Struggling with leaking or corroded valves in your pipeline? Finding the right valve for harsh chemicals can be a constant headache and a costly problem for your business.

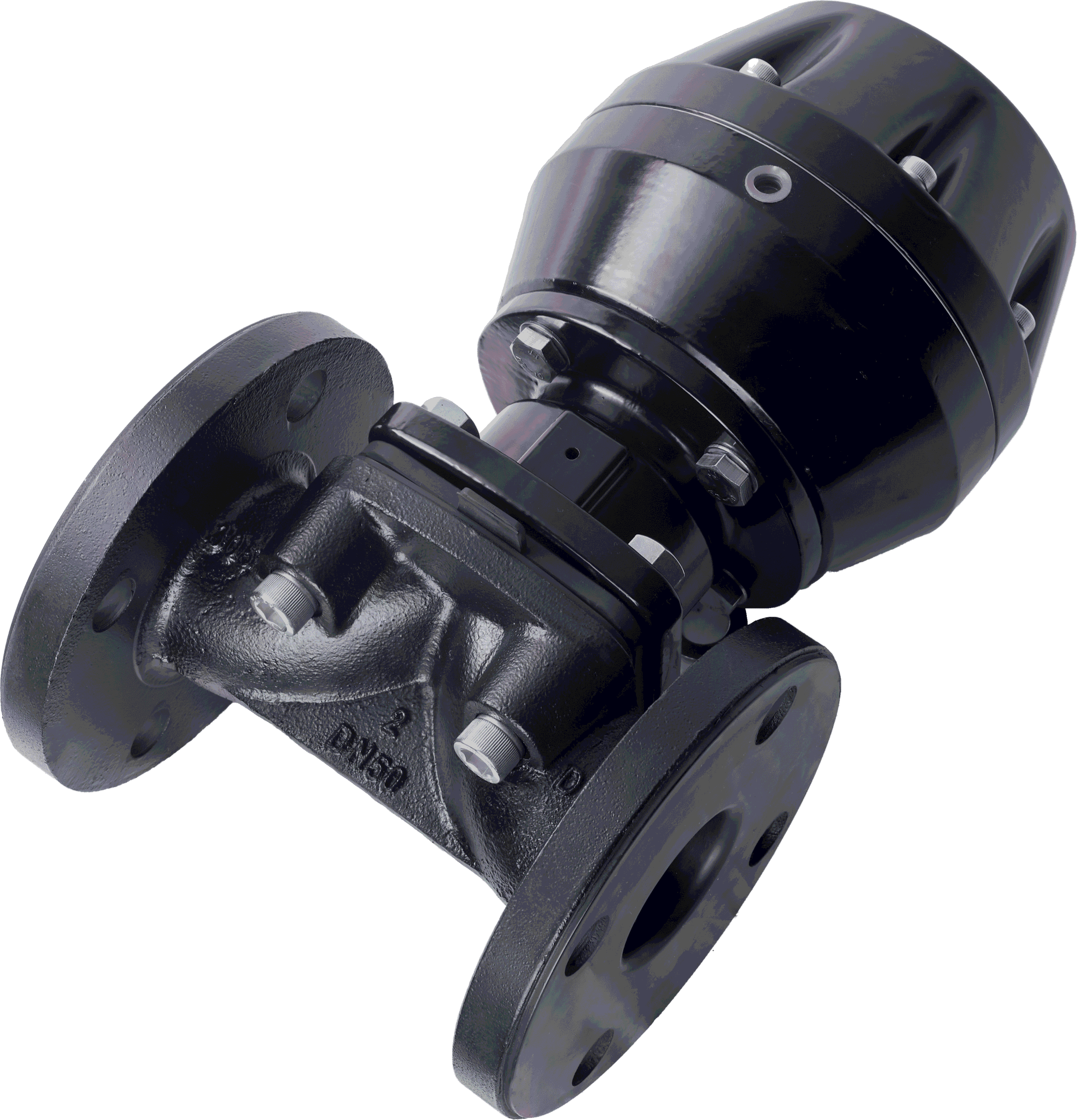

A diaphragm valve[^1] is a simple, effective valve that uses a flexible diaphragm to control fluid flow. It's ideal for corrosive, abrasive, or high-purity fluids because the diaphragm isolates the media from all other valve parts, preventing contamination and leaks.

I've been in the valve manufacturing business for years, and I've seen countless clients dealing with the wrong valve for the job. They face constant maintenance, unexpected downtime, and even safety hazards. The beauty of the diaphragm valve[^1] lies in its simplicity, but understanding how that simplicity translates into powerful performance is key. It's not the right valve for every single situation, but for its specific niche, it's often the most reliable and cost-effective solution you can find. Let's walk through what makes this valve special and where it truly shines.

