Choosing the wrong diaphragm valve[^1] can lead to leaks, failures, and costly downtime. This halts production and hurts your bottom line. But understanding a few key factors ensures optimal performance.

The key factors for selecting and operating diaphragm valve[^1]s include matching the valve to your application's fluid, temperature, and pressure. Proper sizing for flow control, selecting the right materials for corrosion resistance, and choosing between manual or automated operation[^2] are also crucial for ensuring reliability and longevity.

I've seen many clients struggle with these choices over the years. It's easy to get overwhelmed by technical specifications. But it all comes down to breaking the problem into smaller, manageable pieces. Let's walk through each factor one by one, so you can make your next purchase with confidence and avoid common pitfalls. Making the right choice from the start saves a lot of time and money down the road.

How Do You Match a Valve to Your Specific Application?

Your system handles specific fluids, temperatures, and pressures. A mismatched valve could fail catastrophically. Let's make sure your valve is built for the job from day one.

To match a valve to your application, you must consider the fluid type (liquid, gas, slurry), its characteristics (corrosive, viscous, contains solids), and the system's operating temperature and pressure. This ensures the valve performs reliably without premature failure.

I once worked with a procurement manager for a chemical plant who was experiencing frequent valve failures. The problem was that the valve specified for a mild chemical line was being used for a much more aggressive acid. The lining and diaphragm simply weren't up to the task. This highlights the importance of getting the application details right from the very beginning.

Analyzing Your Fluid

The first step is always to understand what will be flowing through the valve. Is it a clean liquid like water, a highly corrosive acid, or an abrasive slurry with solid particles? Each of these requires a different approach. For example, a slurry found in a mining application or a power plant's flue gas desulfurization system needs a valve with a smooth flow path to prevent clogging and a tough lining to resist abrasion.

Understanding Temperature and Pressure

After the fluid, you must confirm the operating conditions. A valve that works perfectly at room temperature might fail if the system temperature rises above the limit of its lining or diaphragm material[^3]. Similarly, the valve's pressure rating must be higher than the maximum pressure in your system. We design our valves for medium-to-low pressure industrial applications, which covers the majority of uses in chemical, water treatment, and power plants.

| Fluid Type | Key Consideration | Recommended Lining |

|---|---|---|

| Acids & Alkalis | High corrosion resistance | Plastic (PFA, PTFE) or specific Rubber (EPDM) |

| Abrasive Slurries | Wear resistance, smooth flow path | Natural Rubber (Soft or Hard) |

| Wastewater | General chemical resistance, cost-effectiveness | EPDM, NBR |

| Solvents | Chemical compatibility | PTFE |

Why Is Valve Sizing and Flow Control So Important?

An incorrectly sized valve chokes your system or wastes energy. This inefficiency costs you money every single day. Proper sizing is essential for optimal performance and energy efficiency.

Proper valve sizing ensures the right flow rate without unnecessary pressure loss or energy waste. The flow coefficient (Cv)[^4] must match your system's needs, guaranteeing efficient operation and preventing issues like noise or excessive wear on the valve and pump.

Getting the size right is a balancing act. If the valve is too small, it will restrict flow, causing a significant pressure drop and forcing your pump to work harder, wasting energy. If it's too large, it will be difficult to control the flow precisely, and the valve may "chatter" when only slightly open, leading to premature wear.

What is the Flow Coefficient (Cv)?

The flow coefficient, or Cv, is a critical value that helps you size a valve correctly. It measures how much water (in US Gallons Per Minute) can pass through a fully open valve with a pressure drop of 1 psi. The formula is: Cv = Q × √(SG / ΔP) Where Q is the flow rate, SG is the specific gravity of the fluid (water is 1), and ΔP is the pressure drop. For your system, you calculate the required Cv and select a valve that matches it.

The Dangers of Incorrect Sizing

A properly sized valve operates smoothly and efficiently. An improperly sized one creates problems that can ripple through your entire system. It's a common mistake I see when clients are trying to cut costs by using a valve they already have in stock, even if it's not the right size. This short-term save often leads to long-term expenses.

| Sizing Issue | Consequence | How to Avoid |

|---|---|---|

| Undersized Valve | High pressure drop, reduced flow, potential for noise/cavitation. | Calculate the required Cv accurately for your system's flow rate. |

| Oversized Valve | Poor flow control, valve "chattering," wasted energy, higher initial cost. | Match the valve's Cv as closely as possible to the system's needs. |

What's the Best Material for Your Diaphragm Valve?

