Leaks and corrosion from standard valves can be a nightmare, causing costly downtime and safety hazards. Diaphragm valves[^1] offer a unique, isolated design to solve this problem effectively.

A diaphragm valve is a special type of valve that uses a flexible diaphragm[^2] to control fluid flow. This diaphragm acts as a complete barrier, isolating the fluid from the valve's moving parts. This design prevents leaks, contamination, and corrosion, making it perfect for tough industrial applications.

That's the basic idea, but there is so much more to it. I've been in the valve manufacturing business for years, and I know that the details make all the difference. To really understand if a diaphragm valve is the right choice for your needs, we need to look closer at the different types, their structures, and the materials they are made from. Let's break it down together so you can make an informed decision.

How are diaphragm valves operated?

Choosing the wrong valve control can lead to major inefficiency in your plant. Manual control might be too slow for your process, while full automation can seem complex.

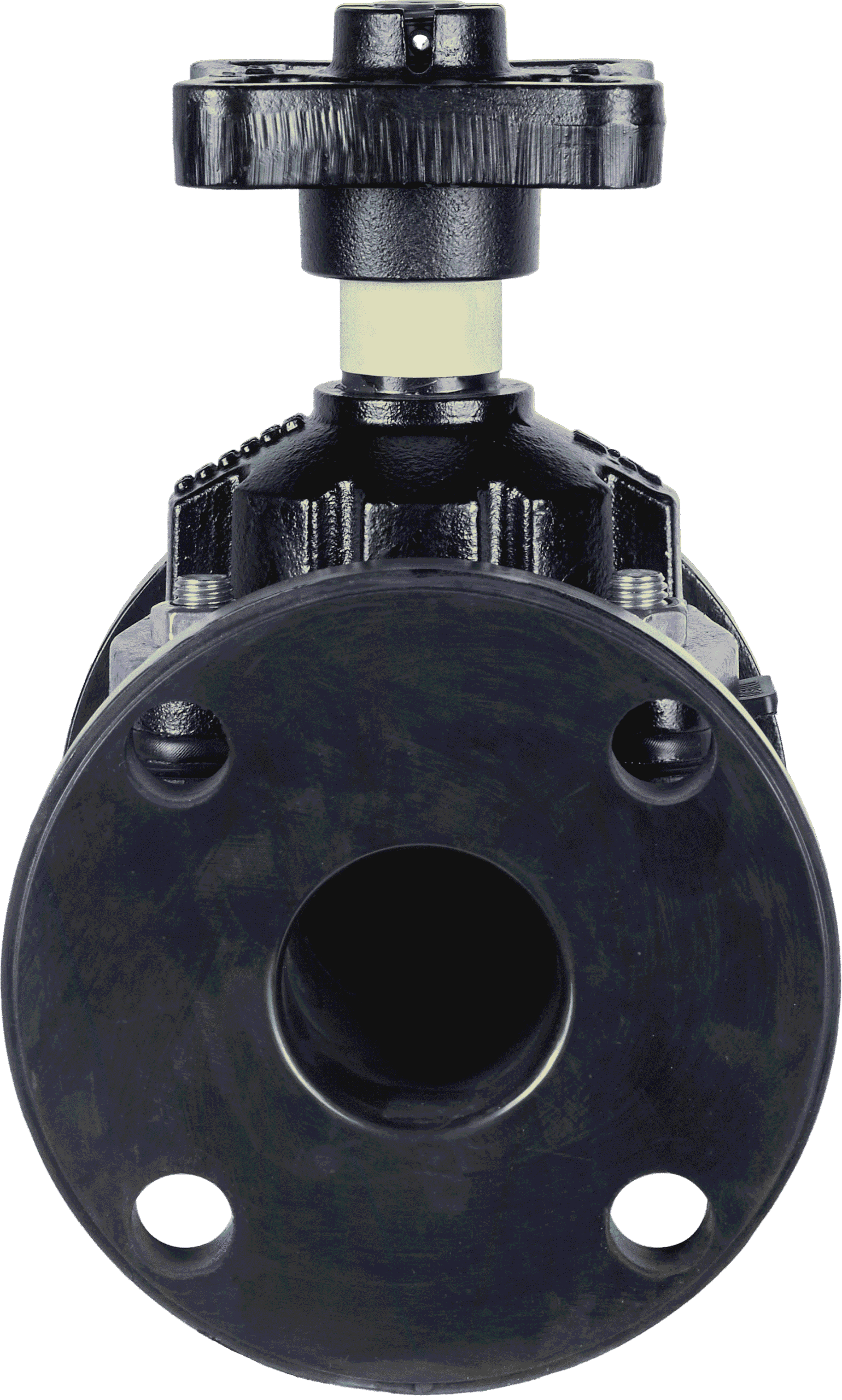

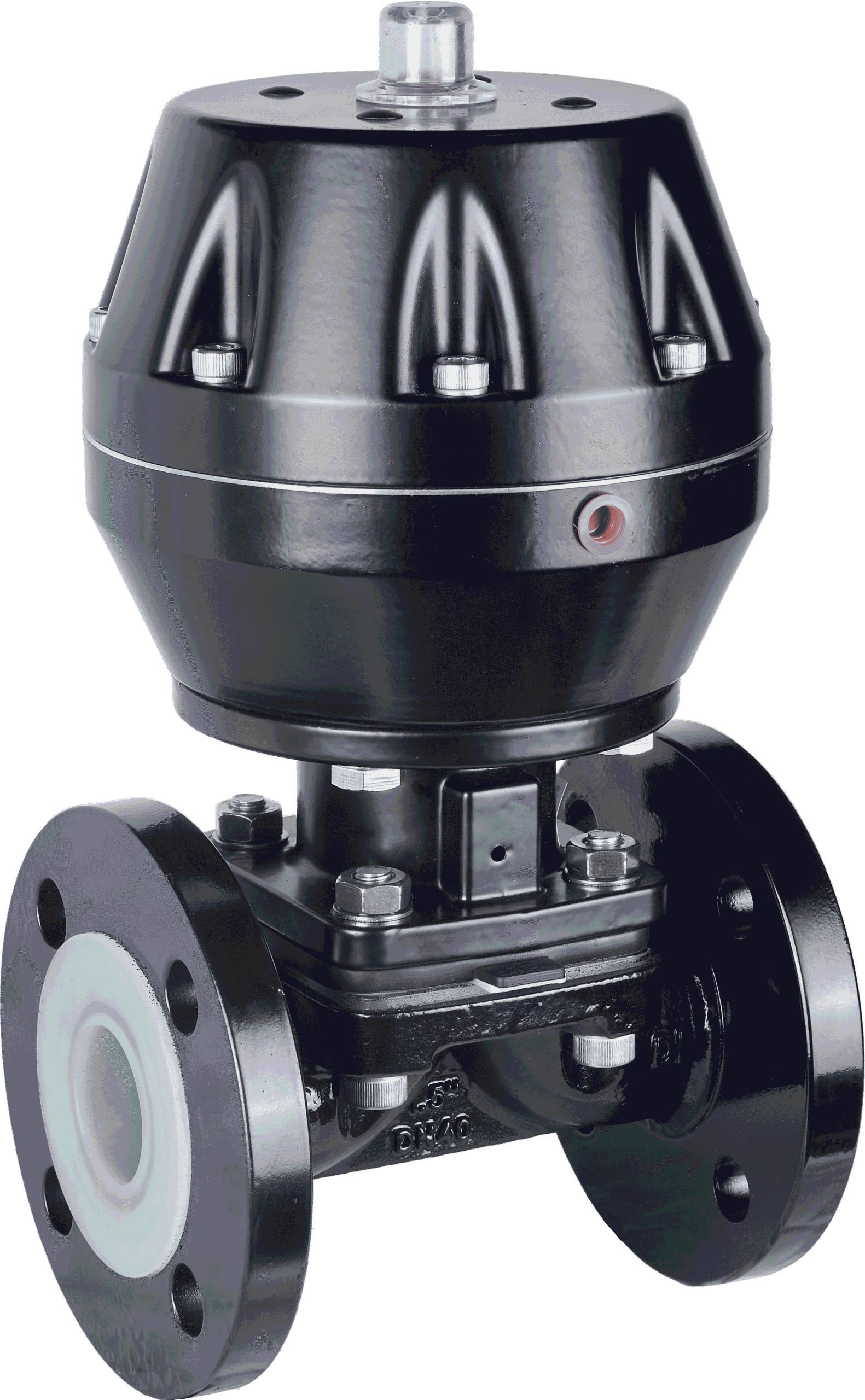

Diaphragm valves[^1] are typically operated in two ways: manually or pneumatically. Manual valves use a simple handwheel for direct control. Pneumatic valves use compressed air to open and close the valve automatically, making them ideal for automated systems and remote operations.

When you are deciding on a valve, the first question is often about control. Do you need an operator to turn a wheel, or should the valve work on its own? This choice between manual and pneumatic operation is critical. In my experience, manual valves are the go-to for smaller setups or applications where adjustments are not needed very often. I remember a client with a small chemical dosing system who needed a foolproof solution. The manual valve was perfect because it gave them precise control without needing a complex air supply system. On the other hand, pneumatic valves[^3] are the heart of large-scale automation. They use an air-powered actuator to open and close the valve quickly and reliably. We supply thousands of these to power plants and wastewater treatment facilities where automated control is essential for efficiency and safety. They can even be set up to fail-open or fail-close, which is a crucial safety feature.

| Feature | Manual Diaphragm Valve | Pneumatic Diaphragm Valve |

|---|---|---|

| Operation | Handwheel | Compressed Air Actuator |

| Best For | Local control, infrequent adjustments | Automated systems, remote control |

| Speed | Slower, depends on operator | Fast, consistent operation |

| Complexity | Very simple and reliable | Requires air supply and control system |

| Cost | Lower initial cost | Higher initial cost |

What are the different structural designs of diaphragm valves?

