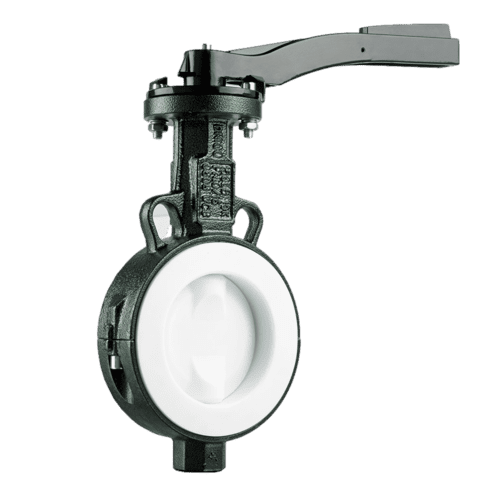

The valve seat is a detachable part inside the valve. Its main function is to support the valve core to be fully closed or fully closed, and to form a sealing pair. Under normal circumstances, the diameter of the valve seat is the size of the valve. The butterfly valve seat has a wide range of materials, but the commonly used materials include soft-seal EPDM, nitrile rubber (NBR), polytetrafluoroethylene (PTFE), and metal seated alloy materials. kind. Let’s introduce one by one

EPDM

Compared with other general-purpose rubbers, EPDM rubber has great advantages.

①The cost performance is very high. Among the commonly used rubbers, EPDM has the lightest raw rubber density and can be filled in a large amount, reducing the cost of the rubber.

②EPDM material is resistant to aging, can withstand sun exposure, heat resistance, moisture resistance, radiation resistance, and is suitable for weak acid and weak alkali media. Good insulation properties.

③The applicable temperature range can be as low as -40℃, and it can be used for a long time under the temperature condition of 120℃.

NBR

Oil resistance, heat resistance, abrasion resistance and good water resistance, air tightness and excellent bonding properties. It is widely used in petroleum pipelines. The disadvantage is that it is not resistant to low temperature, ozone, poor insulation performance, and general elasticity.

PTFE

A fluoroplastic, this material has strong resistance to acids, alkalis, and various organic solvents. At the same time, the material is resistant to high temperatures and can be used continuously at 260°C, and the maximum use temperature can reach 290-320°C. The emergence of PTFE has successfully solved many problems in the chemical, petroleum, pharmaceutical and other industries.

Metal seated(hard alloy)

The material of the metal seated valve seat has very good characteristics of high temperature and high pressure resistance, corrosion resistance, wear resistance, etc., which makes up for the defects of soft seal materials that are not resistant to high temperature and high pressure, but hard seated materials require high processing technology. , The only disadvantage of the metal hard-seal valve seat is that the sealing performance is not that good, and it may leak after a long time of operation.