How Does a Diaphragm Valve Actually Control Flow?

Wondering about the inner workings of these valves? The simple design is key to their reliability, but there are two main types you need to know about to make the right choice.

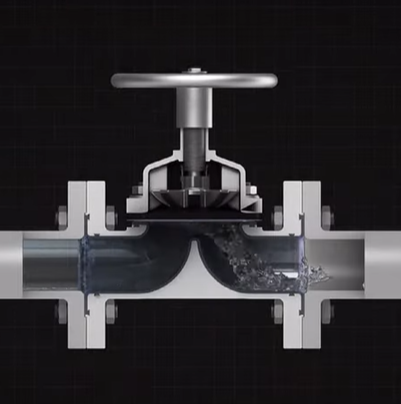

A diaphragm valve[^1] works by pressing a flexible diaphragm against a solid part of the valve body to stop flow. The two main designs are weir-type, which has a raised lip, and straight-through, which offers an unobstructed path when open.

When you look inside a diaphragm valve[^1], you'll see it's quite different from a ball or gate valve. The entire mechanism is separated from the fluid path by a flexible sheet, which is the diaphragm. This is the valve's biggest advantage. Since the fluid only touches the valve body's inner lining and the diaphragm itself, you don't need to worry about the stem, bonnet, or other mechanical parts corroding. This also means there's no need for gland packing, which is a common source of leaks in other valve types.

There are two primary designs you'll encounter:

Weir-Type Diaphragm Valves

This is the most common design. Inside the valve, there's a raised "weir" or saddle in the middle of the flow path. To close the valve, the compressor pushes the diaphragm down onto this weir, creating a bubble-tight seal. This design is great for throttling and gives you better flow control compared to the alternative. However, the weir can trap solids, so it's not ideal for heavy slurries.

Straight-Through Diaphragm Valves

As the name suggests, this design has a flat bottom and provides a completely straight, unobstructed path when the valve is open. The diaphragm has to travel further to close against the bottom of the valve. Because there's no weir to trap particles, this type is excellent for handling slurries, sludges, and other viscous media.

| Feature | Weir-Type | Straight-Through |

|---|---|---|

| Flow Path | Contoured over a weir | Unobstructed, straight line |

| Best For | Clean or corrosive liquids, throttling | Slurries, sludges, viscous fluids |

| Sealing | Shorter diaphragm travel, easier seal | Longer diaphragm travel, more force needed |

| Drainage | Can trap fluid | Drains completely |

| Common Use | Chemical dosing, water treatment | Mining, wastewater sludge lines |

What Are Diaphragm Valves Made Of?

The right material can mean the difference between a long service life and early failure. Choosing incorrectly for corrosive media can lead to disaster and expensive downtime for your operations.

Diaphragm valves typically have a cast iron (CI) or ductile iron (DI) body for strength and cost-effectiveness. The wetted parts are protected by a corrosion-resistant lining (plastic or rubber) and the diaphragm itself, which isolates the fluid.

A diaphragm valve[^1] is a system of materials working together. The outer body provides the structural strength, while the inner lining and diaphragm provide the chemical resistance[^2]. At our factory, we start with high-quality valve bodies. We use ductile iron (DI) and cast iron (CI), which are perfect for the low-to-medium pressure applications where these valves excel. We cast them using a resin-coated sand process, which results in a much smoother surface and fewer imperfections compared to traditional methods. This isn't just about looks; a smoother surface allows for a better bond with the lining.

The real magic happens with the lining and the diaphragm. These are the only two parts that ever touch your process fluid.

Plastic Linings

For the most aggressive chemicals, like strong acids and alkalis, plastic linings are the answer. PFA is often considered the king here due to its outstanding chemical resistance across a wide temperature range.

Rubber Linings

For applications involving abrasion, slurries, or less aggressive chemicals, rubber linings[^3] are a durable and cost-effective choice. Materials like EPDM are fantastic for water treatment chemicals, while NBR is great for oils and fuels.

We apply these linings using a mechanical process. This ensures a seamless, uniform layer with no weak spots, which is critical for long-term reliability in corrosive environments.

| Material | Type | Best For | Temperature Limit (Approx.) |

|---|---|---|---|

| PFA | Plastic | Strong acids, alkalis, solvents | Up to 200°C (392°F) |

| PTFE | Plastic | Wide range of chemicals, high purity | Up to 200°C (392°F) |

| ETFE | Plastic | Good chemical and abrasion resistance | Up to 150°C (302°F) |

| EPDM | Rubber | Water, steam, acids, alkalis | Up to 120°C (248°F) |

| NBR | Rubber | Oils, fuels, solvents | Up to 100°C (212°F) |

When Is a Diaphragm Valve the Best Choice for Your System?

