Dealing with leaking valves[^1] and corroded parts[^2] is a nightmare for plant managers. You need a solution that handles tough chemicals without failing constantly and causing expensive downtime.

Diaphragm valves[^3] use a flexible membrane to seal liquids off from the valve mechanism. This isolation prevents leaks and corrosion. They feature lined bodies for chemical resistance[^4] and replaceable diaphragms[^5], making them the most cost-effective choice for handling aggressive fluids and slurries.

I have seen many factories struggle with the wrong valves. They use expensive alloys, but they still face leaks. This article explains why the diaphragm valve is the best tool for the job.

How Does the Isolation Mechanism Prevent Leaks Effectively?

Leaks often happen when fluid attacks the valve stem packing. This causes safety risks that you cannot afford in your daily industrial operations.

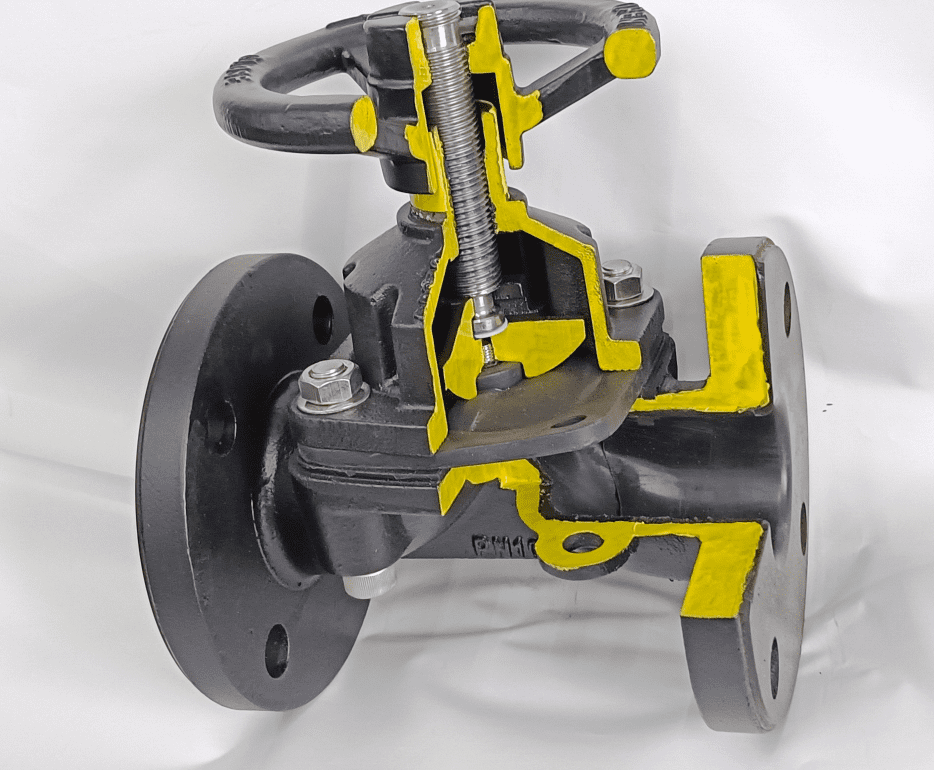

The diaphragm creates a physical barrier between the flow and the actuator. This means the corrosive liquid never touches the metal moving parts. It stops stem leakage[^6] completely and protects the operating mechanism from damage.

I want to explain this isolation feature clearly. In a standard gate or globe valve, the liquid touches the stem. The stem moves up and down. Eventually, the seal around the stem wears out. Then, the valve leaks. A diaphragm valve is different. The diaphragm is a flexible sheet. It sits between the liquid and the metal stem. When we operate the valve, the compressor pushes the diaphragm down.

This design is brilliant for harsh environments. The liquid only touches the inner lining of the body and the diaphragm itself. It never touches the screw, the compressor, or the bonnet. This is my main insight on why these valves last longer. The medium is totally separated from the valve axis. You do not need to worry about the stem rusting. You do not need to worry about the actuator getting jammed by sludge. This design simplifies the entire structure. It makes the valve incredibly reliable for dangerous chemicals.

| Feature | Standard Valve | Diaphragm Valve |

|---|---|---|

| Fluid Contact | Touches Stem & Seat | Touches Lining & Diaphragm Only |

| Leak Path | Stem Packing | None (Hermetic Seal) |

| Maintenance | Complex | Simple Diaphragm Change |

Why Are Valve Body Linings Essential for Corrosive Media?

Cast iron bodies are strong but they rust easily. You need the strength of iron mixed with the chemical resistance[^4] of high-grade plastic or rubber.