A valve's material looks fine on paper but fails quickly in your corrosive environment. This unexpected failure stops production. Choosing the right material is your first line of defense.

The best material depends entirely on your fluid's chemical composition and temperature. Common diaphragm material[^3]s like EPDM, PTFE, and NBR each offer specific resistances. The valve body and lining must also be compatible to prevent corrosion and ensure a long service life.

Material selection is where our expertise as a manufacturer really comes into play. We work with clients to understand their exact chemical application and recommend the perfect combination of body, lining, and diaphragm. For most industrial applications, a robust cast iron (CI) or ductile iron (DI) body is perfect. The real protection comes from the lining inside the valve and the diaphragm that isolates the fluid.

Choosing the Right Diaphragm Material

The diaphragm is the heart of the valve and does the hard work of both sealing and isolating the fluid. It needs to be flexible enough to open and close thousands of times but tough enough to resist the process fluid. We offer a range of materials to cover nearly any application.

Body and Lining Compatibility

The lining provides the primary barrier against corrosion and abrasion for the valve body. Our mechanically applied linings create a seamless, smooth surface that is superior to many other application methods. Whether you need a plastic lining like PFA for aggressive chemicals or a rubber lining[^5] like EPDM for water treatment, the choice is critical for the valve's longevity.

| Diaphragm Material | Best For | Typical Temperature Limit |

|---|---|---|

| EPDM | Water, wastewater, dilute acids/alkalis | ~120°C (250°F) |

| PTFE | Aggressive chemicals, acids, solvents, high purity | ~200°C (392°F) |

| NBR (Nitrile) | Oils, fuels, hydraulic fluids | ~100°C (212°F) |

| Butyl | Gases, steam, ketones | ~120°C (250°F) |

Should You Choose a Manual or Automated Diaphragm Valve?

You need precise, frequent valve adjustments, but your team can't always be there. This leads to inefficient processes. Automation could be the answer you are looking for.

