Choosing the wrong diaphragm can lead to leaks and costly downtime. You need a valve that performs reliably. Understanding your material options is the key to long-term success.

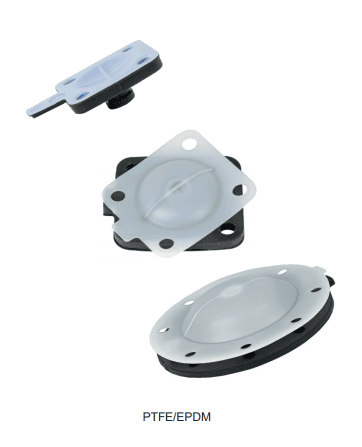

The right choice depends on your application. EPDM[^1] is a flexible, cost-effective option for water and mild chemicals. PTFE[^2] offers superior resistance to aggressive chemicals and extreme temperatures, making it ideal for harsh environments. Both ensure your valve operates efficiently and lasts longer.

I’ve seen many clients struggle with this decision. It’s a critical choice that directly impacts the safety and efficiency of their entire system. Making the wrong call can mean frequent replacements and unexpected failures. That’s why we need to look closer at what makes each material unique. Let's break down the details so you can choose with confidence and avoid future headaches.

What Makes EPDM[^1] a Reliable Choice for Diaphragm Valves?

You need a durable and affordable diaphragm for general applications. But you worry about it wearing out too quickly. EPDM[^1] provides an excellent balance of performance, longevity, and cost-effectiveness.

EPDM[^1] is a synthetic rubber known for its great flexibility[^3], resilience, and resistance to water, steam, and many weak chemicals. This makes it a dependable workhorse for water treatment[^4], HVAC, and food processing[^5], ensuring a tight seal and long service life in non-corrosive systems.

When we talk about EPDM[^1], we are talking about a true all-rounder. Its full name is Ethylene Propylene Diene Monomer, but everyone just calls it EPDM[^1]. Its molecular structure gives it fantastic elasticity. This means it can seal tightly time and time again without losing its shape. I remember a client in the municipal water treatment[^4] sector who was replacing diaphragms every few months. They were using a lower-grade rubber that couldn't handle the constant exposure to water treatment[^4] chemicals like chlorine. We switched them to our high-quality EPDM[^1] diaphragms, and they immediately saw a difference. Their valves now run for years without issues. EPDM[^1] also stands up well to weathering and UV light, making it suitable for outdoor installations.

Here's a simple breakdown:

EPDM[^1] Key Characteristics

| Feature | Benefit |

|---|---|

| Excellent Flexibility | Creates a tight, reliable seal every time. |

| Water & Steam Resistance | Perfect for water treatment[^4] and HVAC systems. |

| Good Chemical Resistance | Handles weak acids, alkalis, and salts well. |

| Cost-Effective | Provides great performance at a lower price point. |

This material is a go-to choice for our cast iron and ductile iron valve bodies, especially in applications where extreme chemical resistance[^6] isn't the primary concern.

When Should You Choose PTFE[^2] for Your Diaphragm Valve?

Your process involves harsh, corrosive chemicals[^7]. A standard rubber diaphragm would dissolve in minutes, causing a dangerous failure. PTFE[^2] offers the ultimate chemical inertness needed to handle these aggressive fluids safely.

Choose PTFE[^2] for applications with aggressive chemicals, solvents, or extreme temperatures. Its chemical inertness and wide temperature range[^8] make it the premium choice for chemical processing and pharmaceutical industries. It provides unmatched reliability where other materials would quickly degrade and fail.