We line the interior of our cast iron and ductile iron valves with materials like PFA, PTFE, or EPDM rubber. This lining acts as a shield. It ensures the metal body never comes into direct contact with the acid or alkali.

We manufacture valve bodies using Cast Iron (CI) or Ductile Iron (DI). These metals are strong. They are also affordable. However, they cannot resist strong acids like sulfuric acid or harsh alkalis. This is where the lining becomes important. The lining is a protective skin inside the valve. We use various materials for this lining. We use plastics like PFA, PTFE, and ETFE. We also use rubbers like EPDM, NBR, and Soft Natural Rubber.

The lining covers every part of the metal that touches the fluid. It transforms a standard iron valve into a corrosion-resistant tool. This is much cheaper than making the whole valve out of stainless steel. In our factory, we use a mechanical application method for linings. This makes the lining seamless. It is smoother than other brands. A smoother surface means less friction. It also means less chance for the lining to peel off. This combination of a strong metal shell and a chemical-resistant liner is the perfect solution for heavy industry.

How Can Replaceable Diaphragms Significantly Reduce Your Operating Costs?

Replacing an entire valve is expensive and takes a long time. You want a system where you only fix the part that actually wears out.

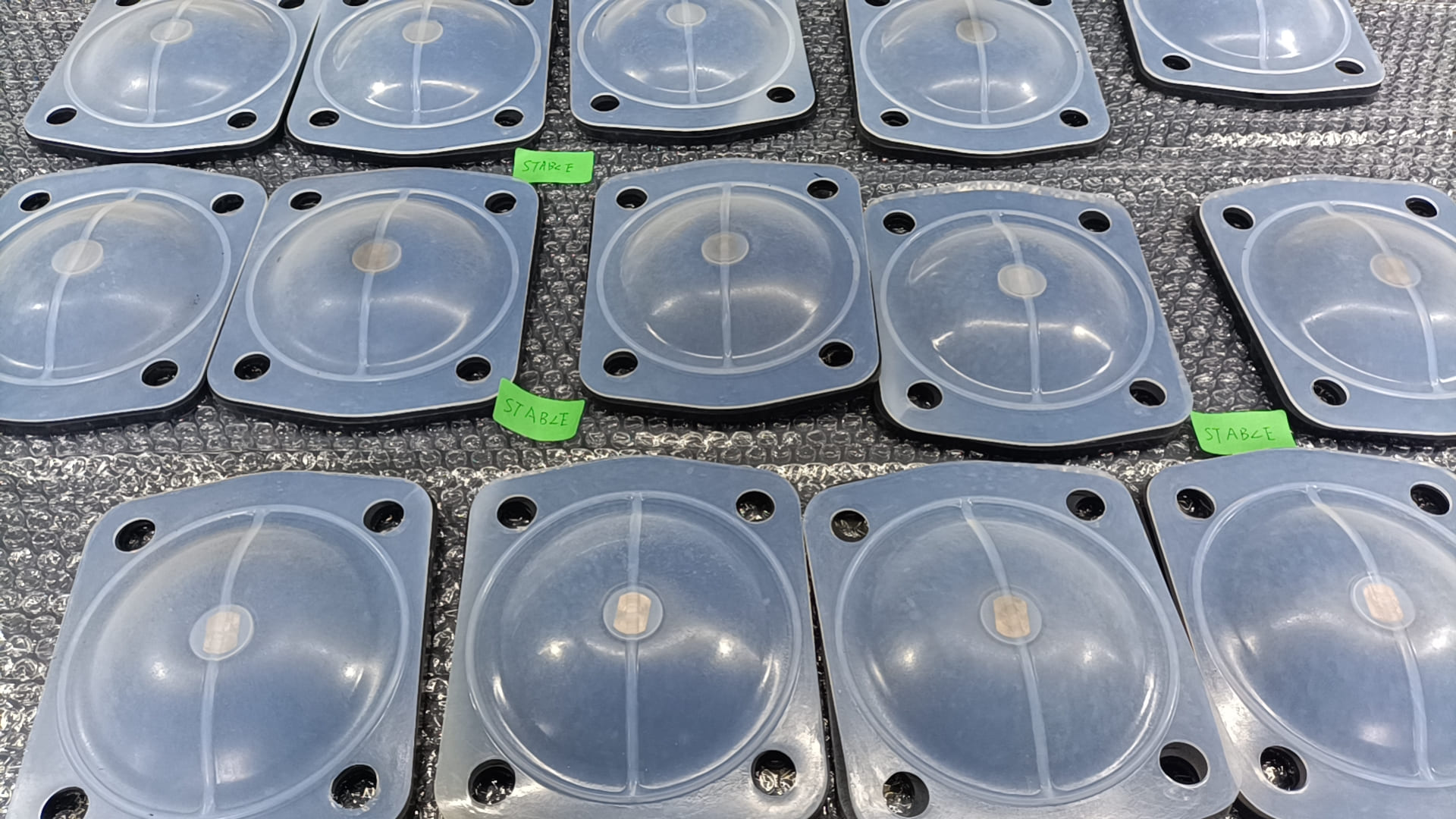

The diaphragm is the only part that takes damage over time. When it wears out, you simply unbolt the bonnet and put in a new sheet. You do not need to remove the whole valve body from the pipeline.

