Struggling with valves that leak or clog with abrasive fluids[^1]? These failures cause costly downtime. Diaphragm valves[^2] offer a unique solution, but you need to know their limits first.

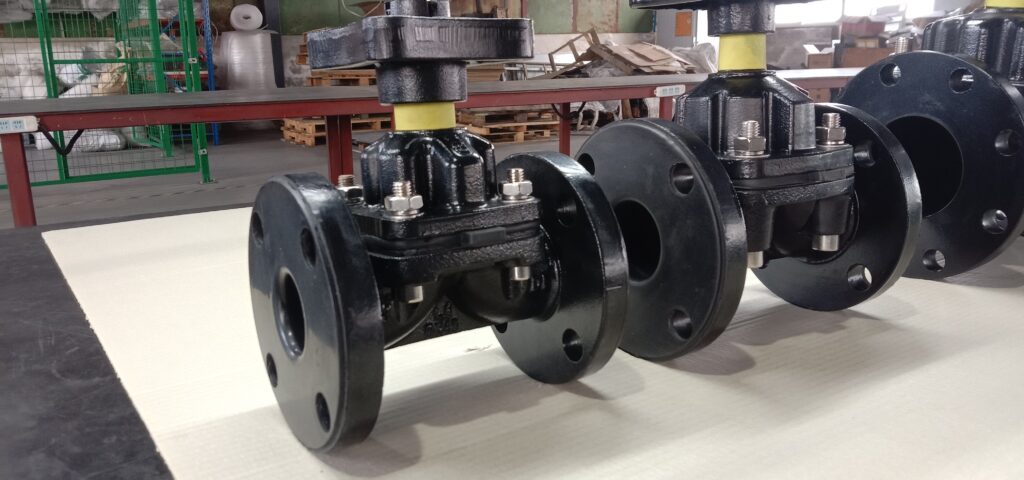

Diaphragm valves[^2] excel in handling corrosive, abrasive, and high-purity fluids[^3] because the diaphragm isolates the media from all moving parts. This leak-proof design[^4] prevents contamination. However, their main limitations are a restricted temperature and pressure range[^5] due to the diaphragm material's properties.

Now that you have a quick overview, you're probably wondering if the advantages outweigh the disadvantages for your specific needs. In my years of manufacturing these valves, I've seen where they shine and where they fall short. Let's break it down further so you can make an informed decision.

What Makes Diaphragm Valves So Effective for Corrosive and Abrasive Media?

Tired of valves failing under corrosive or abrasive conditions? These failures risk safety and create expensive messes. Discover how a diaphragm valve's unique design provides a robust, leak-proof solution.

Diaphragm valves[^2] are highly effective because their diaphragm isolates the fluid from the valve's operating mechanism. This design prevents leaks to the atmosphere and protects internal parts from corrosion and abrasion. The smooth, glandless flow path also minimizes clogging with slurries or solids.