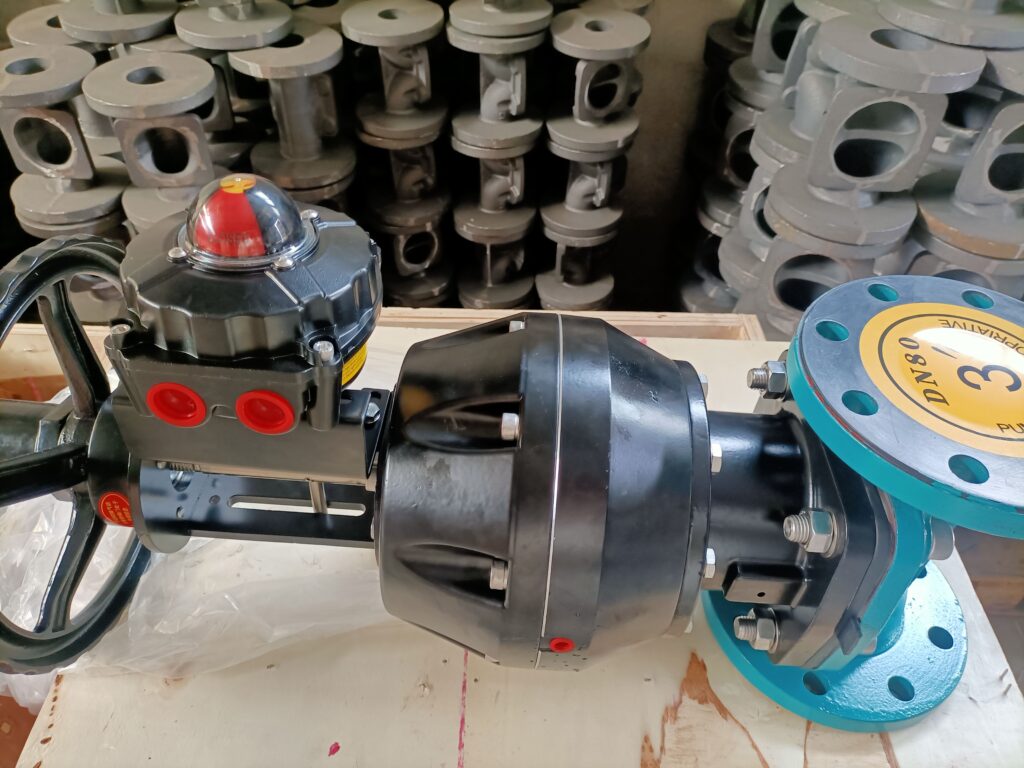

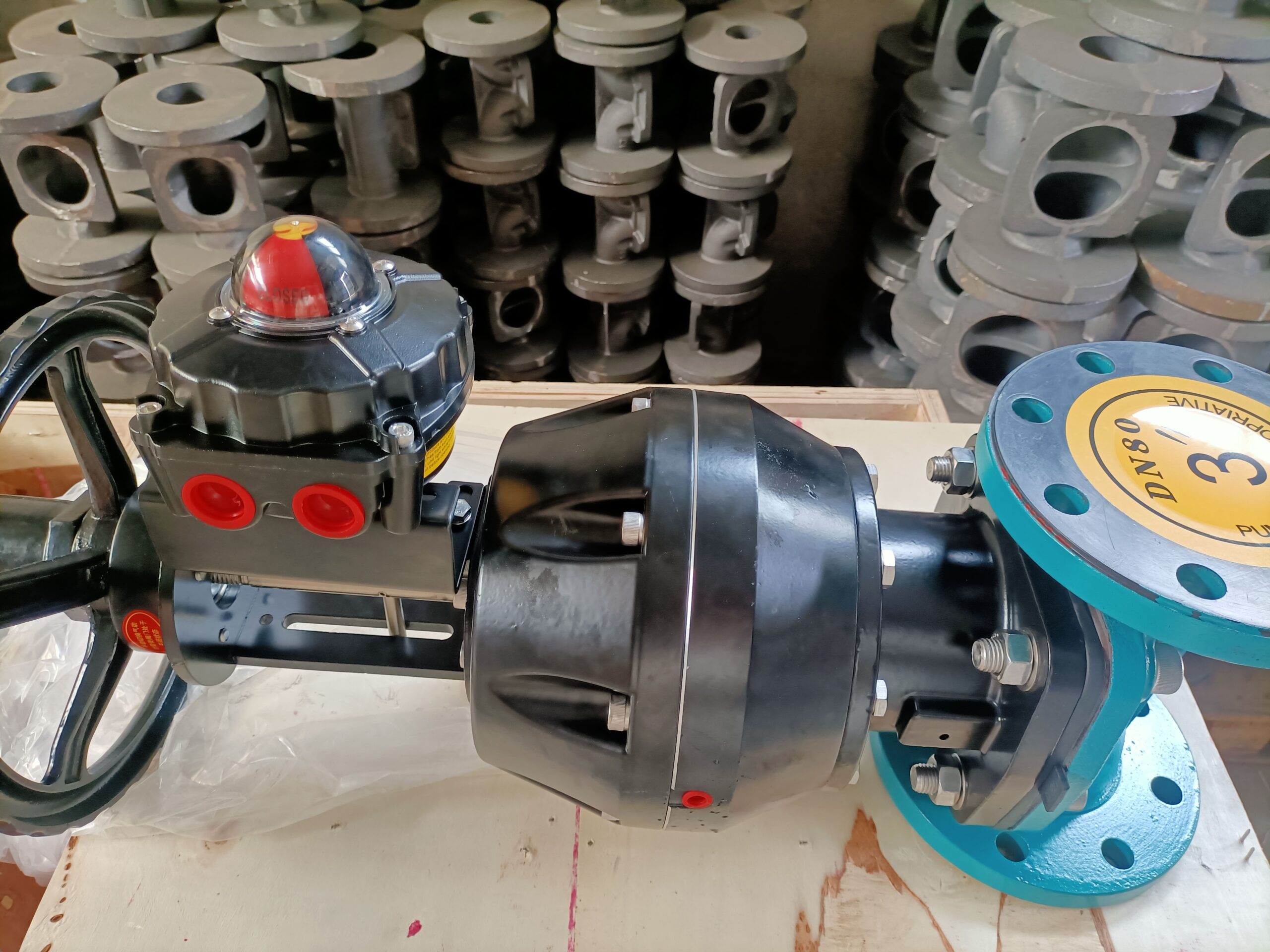

Choose manual operation for valves that are adjusted infrequently and don't require high precision. Opt for automated (pneumatic, electric) valves for frequent operation, remote control, or integration into a larger automated system for precise process control.

The decision between manual and automated operation often comes down to three factors: frequency of use, location, and the need for precision. I always ask my clients, "How often will someone need to turn this valve, and is it easy to get to?" The answer usually makes the choice clear.

When to Use Manual Valves

Manual valves, operated with a handwheel, are the simplest and most cost-effective option. They are perfect for on/off applications that don't change often, such as isolation for a piece of equipment that only needs to be taken offline for maintenance. They are reliable and easy to use, with a clear visual indicator of whether the valve is open or closed. If a valve only needs to be operated once a day or less, a manual valve is usually the right choice.