Not all flow paths are created equal. Some valves can easily cause clogging when you're dealing with slurries or thick fluids, leading to serious production stops.

Diaphragm valves[^1] come in two main structural types: weir-type[^4] and straight-through. The weir-type[^4] has a raised "weir" in the valve body for the diaphragm to seal against, offering precise control. The straight-through design[^5] provides an unobstructed flow path, ideal for thick slurries.

The internal design of the valve body completely changes how it performs. The weir-type[^4] is the most common design you will see. It has a small, raised ridge—the weir—across the flow path. The diaphragm only has to travel a short distance to press down on this weir and stop the flow. This short travel distance puts less stress on the diaphragm, which means it lasts longer. I've seen these used extensively in chemical plants for dosing applications where very precise flow control is needed. However, that weir can be a problem if your fluid has solids in it. That’s where the straight-through design[^5] comes in. It has a completely open, smooth flow path with no obstructions. A client of ours in the mining industry needed a valve for an abrasive ore slurry line. A weir-type[^4] would have clogged instantly. The straight-through design[^5] was the only choice, and it has worked perfectly for them for years. It allows thick, heavy materials to pass through without any issues.

| Feature | Weir-Type Diaphragm Valve | Straight-Through Diaphragm Valve |

|---|---|---|

| Flow Path | Raised weir inside the body | Unobstructed, smooth path |

| Best For | Clean fluids, throttling, precise control | Slurries, sludges, viscous fluids |

| Diaphragm Life | Generally longer due to shorter travel | Can be shorter due to more flexing |

| Sealing | Excellent, tight shut-off | Very good, reliable shut-off |

| Clogging Risk | Higher risk with solids | Very low risk of clogging |

What lining materials are used in diaphragm valves?

Aggressive chemicals can destroy standard valves in a matter of weeks. This leads to costly replacements, production downtime, and even dangerous leaks on the factory floor.

Diaphragm valves[^1] use either rubber or plastic linings to protect the valve body from corrosive or abrasive media. Rubber linings like EPDM[^6] are flexible and wear-resistant. Plastic linings like PFA and PTFE[^7] offer the highest level of chemical and temperature resistance.

The real magic of a diaphragm valve is its ability to handle incredibly harsh materials. This is possible because the valve body, which is usually made of cost-effective cast iron or ductile iron, is protected by a high-performance lining. The choice of lining depends entirely on the fluid you are handling. For general industrial applications like wastewater treatment, rubber linings are fantastic. We supply a lot of EPDM[^6]-lined valves for these plants. It's a workhorse material that handles a mix of chemicals and solids perfectly without a high price tag. For the most aggressive chemicals, you need to step up to plastic linings. Materials like PTFE[^7] and PFA are resistant to almost everything, including strong acids and solvents. At our factory, we use a mechanically applied lining process. This creates a perfectly seamless and smooth surface inside the valve. It's visually superior and performs more reliably than other methods, which is a key reason why international brands choose us for their OEM needs[^8].

| Lining Material | Common Use Cases | Key Advantages |

|---|---|---|

| EPDM[^6] (Rubber) | Water treatment, dilute acids/alkalis | Excellent weather resistance, good for water |

| NBR (Rubber) | Oils, fuels, solvents | Great resistance to oils and hydrocarbons |

| PTFE[^7] (Plastic) | Strong acids, aggressive chemicals | Nearly universal chemical resistance, high temp |

| PFA (Plastic) | High-purity, highly corrosive media | Similar to PTFE[^7] but with better flexibility |

Conclusion

Diaphragm valves[^1] provide a reliable, leak-proof solution for tough industrial fluids. Understanding their types and linings is key to choosing the right valve for your specific application.

[^1]: Explore this link to understand the unique features and benefits of diaphragm valves in industrial applications. [^2]: Learn about the role of the flexible diaphragm in controlling fluid flow and preventing leaks. [^3]: Understand the advantages of pneumatic valves for automated systems and remote operations. [^4]: Explore the features and applications of weir-type diaphragm valves for precise control. [^5]: Learn how straight-through designs facilitate unobstructed flow paths for thick fluids. [^6]: Discover the benefits of EPDM linings in diaphragm valves for water treatment and chemical handling. [^7]: Explore the chemical resistance properties of PTFE and its applications in harsh environments. [^8]: Discover how diaphragm valves meet the specific requirements of original equipment manufacturers.