Struggling with complex valve installations in corrosive environments? It can be a real challenge. Pneumatic UPVC diaphragm valves with union connections offer an easy, reliable, and cost-effective solution.

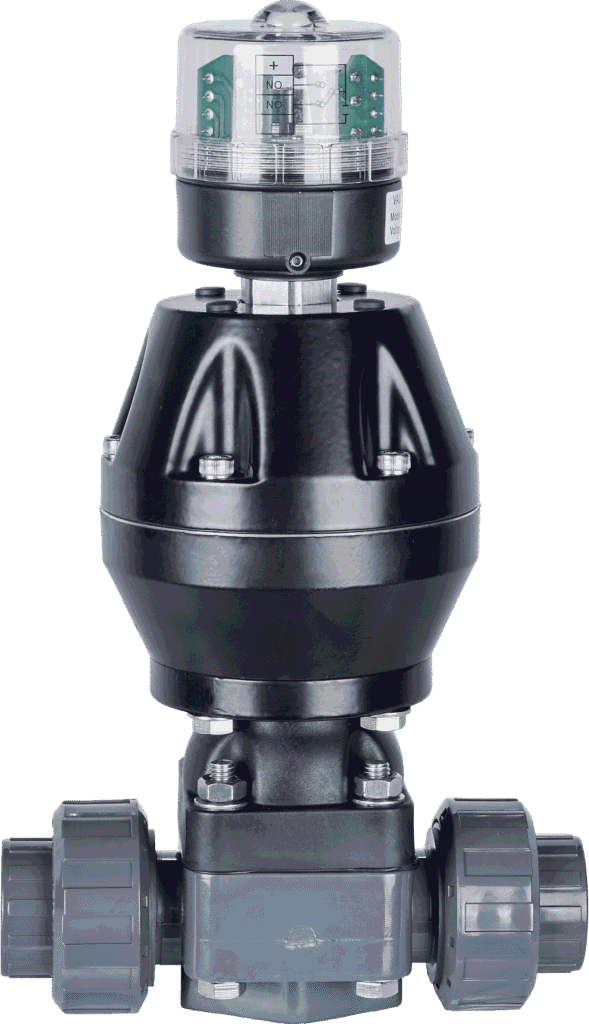

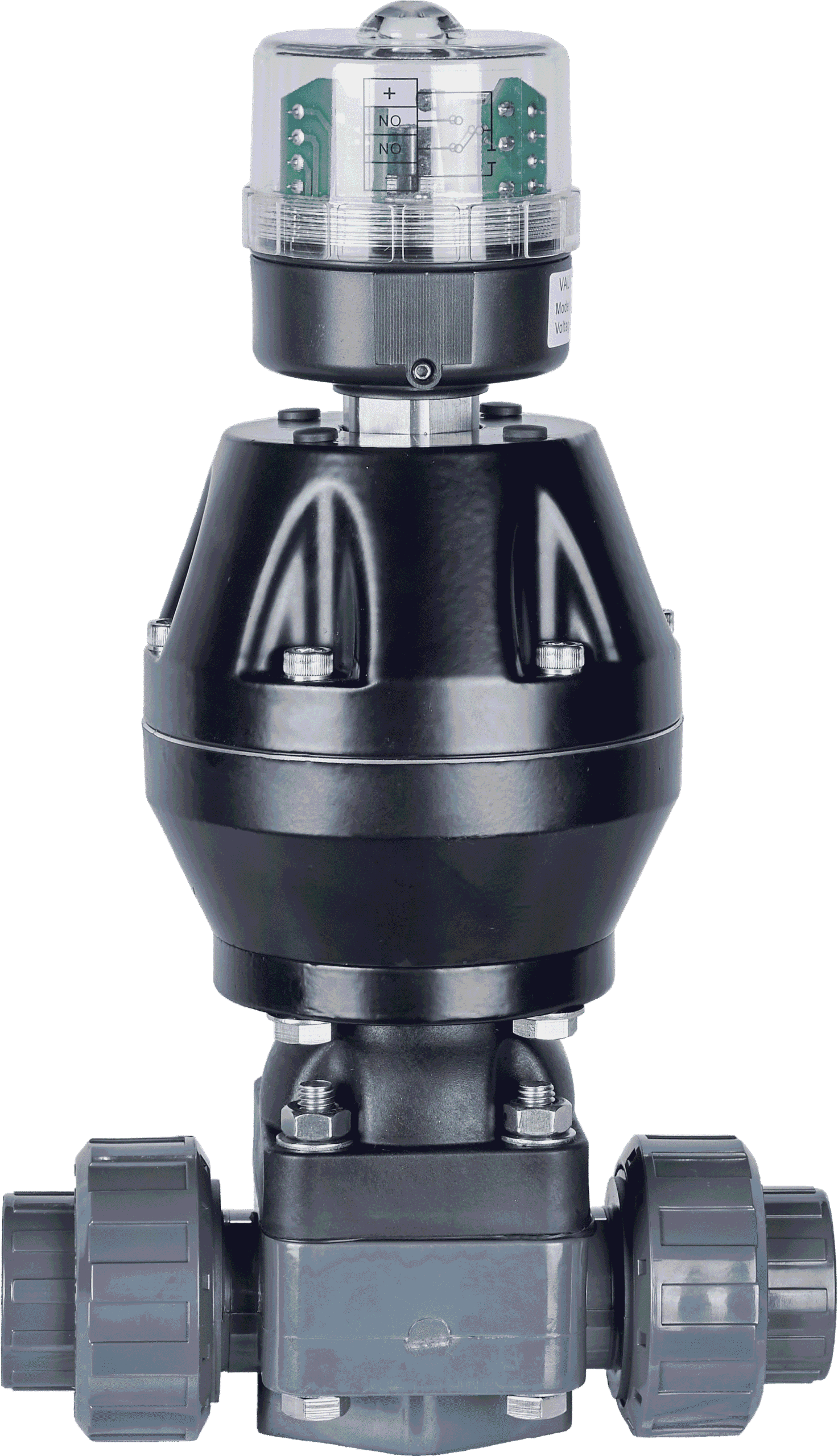

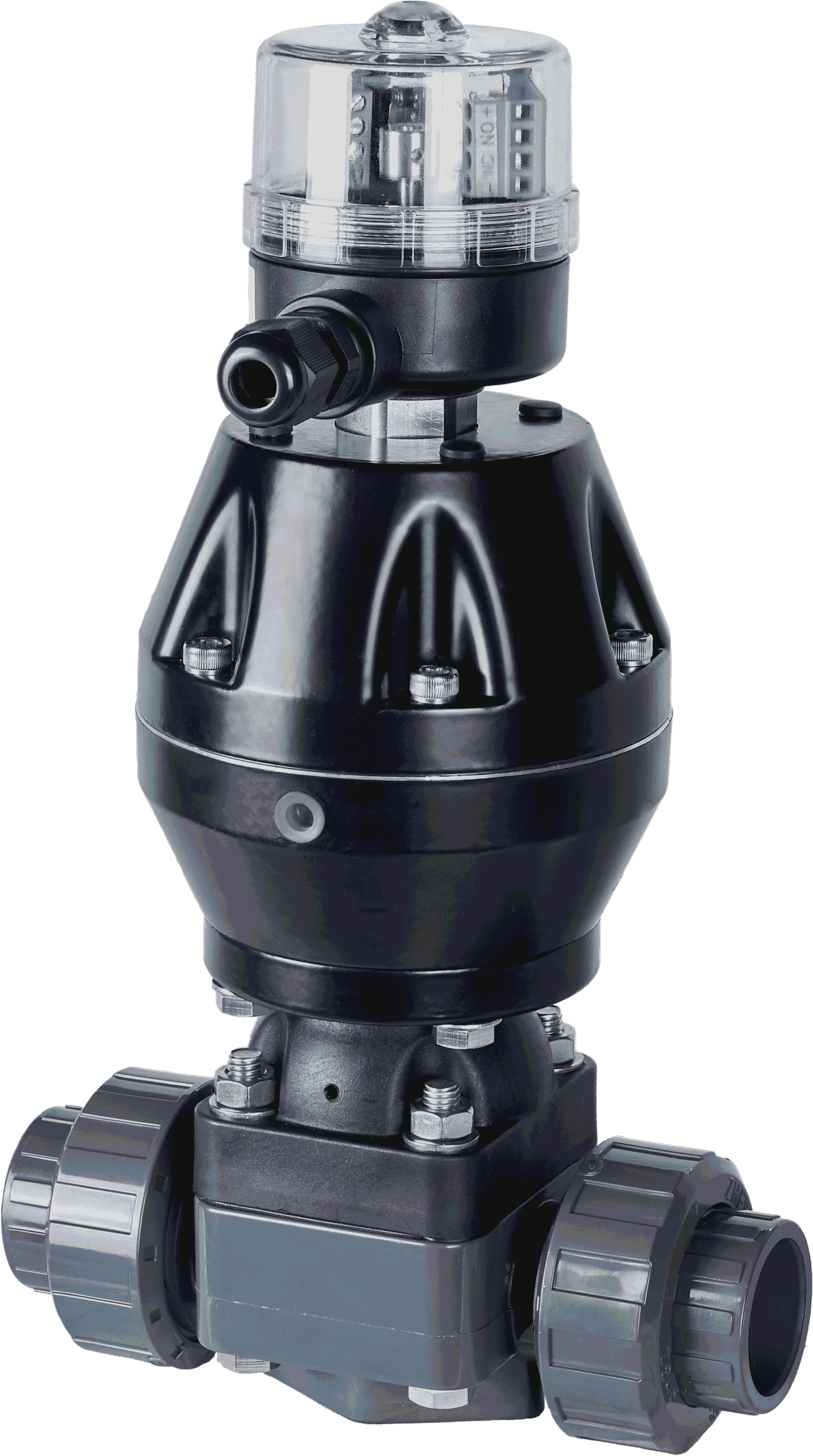

A pneumatic UPVC diaphragm valve is an automated valve featuring a UPVC body, an aluminum pneumatic actuator, and a flexible diaphragm. Its key feature is the use of union connections for extremely simple installation, making it ideal for applications like waste treatment equipment and chemical dosing.

When you're looking for a valve, you need to know if it's the right fit for your specific job. It's not just about turning flow on and off; it's about reliability, ease of maintenance, and long-term performance. Let's take a closer look at these valves to see how their structure, features, and common applications might solve your fluid control problems. Understanding these details will help you make a confident decision for your system.