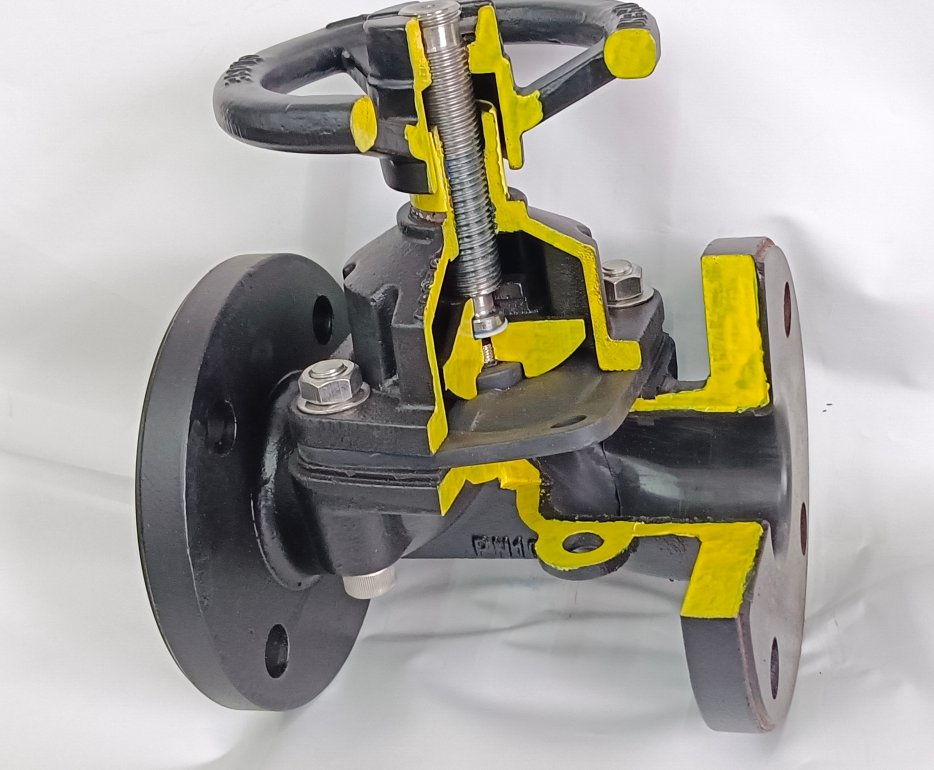

The real genius of a diaphragm valve is its simplicity. The diaphragm isn't just a seal; it's a dynamic barrier that completely separates the fluid from the bonnet assembly, where the stem and handwheel are. I've seen this design save clients countless headaches. This total isolation has two massive benefits. First, it creates a bubble-tight, zero-leakage seal to the outside world. For anyone handling hazardous chemicals[^6] like acids or caustics, this isn't just a feature—it's a critical safety requirement. You eliminate the risk of dangerous fumes or spills that can happen with traditional packed-stem valves.

Second, it protects all the valve's operating parts from whatever is flowing through the pipe. Think about abrasive slurries in a mining operation or corrosive chemicals in a treatment plant. In other valves, these materials slowly eat away at the stem, packing, and other internals, leading to failure. With a diaphragm valve, the media only ever touches the valve body[^7] and the diaphragm. At our factory, we enhance this protection by lining the valve body[^7] with robust materials like PFA, PTFE, or various types of rubber. This creates a fortress against corrosion and abrasion. I remember a client who was replacing ball valves every three months in an acid line. After switching to our PFA-lined diaphragm valves, they've been running for over two years without a single issue. That's the kind of reliability this design delivers.

| Advantage | Why It Matters for Your Business | Our Solution |

|---|---|---|

| Leak-Proof Seal | Prevents loss of media and eliminates environmental and safety risks. | The diaphragm creates an impassable barrier to the atmosphere. |

| Excellent Corrosion Resistance | Reduces downtime and maintenance costs by extending valve life. | We offer a range of plastic (PFA, PTFE) and rubber (EPDM, NBR) linings. |

| No Media Contamination | The isolated design ensures media purity, essential for sensitive processes. | No lubricants or packing can ever touch the process fluid. |

| Handles Slurries & Solids | The unobstructed weir or straight-through flow path prevents clogging. | Our designs ensure a smooth passage, minimizing pressure drop and buildup. |

What Are the Main Limitations I Should Consider with Diaphragm Valves?

Worried a diaphragm valve won't handle your system's pressure or temperature? A mismatch can lead to diaphragm failure and costly line shutdowns. Knowing these limitations is crucial for success.

