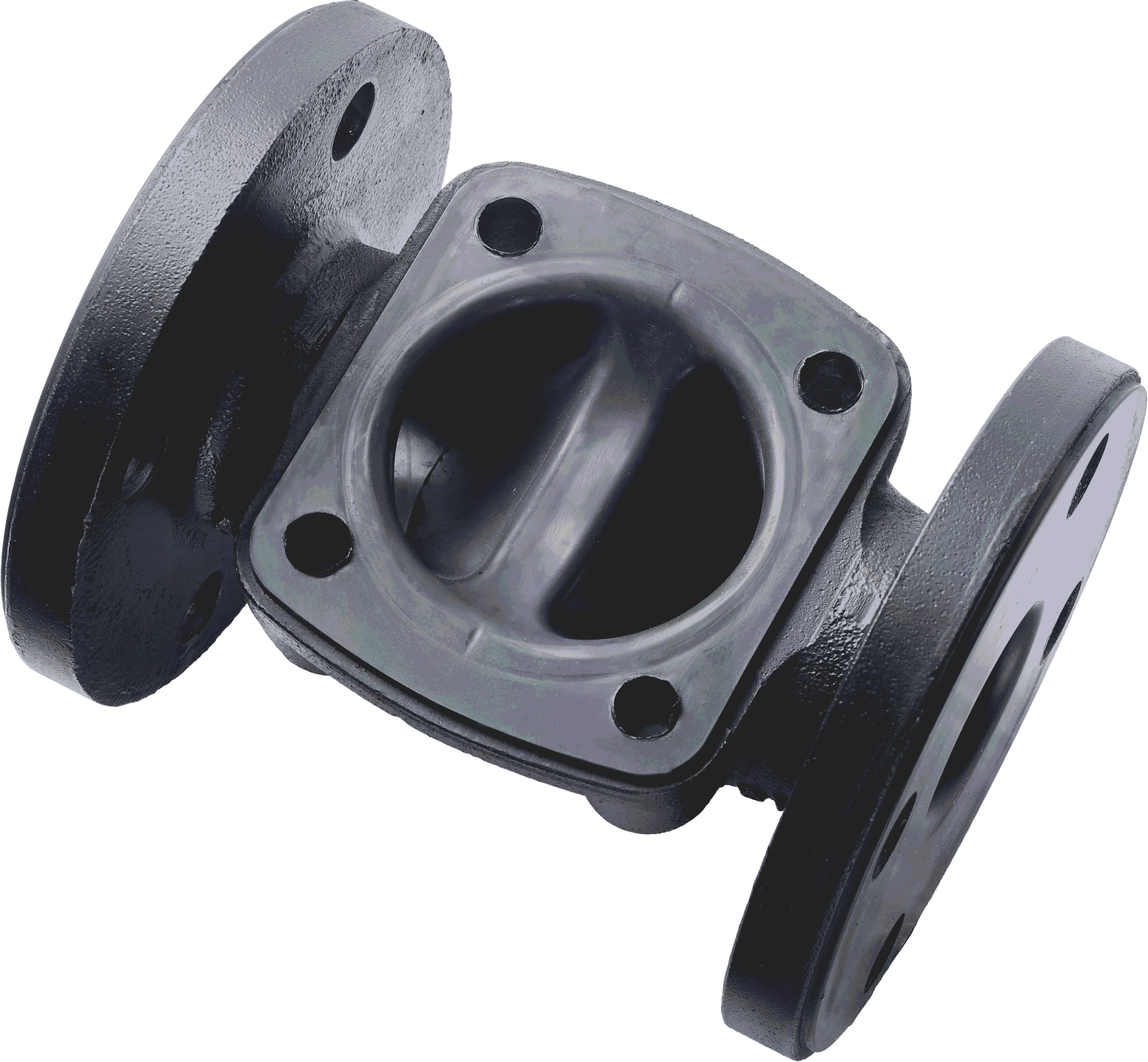

Are you concerned about the quality of hand-lined diaphragm valves? Their seams can fail, leading to costly corrosion. Mechanically lined valves offer a far more reliable, seamless solution.