How is a Pneumatic UPVC Diaphragm Valve put together?

Understanding a valve's internal parts is crucial for maintenance. Without knowing the components, you could struggle with repairs, causing costly downtime. Let's break down the simple structure of these valves.

A pneumatic UPVC diaphragm valve has three main parts: an aluminum pneumatic actuator for automation, a UPVC valve body for corrosion resistance, and a flexible diaphragm that isolates the fluid. The union connections at each end make installation and removal incredibly simple without cutting pipe.

To really get it, you have to look at how the pieces work together. I once had a client who was hesitant about plastic valves, thinking they were less robust than our cast iron models. But when I showed him how this valve was designed for his specific low-pressure chemical line, he saw the logic. The beauty of this valve is its simplicity and how each part is chosen for a specific purpose. The actuator is typically made of a lightweight but strong aluminum alloy. It uses compressed air to move a piston, which in turn opens or closes the valve. The valve body is made from UPVC (Unplasticized Polyvinyl Chloride), which is fantastic against many chemicals. The real magic, however, is in the union connections. Instead of heavy flanges and bolts, you have two simple nuts that you can tighten by hand. This makes swapping out a valve for maintenance an absolute breeze.

Key Components Breakdown

| Component | Material | Function | Key Benefit |

|---|---|---|---|

| Pneumatic Actuator | Aluminum Alloy | Converts compressed air into linear motion to operate the valve. | Provides reliable and fast automated control. |

| Valve Body | UPVC | Contains the fluid and provides the flow path. | Excellent chemical resistance, lightweight, and cost-effective. |

| Diaphragm | EPDM, PTFE, etc. | Isolates the fluid from the actuator and creates the seal. | Prevents leaks and protects working parts from corrosion. |

| Union Connections | UPVC | Connects the valve body to the pipeline. | Allows for quick and easy installation and removal. |

What Makes Pneumatic UPVC Diaphragm Valves a Great Choice?

