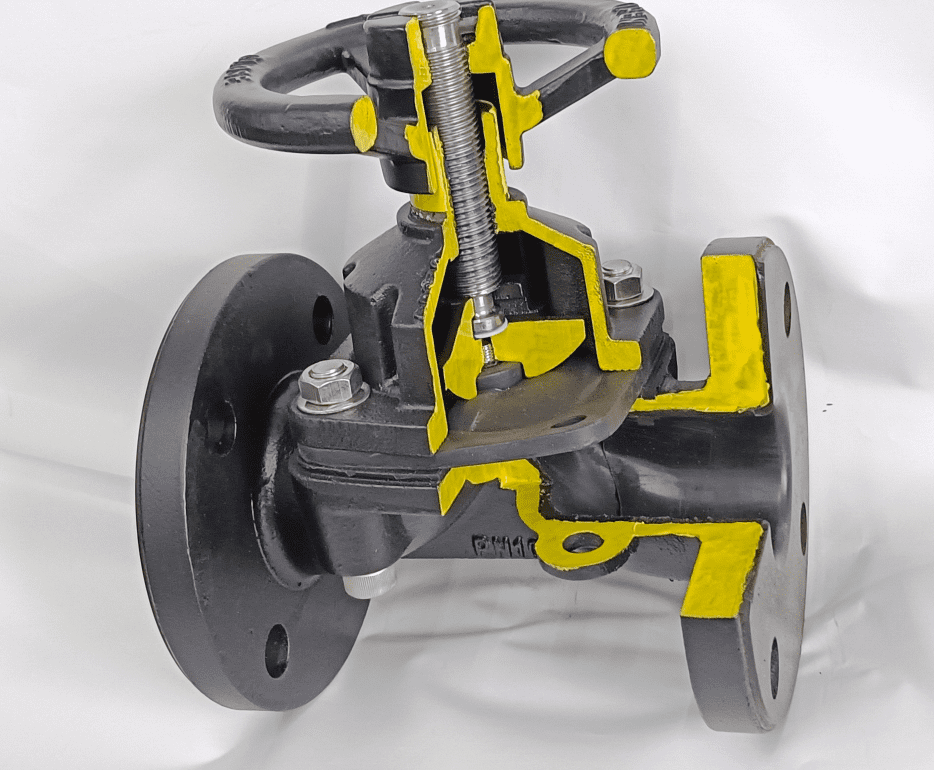

Many rubber-lined valves fail because of the manual lining process[^6]. This old method creates seams, uneven surfaces, and weak adhesion. Over time, the lining can peel away, causing leaks, contamination, and complete valve failure, leading to unexpected downtime and replacement costs.

For years, I've heard the same complaints from new clients. They buy rubber-lined valves expecting them to last, only to see them fail from lining delamination. The root cause isn't the rubber itself, but how it was applied to the valve body.

The Problems with Manual Hand-Lining

The traditional method for lining a valve body is manual application. In this process, workers cut sheets of rubber, apply an adhesive, and press the pieces into the valve body by hand. While it's a low-cost method, it is filled with potential problems that compromise the valve's integrity from day one. I remember visiting a client's plant where a series of their new valves had failed. We cut one open, and the lining peeled off like a cheap sticker. It was a classic case of poor manual application.

These are the main flaws:

- Seams: Every place where two pieces of rubber meet creates a seam. Each seam is a potential weak point where corrosive media can penetrate, attack the adhesive, and cause the lining to lift.

- Uneven Surfaces: It's nearly impossible to achieve a perfectly smooth surface by hand. These small bumps and dips create turbulence in the flow, which accelerates wear and can trap particles.

- Air Pockets: Tiny air bubbles can get trapped between the rubber and the metal body during application. Under pressure or temperature changes, these bubbles can expand, forming blisters that lead to catastrophic lining detachment.

- Inconsistent Adhesion: The quality of the bond depends entirely on the skill and care of the individual worker. This leads to massive variations in quality, even within the same batch of valves.

How Does Mechanical Vulcanization Create a Superior Rubber Lining?

Worried about lining detachment and leaks in your valves? This risk can compromise your entire system. A modern manufacturing process offers a permanent, seamless solution for total reliability.