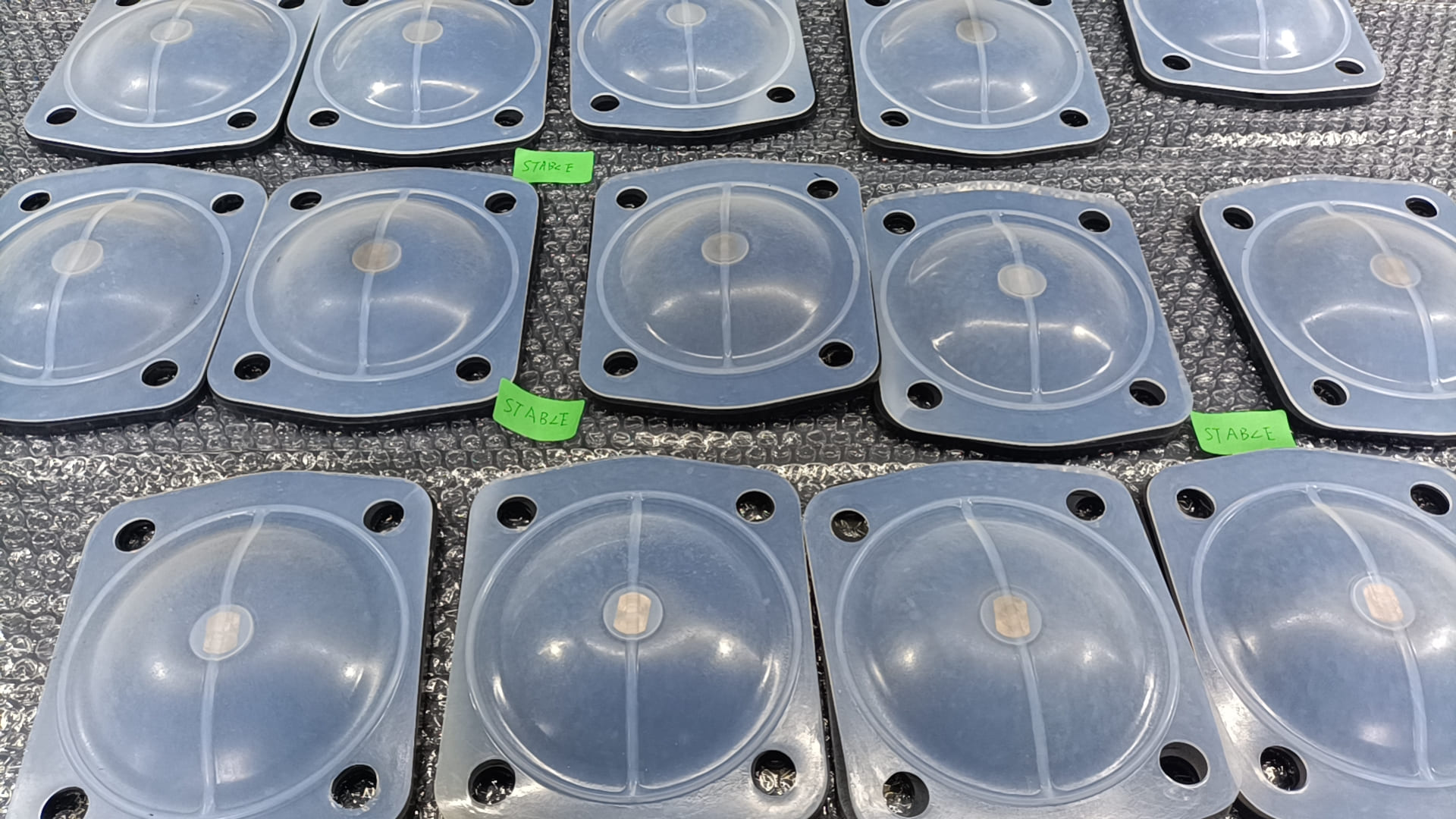

The primary limitations of diaphragm valves are their pressure and temperature ratings, which are determined by the flexible diaphragm material. They are generally not suitable for high-pressure or high-temperature services. The diaphragm can also wear out over time, requiring periodic replacement, especially in abrasive applications.

Every valve has its limits, and for diaphragm valves, it all comes down to the diaphragm itself. This flexible component is the valve's greatest strength but also its main source of limitations. Because it needs to be flexible to open and close, the materials used (like rubber or PTFE) simply can't withstand the same extreme pressures and temperatures as a solid metal gate or ball. I always tell my clients to be very clear about their operating conditions. Pushing a diaphragm valve beyond its specified limits is a recipe for failure. A ruptured diaphragm doesn't just stop flow; it can shut down your entire line and, in a worst-case scenario, compromise the isolation, leading to a leak.