Are you unsure if a diaphragm valve[^1] fits your specific needs? Using the wrong valve type can lead to poor performance, frequent maintenance, and unnecessary costs down the line.

Use a diaphragm valve[^1] for low-to-medium pressure applications involving corrosive, abrasive, or viscous fluids. They are excellent for chemical plants, wastewater treatment, and power plant flue gas desulfurization, where reliability and contamination prevention are critical.

I often tell clients that a diaphragm valve[^1] is a specialist, not a generalist. If you have a high-pressure, high-temperature steam line, this is not the valve for you. But if you're dealing with something nasty, sticky, or something you simply can't allow to leak, this valve becomes the hero. For example, a client needed to control the flow of room-temperature sodium hydroxide. For this highly corrosive fluid, we recommended a ductile iron valve body with a PFA lining[^4]. The PFA provides total protection from the chemical, and the DI body provides the necessary strength at a much lower cost than a solid alloy valve.

The key is to match the valve to the job. Diaphragm valves are ideal because their simple, sealed design solves many common industrial problems.

Where They Shine (Pros):

- Corrosive Fluids: The lining and diaphragm protect all working parts. This is their number one application.

- Abrasive Slurries: The straight-through design offers a clear path that prevents clogging, and durable rubber linings[^3] resist wear.

- Bubble-Tight Shutoff: The flexible diaphragm creates a perfect seal against the weir or valve bottom.

- No Stem Leaks: The diaphragm completely isolates the bonnet and stem, eliminating the need for packing and preventing fugitive emissions.

- Easy Maintenance: You can replace the diaphragm with the valve body still in line, which drastically reduces downtime.

Where They Have Limits (Cons):

- Temperature & Pressure: The flexible diaphragm and lining materials limit their use to moderate conditions.

- Throttling Precision: While a weir-type valve can throttle, it doesn't offer the fine control of a globe valve. Its control range is quite small.

I always advise customers to be honest about their operating conditions. If you need precise control, we might discuss another solution. But for reliable on/off or basic throttling of tough media, the diaphragm valve[^1] is hard to beat.

How Can You Get a Diaphragm Valve That Perfectly Matches Your Needs?

Off-the-shelf valves don't always fit your exact requirements. You might need specific dimensions, materials, or branding, which can be hard to find from standard suppliers.

The best way is to partner with an OEM/ODM manufacturer[^5] like us. We can customize everything from the valve body and lining materials to flange standards and branding, ensuring you get the perfect valve for your application and market.

Many of our clients are distributors, e-commerce sellers, or brands looking to expand their product line. They can't just buy a standard valve; they need a product that fits their market and their customers' specific systems. This is where working directly with a factory makes all the difference. As an OEM/ODM supplier, our entire business is built around customization and partnership. We don't just sell you a valve; we build your valve.

The process starts with your requirements. Do your customers primarily use American ANSI 150 flanges, or do they need British PN standards? Are you serving the chemical industry, which needs PFA lining[^4]s, or the mining sector, which needs abrasion-resistant natural rubber? We can accommodate all of these variables. Our process covers the entire product lifecycle:

- Concept & Design: We work with you to define the exact specifications.

- Mold Development: We use all-new molds for our clients' projects, ensuring a flawless appearance that reflects your brand's quality. This is a huge advantage over factories using old, worn-out molds.

- Testing & Certification: We ensure the product meets all necessary performance and quality standards.

- Mass Production: Our streamlined production allows us to deliver a full container in 35-45 days, which is significantly faster than many competitors.

This flexibility allows you to offer a unique, high-quality product to your customers without the massive investment of setting up your own production line. You get a valve with factory-direct quality, customized for your brand, and a reliable supply chain to support your growth.

Conclusion

Diaphragm valves are simple, reliable, and cost-effective solutions for controlling corrosive and abrasive fluids. By choosing the right design and materials, you ensure leak-free performance and minimal maintenance.

[^1]: Explore this resource to understand the unique benefits and applications of diaphragm valves in various industries. [^2]: Understand the materials that provide superior chemical resistance to enhance the longevity of your valves. [^3]: Learn how rubber linings can enhance the durability and performance of diaphragm valves in various applications. [^4]: Explore the benefits of PFA lining in diaphragm valves for handling aggressive chemicals safely. [^5]: Understand how partnering with an OEM/ODM manufacturer can provide tailored solutions for your valve needs.