Choosing the right diaphragm valve[^1] can feel complicated. Making the wrong choice leads to inefficiency, clogging, or leaks. It’s a simple decision that has a big impact on your operations.

The best choice depends on your media and sealing needs. Weir-type valves have a raised internal weir for superior, bubble-tight sealing, ideal for clean or moderately viscous fluids. Straight-through valves offer an unobstructed flow path, perfect for abrasive slurries and high-flow applications.

That's the quick answer, but the details are what really matter for your specific application. As a manufacturer, I've seen how picking the right valve design from the start saves our clients time, money, and a lot of headaches down the road. Let's break down the structural differences, performance characteristics, and ideal use cases for each type to help you make the perfect choice for your business or your customers.

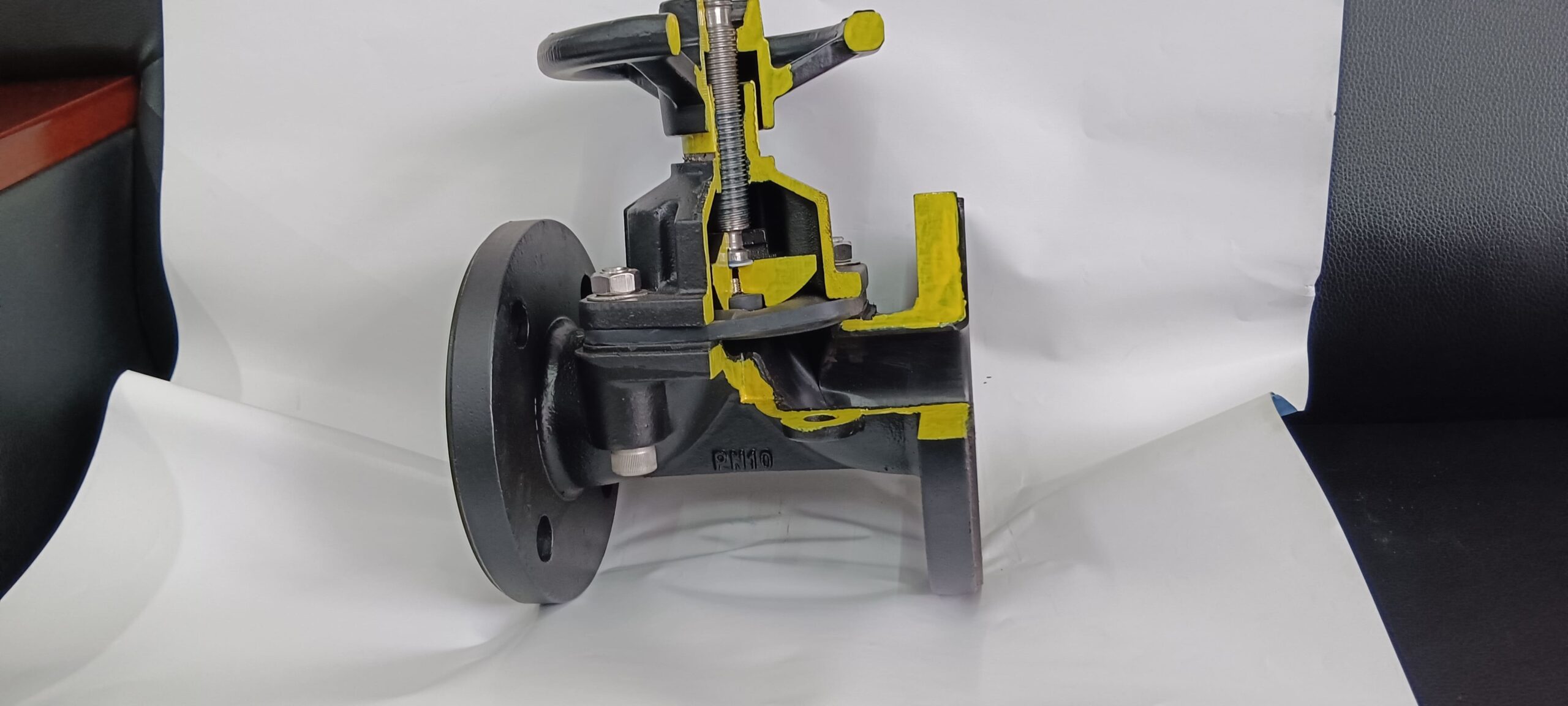

How Do Their Internal Structures Really Differ?

From the outside, these valves can look very similar. But not knowing the internal design can lead you to pick a valve that’s completely wrong for your fluid flow.

The core structural difference is the flow path. A weir-type valve has a raised ridge (the weir) inside the body that the diaphragm closes onto. A straight-through valve has a smooth, completely unobstructed, pipe-like flow path.