Every valve will wear out eventually. However, the diaphragm valve handles this problem in a smart way. The diaphragm is a "sacrificial" part. It takes all the abuse from the chemicals and the opening cycles. The metal body remains safe because of the lining. When the diaphragm finally corrodes or cracks, the valve is not dead. You do not need to buy a new valve. You just buy a new diaphragm.

This process is very fast. You loosen the bolts on the top. You lift the bonnet. You take out the old rubber or plastic sheet. You put a new one in. Then you tighten the bolts. The valve is now as good as new. This extends the lifespan of your equipment significantly. It reduces your long-term costs. My insight is that this modular design is the biggest advantage for B2B buyers. You can keep a stock of spare diaphragms. This is much cheaper than stocking whole valves. It keeps your plant running with minimal interruption.

What Manufacturing Processes Result in the Best Quality Valve Bodies?

Poor casting leads to pinholes and lining failure. You need valves that look good and perform perfectly from the inside out to ensure safety.

We use resin-coated sand casting[^7] for our valve bodies. This technique creates a much smoother surface than traditional methods. A smoother body means the lining adheres better and the valve lasts longer without defects.

I want to talk about how we make these valves. Many manufacturers in China use old casting methods. The surface comes out rough. It has many small holes. This is bad for the lining. If the metal is rough, the rubber lining might not stick well. It might bubble or peel. We do things differently. We use the resin-coated sand casting process. This is a more advanced technique. It creates a very smooth surface on the Cast Iron or Ductile Iron body.

We also use all-new molds. This ensures the shape is precise every time. Our design aligns with international aesthetics. It looks professional and clean. Because the metal body is smooth, our mechanical lining fits perfectly. There are no gaps. There are no imperfections. This results in a higher quality product. It looks better than valves from typical Indian factories. It also performs better. Distributors love this because the product looks premium, but the price is still competitive.

Which Industries Benefit Most from Installing Diaphragm Valves?

Not every valve works for every job. You must know exactly where these valves perform best to avoid system failures and wasted budget.

These valves are perfect for water treatment, chemical dosing, and power plants. They handle dirty slurries and clean chemicals equally well. Their design prevents clogging, making them ideal for wastewater and desulfurization systems.

We see these valves used in very specific places. They are the top choice for the Chemical Industry. They move acids and alkalis safely. The lining stops the corrosion. They are also huge in Power Plants. Thermal plants use them for desulfurization (FGD). This involves limestone slurry. Slurry is abrasive. It acts like sandpaper. But our rubber linings resist this wear. The straight flow path helps too. It prevents the slurry from clogging the valve.

Wastewater treatment is another big area. Plants use them for dosing chemicals like Sodium Hypochlorite. They also use them for sludge lines. The valve seals tight. It does not leak. This keeps the environment clean. We also serve the Metallurgy and Mining sectors. These places deal with heavy ore slurries. The diaphragm valve is tough enough to handle it. Whether you need a manual valve or a pneumatic one for automation, this design fits these industries perfectly.

| Industry | Key Challenge | Diaphragm Valve Solution |

|---|---|---|

| Chemical | Corrosive Acids | PTFE/PFA Linings |

| Power Plants | Abrasive Slurry | Rubber Linings & Smooth Flow |

| Water Treatment | Chemical Dosing | Precision & Leak Prevention |

Conclusion

Diaphragm valves[^3] isolate fluid, resist corrosion with linings, and lower costs through easy maintenance. We provide high-quality, customized solutions for your business needs.

[^1]: Explore solutions to prevent leaks in industrial valves, ensuring safety and reducing costly downtime. [^2]: Understand the causes of corrosion in valve parts to implement effective prevention strategies. [^3]: Learn why diaphragm valves are ideal for managing aggressive fluids, offering reliability and cost-effectiveness. [^4]: Discover how diaphragm valves offer chemical resistance, protecting against harsh industrial chemicals. [^5]: Find out how replaceable diaphragms can reduce maintenance costs and extend valve lifespan. [^6]: Learn about stem leakage in valves and methods to prevent it, ensuring operational safety. [^7]: Discover how resin-coated sand casting enhances valve quality by providing smoother surfaces and better lining adhesion.