The temperature range is also dictated entirely by the diaphragm and lining material. For example, a standard EPDM rubber[^8] diaphragm is great for many water and chemical applications, but it typically maxes out around 120°C (250°F). If your process runs hotter, you might need a PTFE diaphragm, which can handle up to 150°C (300°F), but PTFE has its own limitations in terms of flexibility. Maintenance is another factor. While simple, the diaphragm is a wear part and will eventually need replacement. Think of it like the tires on a car. The frequency of replacement depends entirely on the service conditions—abrasive slurries will wear it down much faster than clean water. It’s a trade-off we must be honest about: you get a perfect seal for difficult media, but you accept these operational boundaries and a plan for periodic maintenance.

| Limitation | Impact on Application | How to Manage It |

|---|---|---|

| Limited Pressure | Not for high-pressure systems (typically < 230 PSI). | Verify your system pressure against the valve's specific rating. |

| Limited Temperature | Range is defined by diaphragm/lining (e.g., EPDM vs. PTFE). | Select the diaphragm and lining material that matches your process temperature. |

| Diaphragm Wear | Requires periodic replacement, a planned maintenance cost. | Establish a regular inspection schedule based on the severity of the service. |

| Throttling Capability | Weir-type is okay for some control, but not for precision. | Use primarily for on/off service or coarse throttling. Choose a globe valve for fine control. |

How Do I Know If a Diaphragm Valve Is Right for My Application?

Feeling uncertain about which valve is best for your specific process? A poor choice leads to operational headaches and wasted investment. Let's identify the exact applications where diaphragm valves excel.

A diaphragm valve is likely the right choice if your application involves low-to-medium pressure, corrosive chemicals, abrasive slurries, or requires zero contamination. They are ideal for industries like chemical processing, water treatment[^9], power generation[^10] (FGD systems), and mining where reliability in harsh conditions is key.

From my experience manufacturing these for clients worldwide, the decision often comes down to the media you're handling. The first question I always ask a potential customer is, "What's in the pipe?" If the answer is clean water, air, or high-pressure steam, a diaphragm valve is probably the wrong tool for the job. But if they say they're dealing with sulfuric acid, limestone slurry, sodium hypochlorite, or wastewater sludge, my eyes light up. That's where these valves truly shine. The key is matching the valve's unique strengths to the application's unique demands.

For example, in a municipal wastewater treatment[^9] plant, our cast iron valves with an EPDM rubber[^8] lining provide a cost-effective and incredibly durable solution for dosing chemicals or handling sludge. The rubber resists the chemicals, and the valve's design prevents clogging. In a high-purity chemical plant, a ductile iron valve with a thick PFA lining[^11] offers the ultimate defense against aggressive acids. The valve body[^7] provides the structural strength, while the lining and diaphragm do the hard work of containing the corrosive media. I once worked with a distributor whose customer was struggling with valve failures in a flue gas desulfurization (FGD) system at a power plant. The abrasive limestone slurry was destroying their other valves. We supplied them with our rubber-lined diaphragm valves, and the problem was solved. They are specialized tools for specialized jobs.

| Industry | Key Application | Why Diaphragm Valves Excel | Recommended Configuration |

|---|---|---|---|

| Chemical Processing | Acid/Alkali Transfer | Ultimate corrosion resistance and leak-proof safety. | DI Body, PFA/PTFE Lining |

| Water Treatment | Chemical Dosing & Sludge | Prevents leaks and handles solids without clogging. | CI/DI Body, EPDM/NBR Lining |

| Power Plants | FGD / Ash Handling | Manages abrasive and corrosive slurries reliably. | CI/DI Body, Natural Rubber Lining |

| Mining | Slurry Transport | Excellent wear resistance for high-solid content media. | CI/DI Body, Hard/Soft Rubber Lining |

Conclusion

Diaphragm valves[^2] offer unmatched sealing for corrosive and abrasive media but have pressure/temperature limits. Understanding this trade-off is key to choosing the right valve for reliable, long-term performance.

[^1]: Discover which valves are most effective for handling abrasive fluids and preventing wear. [^2]: Explore the advantages of diaphragm valves for handling corrosive and abrasive fluids in various industries. [^3]: Learn about high-purity fluids and the importance of using the right valves in their handling. [^4]: Understand the engineering behind leak-proof designs and their importance in safety and efficiency. [^5]: Find out the operational limits of diaphragm valves to ensure they fit your application. [^6]: Understand the safety measures necessary when using valves for hazardous chemicals. [^7]: Explore the materials used in valve bodies and their impact on performance and durability. [^8]: Discover the benefits of EPDM rubber in diaphragm valves and its applications. [^9]: Explore the applications of diaphragm valves in water treatment and their benefits. [^10]: Learn how diaphragm valves are utilized in power generation for handling challenging media. [^11]: Learn about PFA lining and how it enhances the performance of diaphragm valves.