Struggling to find a valve that handles corrosive or abrasive fluids without leaking or contamination? This can lead to costly downtime and safety risks in your plant.

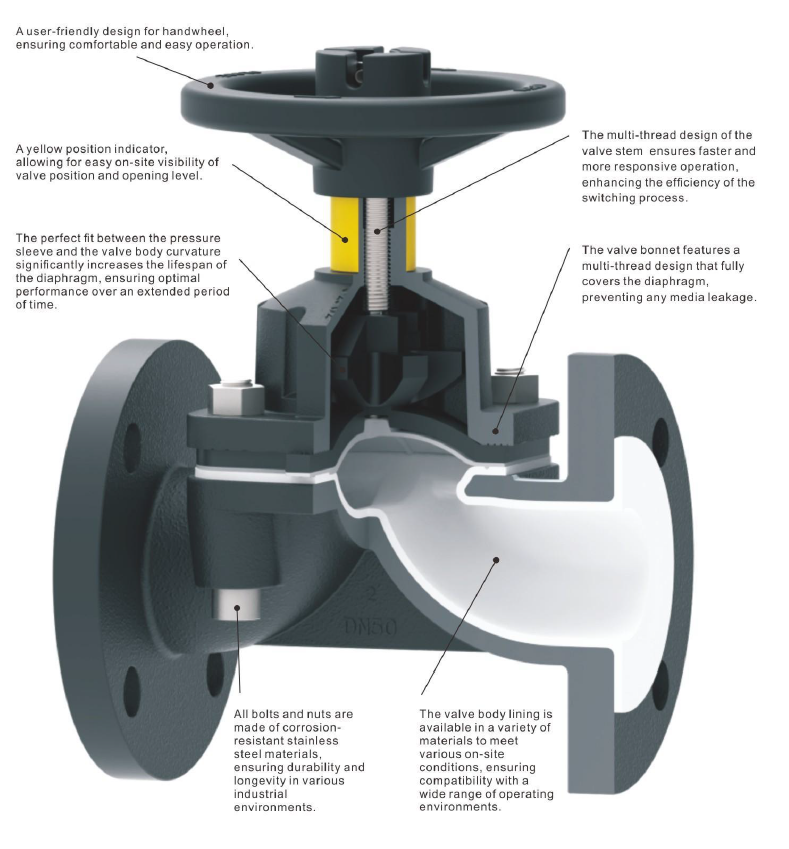

Diaphragm valves[^1] are widely used to control powders, slurries, liquids, and gases across industries like chemical processing[^2], power generation[^3], and wastewater treatment[^4]. Their unique design isolates the fluid from moving parts, preventing contamination, reducing wear, and ensuring reliable performance[^5] in demanding environments.

Why are diaphragm valves essential in the chemical industry?

Finding a valve that can withstand aggressive chemicals without corroding or failing is a constant challenge. A leak in a chemical line isn't just a mess; it's a serious safety hazard.

In the chemical industry, diaphragm valves are essential for handling acids, alkalis, solvents, and slurries. The valve's lining and diaphragm create a barrier, protecting metal parts from corrosion and preventing leaks, which is crucial for both safety and process purity.

| Lining Material | Common Applications & Advantages | Limitations |

|---|---|---|

| PFA/PTFE | Strong acids, bases, solvents. Excellent chemical resistance[^7]. | Higher cost, less suitable for abrasive slurries[^8]. |

| EPDM Rubber[^9] | Dilute acids, alkalis, water-based solutions. Good general purpose. | Not suitable for oils or hydrocarbon solvents. |

| NBR Rubber | Oils, fuels, and some solvents. Good abrasion resistance[^10]. | Poor resistance to strong acids and ozone. |

This ability to customize the lining makes diaphragm valves a go-to solution for the complex and hazardous fluids found in chemical and petrochemical processing[^2].

How do diaphragm valves handle tough jobs in power plants?

Power plants, especially those with flue gas desulfurization[^11] (FGD) systems, deal with highly abrasive and corrosive slurries. Limestone and gypsum can quickly wear out standard valves, causing blockages and frequent shutdowns.

Diaphragm valves[^1] excel in power plants by managing abrasive slurries[^8] like limestone and gypsum in FGD systems. Their smooth, open flow path prevents clogging, and durable rubber linings resist wear, ensuring reliable operation and reducing maintenance costs.

- Water Treatment: Handling acids and alkalis for demineralization.

- Flue Gas Desulfurization (FGD): Controlling limestone and gypsum slurries.

- Ash & Slag Handling: Managing abrasive waste materials. In each case, the diaphragm valve's simple, effective design proves its worth.

What makes diaphragm valves a top choice for wastewater treatment[^4]?

Wastewater treatment plants use a variety of chemicals for dosing, and they also handle sludge with high solids content. This combination of corrosion and abrasion can be tough on equipment, leading to leaks and blockages.

Diaphragm valves[^1] are ideal for wastewater treatment[^4] because their leak-proof seal prevents chemical spills and their unobstructed flow path handles sludge without clogging. The protective linings stand up to corrosive dosing chemicals like sodium hypochlorite and flocculants.

Here's how diaphragm valves fit into a typical wastewater treatment[^4] process:

| Process Stage | Application | Why Diaphragm Valves are a Good Fit |

|---|---|---|

| Primary Treatment | Sludge and scum lines | Handles high solids content without clogging. |

| Chemical Dosing | Dosing coagulants, flocculants, pH adjusters | Leak-tight seal prevents chemical waste and hazards. |

| Secondary Treatment | Activated sludge return and waste lines | Reliable shut-off and control of abrasive and biological media. |

| Disinfection | Sodium hypochlorite dosing | Excellent chemical resistance with appropriate linings (e.g., EPDM). |

Whether it's a manually operated valve for infrequent use or a pneumatic one for automated process control, the core benefits of reliability and containment remain the same.

Conclusion

Diaphragm valves[^1] are trusted in chemical plants, power stations, and wastewater facilities because they solve core problems of corrosion, abrasion, and contamination reliably and cost-effectively.

[^1]: Explore this link to understand the unique design and functionality of diaphragm valves in various industries. [^2]: Find out how diaphragm valves enhance safety and efficiency in chemical processing environments. [^3]: Understand the role of diaphragm valves in power generation and their impact on operational reliability. [^4]: Explore how diaphragm valves contribute to effective wastewater treatment and prevent leaks. [^5]: Learn about the design features that contribute to the reliable performance of diaphragm valves. [^6]: Learn about PFA lining and its benefits for diaphragm valves in corrosive environments. [^7]: Discover materials that provide excellent chemical resistance for diaphragm valves in harsh environments. [^8]: Discover the advantages of diaphragm valves in managing abrasive slurries and preventing equipment wear. [^9]: Discover the benefits of EPDM rubber linings in diaphragm valves for various applications. [^10]: Find out how diaphragm valves are designed to resist abrasion and extend service life. [^11]: Learn about flue gas desulfurization and the critical role diaphragm valves play in this process. [^12]: Find out how diaphragm valves provide leak-proof seals for safe chemical dosing in treatment plants.