PTFE[^2], often known by the brand name Teflon, is a high-performance fluoropolymer. It's famous for being one of the most chemically resistant materials available. It’s almost completely inert, meaning it won't react with the acids, solvents, or bases flowing through your valve. This is critical in chemical plants where a leak could be catastrophic. We once had a customer developing a new chemical production line. They needed a valve that could handle a highly corrosive proprietary acid at elevated temperatures. EPDM[^1] was not an option. We engineered a custom solution using our ductile iron valve body with a thick, mechanically applied PTFE[^2] lining and a two-piece PTFE[^2] diaphragm. This setup completely isolated the valve body and working parts from the media, ensuring total safety and process purity. The non-stick surface of PTFE[^2] also helps prevent material buildup, which is a big advantage for slurries or sticky fluids.

Let's compare it directly to EPDM[^1]:

PTFE[^2] vs. EPDM[^1]

| Property | PTFE[^2] (Polytetrafluoroethylene) | EPDM[^1] (Ethylene Propylene Diene Monomer) |

|---|---|---|

| Chemical Resistance | Excellent (Inert to most chemicals) | Good (Resists water, steam, weak chemicals) |

| Temperature Range | Wide (-200°C to 260°C) | Moderate (-40°C to 120°C) |

| Flexibility | Stiffer (Often backed by rubber) | Very Flexible |

| Cost | Higher | Lower |

PTFE[^2] is the clear winner for any high-stakes chemical application.

How Does This Choice Apply to Valve Linings Too?

Protecting the diaphragm is only half the battle. Corrosive media will attack and destroy the valve body itself. The same logic for choosing a diaphragm material also applies to the valve lining.

The choice between EPDM[^1] and PTFE[^2] extends directly to valve linings[^9], which protect the entire valve body. EPDM[^1] rubber linings are great for abrasion and water-based media. PTFE[^2] plastic linings offer ultimate corrosion protection for the most demanding chemical applications.

Think of the lining as the valve's armor. It's a layer of protective material that covers all the wetted surfaces of the valve body, preventing the process fluid from ever touching the metal. At our factory, we specialize in manufacturing diaphragm valves[^10] with cast iron (CI) and ductile iron (DI) bodies. These metals are strong and cost-effective, but they need protection from corrosion. This is where linings come in. We use a mechanically applied lining process, which results in a seamless, smooth, and visually superior finish compared to other methods. This ensures there are no weak spots where chemicals could penetrate. For a power plant handling abrasive limestone slurry, a thick EPDM[^1] rubber lining is perfect. It resists wear and provides a long service life. For a chemical plant transferring concentrated sulfuric acid, a PFA or PTFE[^2] plastic lining is the only safe option. It provides a complete, inert barrier.

Here’s how to match linings to common industries:

Lining Material by Industry

| Industry | Common Media | Recommended Lining |

|---|---|---|

| Water Treatment | Chlorinated water, sludge | EPDM[^1] Rubber |

| Power Plants | Ash slurry, process water | EPDM[^1] / Natural Rubber |

| Chemical Processing | Acids, solvents, bases | PTFE[^2] / PFA Plastic |

| Mining | Abrasive slurries | Natural Rubber / EPDM[^1] |

By choosing the right lining, you protect your entire valve investment, not just one part.

Conclusion

Choosing between EPDM[^1] and PTFE[^2] is simple. EPDM[^1] is the versatile workhorse for general use, while PTFE[^2] is the specialist for harsh chemicals. Matching the material to your application ensures reliability.

[^1]: Explore the advantages of EPDM for diaphragm valves, including flexibility and cost-effectiveness. [^2]: Learn why PTFE is the go-to choice for chemical processing due to its unmatched chemical resistance. [^3]: Understand the significance of flexibility in diaphragm materials for effective sealing. [^4]: Find out how EPDM is utilized in water treatment for reliable performance and longevity. [^5]: Discover the role of EPDM in food processing for safe and efficient operations. [^6]: Discover materials that provide superior chemical resistance for safe and efficient valve operation. [^7]: Learn how to select valves that can safely handle corrosive chemicals in various industries. [^8]: Discover the temperature limits of PTFE and EPDM to choose the right material for your application. [^9]: Explore the best materials for valve linings to protect against corrosion and wear. [^10]: Understand the functionality and importance of diaphragm valves in various applications.