The Benefits of Automation

Pneumatic actuators, which we specialize in, use compressed air to open and close the valve. This is ideal for valves that need to be operated frequently or are part of an automated process, like a chemical dosing system in a wastewater plant. Automation allows for remote operation, precise control, and integration with a central control system (PLC). This improves process efficiency, enhances safety by removing operators from hazardous areas, and ensures consistent, repeatable results.

| Feature | Manual Operation (Handwheel) | Automated Operation (Pneumatic) |

|---|---|---|

| Cost | Lower initial cost. | Higher initial cost but lower long-term labor cost. |

| Control | Basic on/off and simple throttling. | Precise, repeatable control; can be modulated. |

| Best Use | Infrequent adjustments, simple isolation tasks. | Frequent adjustments, automated processes, remote locations. |

| Labor | Requires an on-site operator for every adjustment. | Can be operated remotely, reducing labor needs. |

What Should You Consider for Valve Maintenance and Installation?

A valve is installed in a tight spot, making repairs impossible without a full shutdown. This simple mistake creates a maintenance nightmare. Proper planning avoids this headache.

For easy maintenance, ensure the valve design allows for simple disassembly to clean or replace parts like the diaphragm. During installation, leave adequate space around the valve and its actuator for future inspection, servicing, and quick part replacement.