Let's dive deeper into what this means for the valve's mechanics. In a weir-type valve, the diaphragm only needs to travel a short distance to press down on the top of the weir and create a seal. This short stroke reduces stress on the diaphragm, often leading to a longer service life. The weir itself creates a very defined, smaller sealing area, which helps achieve a tight shut-off.

On the other hand, the straight-through valve is designed for minimal obstruction. When open, it’s like a straight piece of pipe. To close, the diaphragm must travel a much longer distance to reach the bottom of the valve body and seal against the inner wall. This full-bore design is what gives it its unique performance advantages.

Here's a simple breakdown:

| Feature | Weir-Type Diaphragm Valve | Straight-Through Diaphragm Valve |

|---|---|---|

| Flow Path | Obstructed by a raised weir | Unobstructed, straight-through |

| Sealing Point | Diaphragm seals on top of the weir | Diaphragm seals on the bottom wall |

| Diaphragm Stroke | Short | Long |

| Internal Profile | Contoured | Smooth, pipe-like |

Which One Performs Better for My Needs?

You need a valve that performs reliably, but "better" depends entirely on your specific goals. Are you prioritizing a perfect seal, or do you need maximum flow with minimal resistance?

Weir-type valves offer superior sealing and better throttling control but at the cost of higher flow resistance. Straight-through valves provide maximum flow capacity and low pressure drop, making them excellent for slurries but with less precise control.

Let's look at performance head-to-head. For flow rate and pressure drop, the straight-through valve is the clear winner. Its unobstructed path allows media to pass through with very little resistance, which is critical in systems where you need to maintain pressure and high flow. The weir-type, by its very design, creates turbulence and a higher pressure drop as the fluid has to go up and over the weir.

However, when it comes to sealing integrity, the weir-type is superior. The short stroke and small, defined sealing area allow it to create a bubble-tight shut-off. This makes it the go-to choice for applications where you absolutely cannot have any leakage, such as in chemical dosing. The straight-through valve provides a good seal, but the longer diaphragm travel and larger sealing surface make it slightly less absolute.

This table summarizes the performance trade-offs:

| Performance Metric | Weir-Type Diaphragm Valve | Straight-Through Diaphragm Valve |

|---|---|---|

| Flow Rate | Lower | Higher |

| Pressure Drop | Higher | Lower |

| Sealing Integrity | Excellent, bubble-tight | Good |

| Throttling Control | Good | Poor to Fair |

Where Should I Use Each Type of Valve?

You know the structure and performance, but where do you actually install each type for the best results? Using the wrong valve in a critical application can cause system failure or constant maintenance.

Use weir-type valves[^2] for clean or slightly particulate fluids that require tight shut-off, like in chemical processing or water treatment. Use straight-through valves[^3] for abrasive slurries or viscous media where maximum flow and clog resistance are critical.

I remember a client who was having constant clogging issues in their mining slurry[^4] line. They were using a weir-type valve, and the solids kept settling behind the weir, blocking flow. Once we supplied them with our straight-through model, the problem disappeared overnight. The unobstructed path allowed the slurry to flow freely. It’s a simple change that makes a huge difference.

Weir-type valves excel in applications like chemical and water treatment[^5] plants. Their excellent sealing prevents hazardous leaks and ensures precise dosing. They handle clean, corrosive, or gassy media beautifully.

Straight-through valves are the workhorses for tough jobs. Think mining, wastewater sludge[^6], power plant ash handling, and flue gas desulfurization. Their straight-through design not only prevents clogging from solids but also minimizes wear and tear from abrasive particles, extending the valve's life in harsh conditions.

Here’s a quick application guide:

| Application Area | Recommended Valve Type | Reason |

|---|---|---|

| Chemical Dosing | Weir-Type | Excellent sealing prevents waste and ensures safety. |

| Abrasive Slurries (Mining) | Straight-Through | Unobstructed path prevents clogging and reduces wear. |

| Wastewater Sludge | Straight-Through | Handles high solids and prevents blockage. |

| Clean Water Treatment | Weir-Type | Superior sealing protects against contamination. |

| Flue Gas Desulfurization (FGD) | Straight-Through | Manages abrasive limestone and gypsum slurries well. |

Conclusion

Choosing correctly is simple: weir-type for superior sealing and control, straight-through for maximum flow and handling slurries. This ensures efficiency, reliability, and a longer service life for your valves.

[^1]: Understanding diaphragm valves is crucial for selecting the right type for your application. [^2]: Explore the unique features and benefits of weir-type valves for various industries. [^3]: Learn about straight-through valves and their advantages in high-flow applications. [^4]: Understand the unique challenges in mining slurry applications and how to address them. [^5]: Discover best practices for selecting valves that ensure clean water treatment. [^6]: Find out which valves are most effective for managing wastewater sludge.