You need a valve that is not just functional but also reliable. Choosing the wrong valve can lead to leaks, corrosion, and frequent maintenance, hurting your operation's efficiency. These valves offer a unique set of features that solve these problems.

The key features are its excellent corrosion resistance from the UPVC body, the incredibly simple installation via union connections, and reliable automated control from the pneumatic actuator. This combination makes it a cost-effective and low-maintenance option for specific industrial applications that don't involve high pressures or temperatures.

Let's dive deeper into these benefits. I remember a project for a small waste treatment facility. They were using metal ball valves on their dosing lines, and they were failing every few months due to corrosion. On top of that, replacing them was a tough job because of the tight piping. We recommended they switch to these pneumatic UPVC diaphragm valves. The UPVC body completely solved the corrosion issue. More importantly, their maintenance team loved the union connections. What used to be a two-hour job with lots of cursing became a 15-minute swap. The automated control also integrated perfectly with their existing system, improving the accuracy of their chemical dosing. This simple switch saved them thousands in parts and labor within the first year. It's not about being the strongest valve; it's about being the smartest valve for the application.

Feature Comparison: UPVC Diaphragm vs. Metal Ball Valve

| Feature | Pneumatic UPVC Diaphragm Valve | Standard Metal Ball Valve |

|---|---|---|

| Corrosion Resistance | Excellent for many chemicals (acids, alkalis). | Varies by metal; can be poor without expensive alloys. |

| Installation | Very easy with union connections; no special tools. | Can be complex; requires bolting flanges or threading pipe. |

| Maintenance | Simple; diaphragm and body can be replaced quickly. | Often requires full valve replacement; difficult in-line repair. |

| Control | Good for on/off and some throttling; isolates media. | Excellent for on/off; can be poor for throttling. |

| Cost | Generally lower for corrosive, low-pressure service. | Can be very high for corrosion-resistant alloys. |

Where Are Pneumatic UPVC Diaphragm Valves Most Commonly Used?

Choosing the right valve for the right job is critical. Using the wrong type can lead to premature failure or inefficient flow control, costing you money and time. Let's look at the specific applications where these valves truly shine.

Pneumatic UPVC diaphragm valves are ideal for low-pressure, corrosive fluid applications. You'll often find them in water treatment, chemical dosing systems, and especially on waste treatment equipment where their easy installation and chemical resistance are major advantages.

The main reason they are so popular in these areas is the perfect match between the valve's features and the application's demands. Take waste treatment equipment, for example. The fluid streams can be a nasty mix of unknown chemicals, so you need a material that won't corrode easily. UPVC is perfect for this. These systems also rely on automated processes to manage flow rates and chemical additions, so a pneumatic actuator is a must. I have a customer who builds compact waste treatment skids. They use our pneumatic UPVC valves exclusively. They told me that the union connections are a lifesaver during assembly. It allows them to build the piping runs and then just drop the valves in at the end, saving a huge amount of time compared to fitting flanged valves. It’s this combination of chemical resistance, automation, and ease of handling that makes it the go-to choice for these specialized industries.

Top Application Areas

| Application | Challenge | Why a Pneumatic UPVC Diaphragm Valve is the Solution |

|---|---|---|

| Waste Treatment Skids | Corrosive media, need for automation, and compact space for installation. | UPVC body resists corrosion, actuator provides automation, and union connections make installation fast and easy. |

| Chemical Dosing | Precise control needed for aggressive chemicals like sodium hypochlorite or acids. | The diaphragm design provides a leak-free seal, and the UPVC body is immune to many dosing chemicals. |

| Water Purification | Maintaining water purity and handling treatment chemicals without contamination. | The UPVC material is non-leaching, and the diaphragm isolates the media from all valve working parts. |

| Aquaculture | Controlling saltwater or treated water flow without metal corrosion. | The all-plastic and rubber construction is completely resistant to saltwater corrosion. |

Conclusion

In short, pneumatic UPVC diaphragm valves are an excellent, cost-effective choice for corrosive, low-pressure applications where easy installation and automated control are essential. They are a problem-solver for many industries.