Mechanically lined diaphragm valves use a machine vulcanization process[^1]. This creates a stronger, seamless bond between the lining and the valve body. It results in a smoother surface, better corrosion resistance[^2], and higher overall quality compared to traditional hand-lining methods.

Why is a Seamless Lining So Important for Your Valve's Lifespan?

Are hidden lining seams causing premature valve failure in your systems? These weak points can be a major headache. A seamless design eliminates this risk entirely, extending your equipment's life.

A seamless lining, created through mechanical application, has no joints or weak spots. This provides uniform protection against corrosive media. Unlike hand-lined valves, there are no seams to peel or fail, ensuring a longer, more reliable service life for the valve.

Let's dive deeper into this. The traditional method is hand-lining. Workers cut sheets of rubber, carefully fit them inside the valve body, and then vulcanize the seams. These seams are the valve's biggest weakness. Over time, corrosive media can attack these joints, causing the lining to peel away and the valve to fail. It's an unavoidable risk with this manual process. Our mechanical lining process is completely different. A machine applies a single, uniform layer of rubber or plastic inside the valve body. There are no cuts, no joints, and no seams. It's one solid, flawless protective barrier. This process ensures a much longer and more predictable service life for the valve.

| Feature | Hand-Lined | Mechanically Lined |

|---|---|---|

| Construction | Multiple pieces with seams | Single, seamless piece |

| Weak Points | Seams are prone to failure | No inherent weak points |

| Corrosion Path | Media can attack seams first | Uniform resistance across surface |