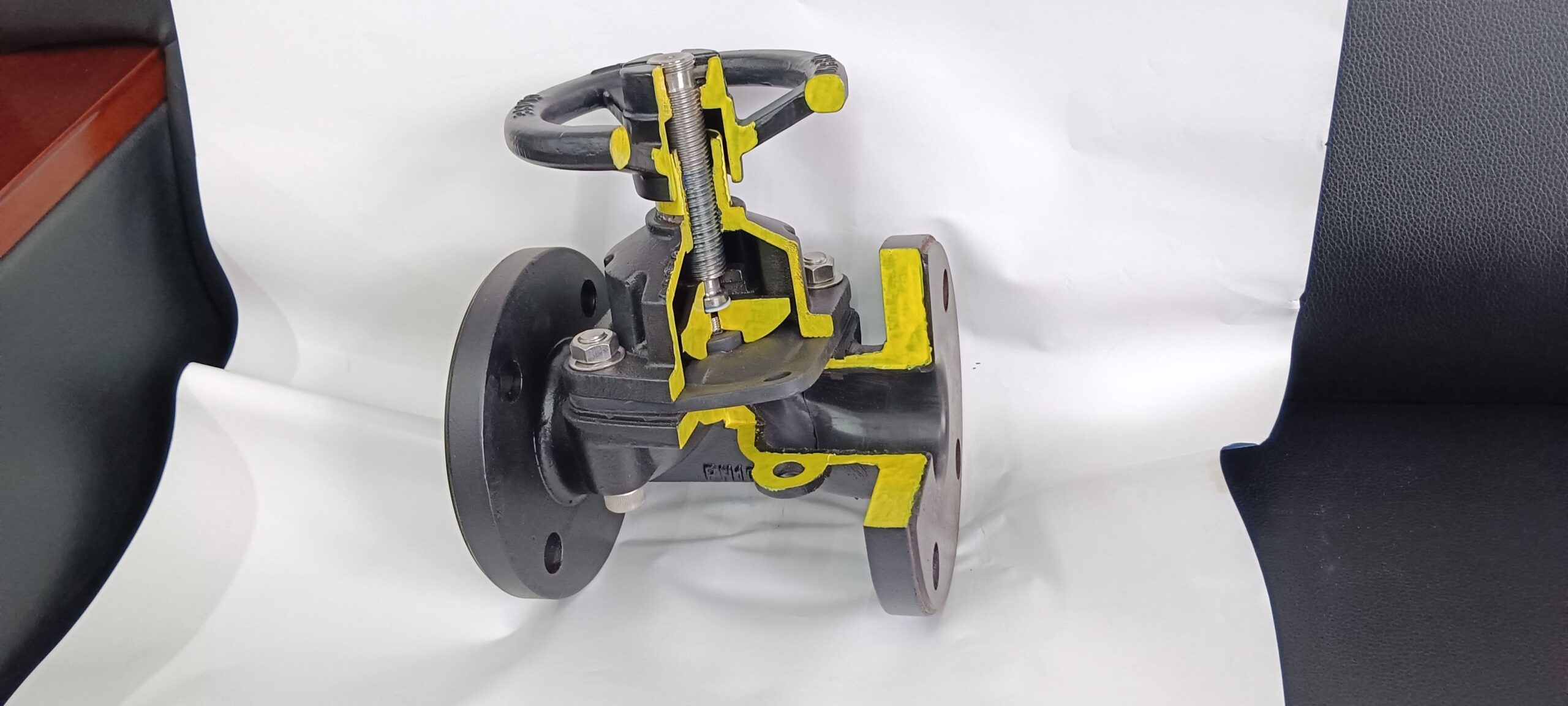

One of the great advantages of diaphragm valve[^1]s is their ease of maintenance. The diaphragm can be replaced without removing the valve body[^6] from the pipeline. This is a huge time-saver. However, this benefit is lost if the valve is installed without thinking about future access. I always remind my clients to think about the person who will have to service the valve in five years.

Designing for Easy Maintenance

A good diaphragm valve[^1] is designed for what we call "top-entry" service. This means all the working parts—the diaphragm and the actuator mechanism—can be accessed and replaced by simply removing the bonnet (the top part of the valve). This design feature is crucial for minimizing downtime. It's also why having a reliable supplier for spare parts is so important. We ensure that our clients can get replacement diaphragms and other parts quickly to keep their operations running smoothly.

Smart Installation Practices

When installing the valve, a little foresight goes a long way. Make sure there is enough clearance above the valve to remove the bonnet and enough room around it to use tools. If it's a manual valve, ensure the handwheel can be turned fully without hitting a wall or another pipe. For pneumatic valves, make sure the air lines can be connected and disconnected easily. Following the manufacturer's torque specifications[^7] for the flange bolts is also essential to create a good seal without damaging the valve.

| Installation Checklist |

|---|

| ✅ Is there enough clearance for the handwheel or actuator? |

| ✅ Can you access the bonnet bolts for diaphragm replacement? |

| ✅ Is the valve oriented correctly according to the flow direction arrow? |

| ✅ Are the flange bolts tightened evenly in a star pattern to prevent leaks? |

Why Must Your Diaphragm Valves Comply with Industry Standards?

Your valves don't meet local standards, causing your entire project to be rejected. This is a costly and embarrassing oversight. Compliance is not optional; it's essential for success.

Compliance with industry standards[^8] ensures your valve is safe, reliable, and interchangeable. Standards like BS5156 for dimensions and flange drilling standards[^9] (PN, ANSI) guarantee that the valve will fit your existing piping and meet required performance benchmarks.

For our clients, who are often international distributors, importers, and brands, standards are the universal language of quality and compatibility. When a valve complies with a recognized standard, it provides a guarantee. It tells the end-user that this product will fit, perform, and be safe as expected, no matter where it was manufactured.

Understanding Face-to-Face and Flange Standards

Two of the most important standards are for face-to-face dimension[^10]s and flange drilling. The "face-to-face" dimension (governed by standards like BS5156) is the length of the valve from the inlet flange to the outlet flange. A standard dimension ensures that if you need to replace a valve, the new one will fit in the exact same space without any need to cut or modify the pipe. Flange drilling standards (like ANSI for America, PN for Europe, or TABLE D for Australia) dictate the bolt hole pattern. Matching this ensures the valve will bolt up perfectly to the existing pipeline. We offer products that meet all these common international standards.

The Importance of Certification

For certain industries, like food, pharmaceutical, or drinking water, specific certifications are required to prove the materials are safe and non-toxic. While our core business is industrial applications with CI/DI bodies, we understand the critical role that certification plays. It's a formal verification that a product meets the highest levels of safety and quality, and it

[^1]: Diaphragm valves are crucial for controlling fluid flow in various industries, ensuring reliability and efficiency. [^2]: Choosing between manual and automated operation affects control precision and labor costs, impacting overall efficiency. [^3]: Selecting the right diaphragm material is essential for durability and compatibility with specific fluids. [^4]: The flow coefficient (Cv) is key to ensuring valves are properly sized for efficient fluid flow and energy use. [^5]: Rubber lining provides abrasion resistance and smooth flow, crucial for handling abrasive fluids. [^6]: Choosing the right valve body material is essential for durability and compatibility with process fluids. [^7]: Following torque specifications ensures a proper seal, preventing leaks and damage during installation. [^8]: Compliance with standards ensures safety, reliability, and compatibility, preventing costly project rejections. [^9]: Flange drilling standards ensure valves fit existing pipelines, preventing installation issues. [^10]: Standard face-to-face dimensions ensure easy valve replacement without modifying existing piping.