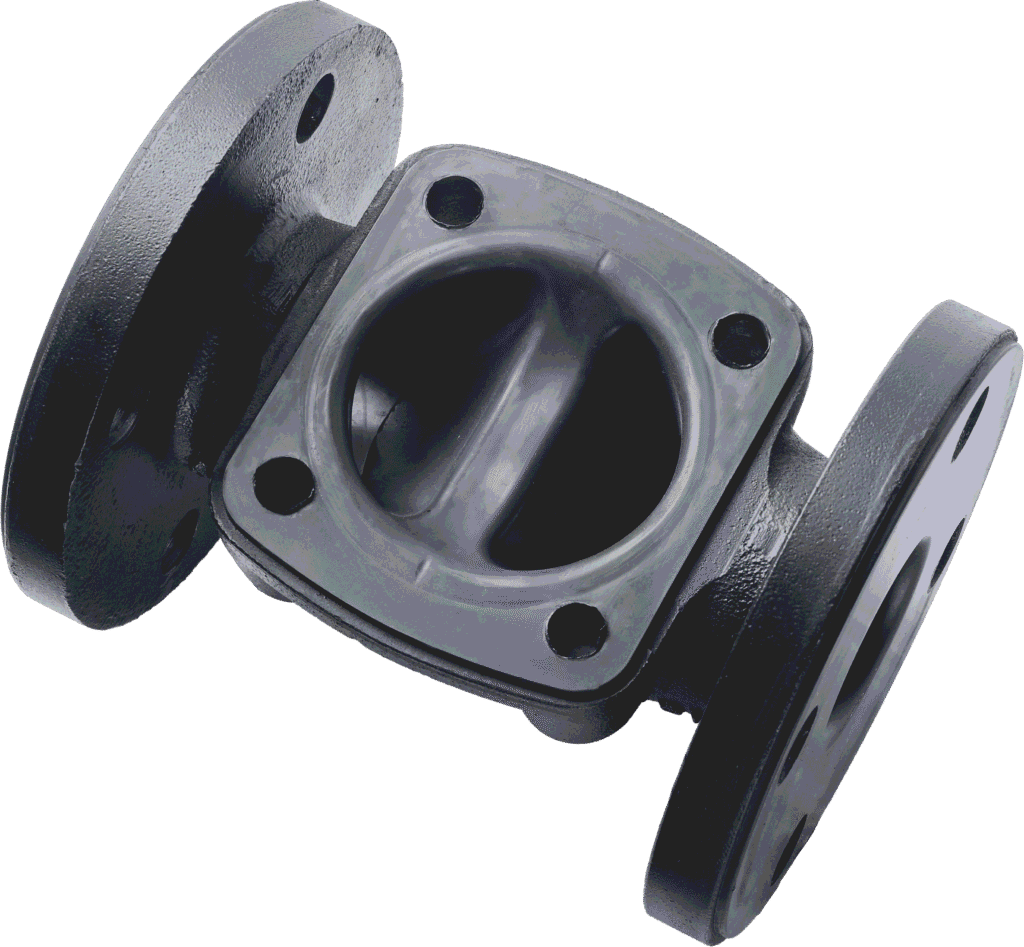

Mechanical vulcanization is an advanced process where raw rubber is molded directly into the valve body under high heat and pressure. This creates a seamless, chemically bonded lining. The result is a perfectly smooth surface with no weak points, ensuring superior durability and zero risk of detachment.

After seeing so many failures caused by manual lining, we knew we had to find a better way. Our investment in the mechanical vulcanization process was a game-changer. It allows us to offer our clients a valve they can truly trust, eliminating the common failures they've grown to expect from other suppliers.

The Mechanical Vulcanization Process Explained

This process is far more controlled and reliable than manual work. First, we prepare the cast iron valve body by sandblasting it to create a clean, textured surface for maximum adhesion. Then, the body is placed into a precision-engineered mold. We introduce a specific amount of uncured raw rubber compound. The mold is then closed, and intense heat and pressure are applied. This does two things at once: it vulcanizes the rubber, giving it its durable, elastic properties, and it forms an incredibly strong chemical bond between the rubber and the metal valve body. The lining becomes an integral part of the valve, not just a layer stuck on top.

Comparing Manual vs. Mechanical Lining

The difference in quality is night and day. For our clients, this means a valve that performs better, lasts longer, and provides a much lower total cost of ownership. The peace of mind that comes from eliminating the risk of lining failure is invaluable.

| Feature | Manual Hand-Lining | Mechanical Vulcanization (Our Process) |

|---|---|---|

| Seams | Multiple seams, creating weak points. | Completely seamless. |

| Surface Finish | Uneven, can cause turbulence. | Perfectly smooth and uniform. |

| Adhesion | Weaker adhesive bond, inconsistent. | Strong chemical bond, permanent. |

| Consistency | Varies greatly by worker. | Highly consistent and repeatable. |

| Lifespan | Shorter, unpredictable. | Significantly longer and more predictable. |

| Risk of Failure | High risk of detachment and leaks. | Virtually zero risk of detachment. |

This superior process is why our rubber-lined valves look and feel different. The smooth, flawless interior gives end-users confidence and drastically reduces the risks and costs associated with valve maintenance and replacement.

Conclusion

A mechanically vulcanized rubber lining provides a seamless, durable, and reliable solution for abrasive applications, eliminating common failures and reducing long-term costs for your operation.

[^1]: Explore the advantages of rubber-lined diaphragm valves for enhanced durability and performance in various industries. [^2]: Discover how the method of lining application can significantly impact the reliability and lifespan of valves. [^3]: Learn about EPDM rubber's unique properties and its applications in various industries. [^4]: Discover the benefits of NBR rubber and its applications in the petrochemical industry. [^5]: Explore how Butyl rubber is utilized in applications requiring gas-tight seals. [^6]: Understand the limitations of manual lining processes and their impact on valve performance.