| Lifespan | Shorter, less predictable | Longer, more reliable |

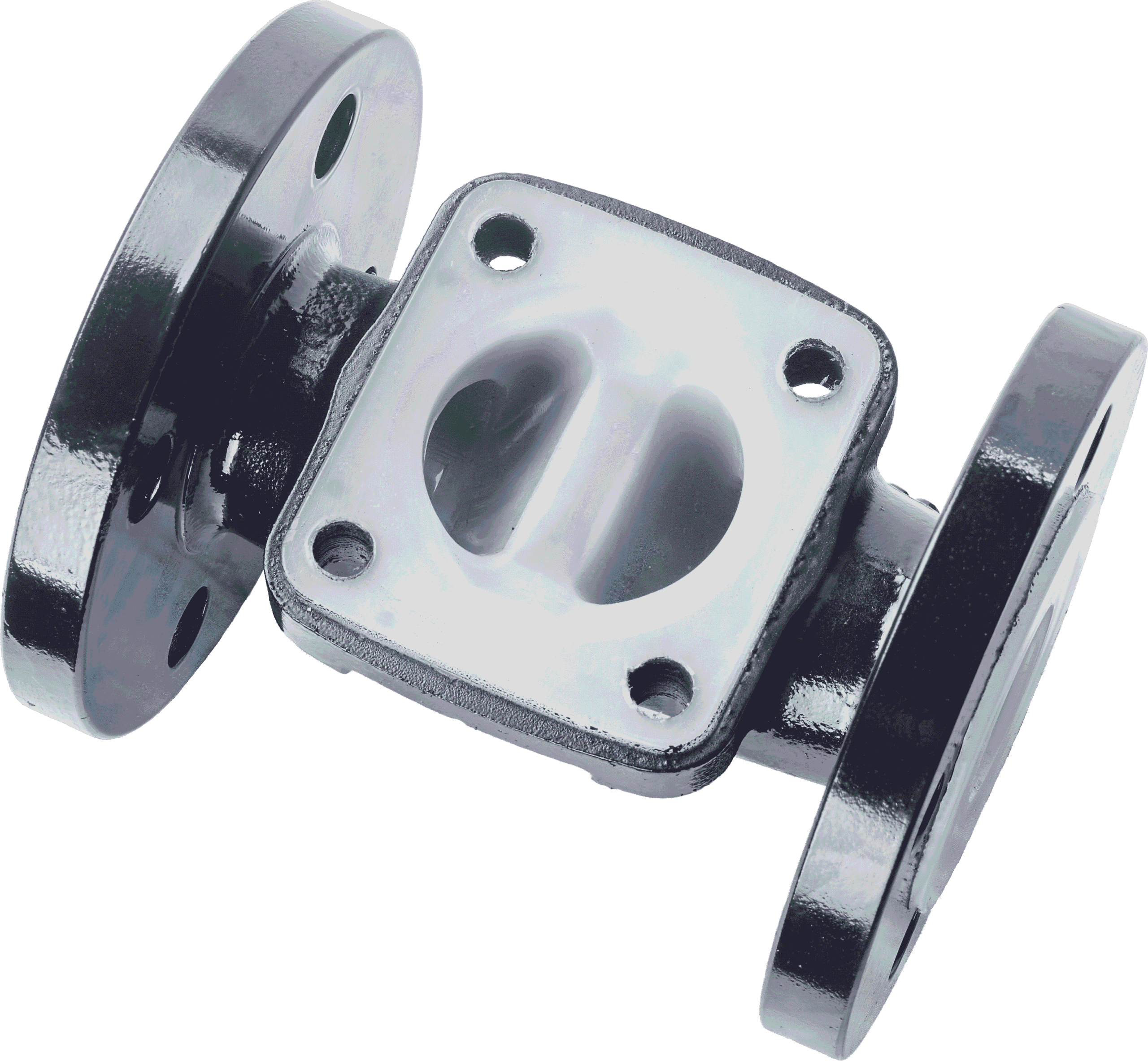

How Does the Manufacturing Process Affect Valve Quality and Performance?

Are you frustrated by rough surfaces and imperfections on your valves? This often starts with the casting process. Our advanced methods ensure a flawless foundation for a superior final product.

Our manufacturing process is critical to quality. We use resin-coated sand casting for a smoother valve body. Then, our mechanical lining process ensures perfect adhesion and a flawless internal surface. This combination results in better flow, higher performance, and a visually superior product.

Quality begins with the foundation. We start with a superior casting process called resin-coated sand casting. This method produces valve bodies with far fewer imperfections and a much smoother surface finish compared to traditional sand casting. A better base allows for a better lining application. Next, we move to the lining itself. Our mechanical vulcanization process creates an incredibly strong bond between the lining and the metal. It’s not just glued on; it’s fused together under intense heat and pressure. This prevents the lining from delaminating, even under harsh conditions. This smooth, perfectly bonded lining also complements our full-diameter internal design. The flow path is completely unobstructed, which lowers flow resistance and allows for a much higher flow rate. This makes our valves ideal for tough applications involving coarse fibers or suspended particles, like in wastewater treatment or mining.

Is Investing in Mechanically Lined Valves Worth It for Your Brand?

Does your current valve supplier's quality reflect your own brand's standards? Inconsistent products can damage your reputation. Choosing a premium valve is a direct investment in your brand's image.

Absolutely. If you care about quality, reliability, and your brand's reputation, mechanically lined valves are the superior choice. They offer a longer lifespan, better performance, and a premium appearance that aligns with high-quality brands. It is a product you can proudly stand behind.

I want to share a quick story. We saw the limitations of hand-lining years ago. We knew there had to be a better way. It wasn't easy. We spent years on research and development, perfecting our molds and processes to achieve a flawless mechanical lining. In fact, some major international brands tried to develop this technology and failed. But about six years ago, our engineering team finally broke through. Our products succeeded, and they have been proven in the field with excellent feedback from our clients. This effort is what separates a standard valve from a premium one. It's not just a component; it's a piece of engineering that reflects a deep commitment to quality. So, who is this for?

- Choose Hand-Lined If: Budget is the only concern and minor inconsistencies are acceptable for the application.

- Choose Mechanically Lined If: Your brand image, long-term reliability, and superior performance are your top priorities.

If you are an importer, distributor, or a brand that wants to offer customers a superior product, our valves are the best choice.

Conclusion

For those who prioritize brand image and long-term reliability, our mechanically lined diaphragm valves are the best choice. They deliver the quality and performance your customers expect.

[^1]: Learn how machine vulcanization enhances the durability and reliability of diaphragm valves. [^2]: Discover key factors that influence corrosion resistance and how to choose the best valves.