Choosing the right automated valve can be confusing. You see terms like "Normally Open" or "Double Acting" and wonder what's best. Let's clear up the confusion right now.

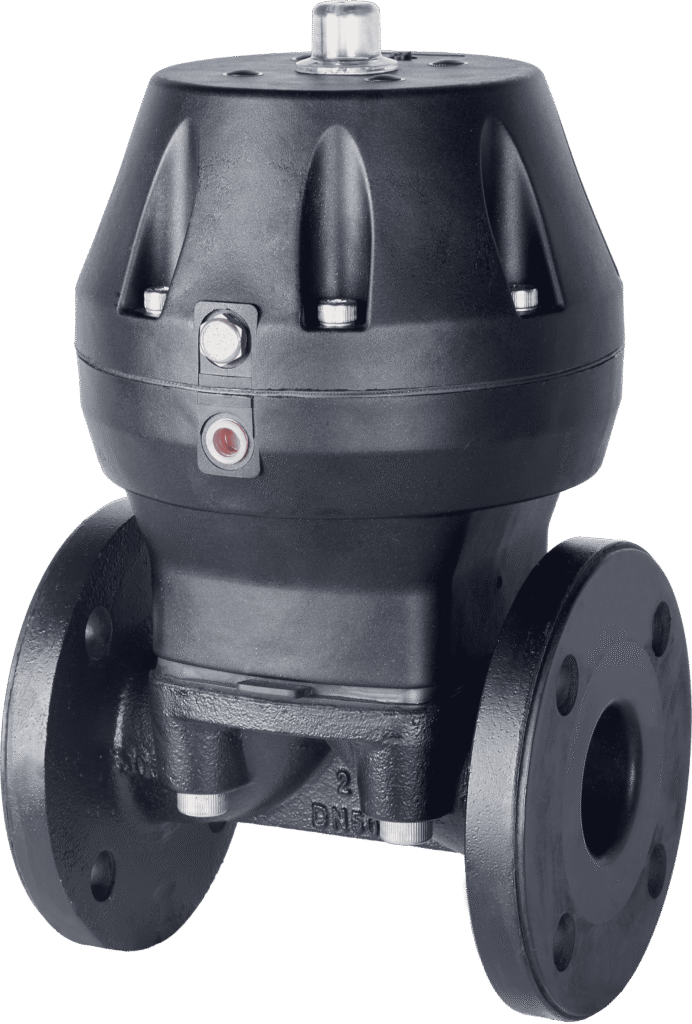

A pneumatic diaphragm valve[^1] operates in one of three ways. Normally Closed (NC)[^2] uses air to open and a spring to close. Normally Open (NO)[^3] uses air to close and a spring to open. Double Acting (DA)[^4] uses air for both opening and closing actions.

What Is a Normally Closed (NC)[^2] Pneumatic Diaphragm Valve?

Worried about what happens if your air supply cuts out? A system failure could cause a dangerous leak. A Normally Closed valve provides an automatic, fail-safe shutoff[^6].

A Normally Closed (NC)[^2] pneumatic diaphragm valve[^1], also called "Fail-to-Close," uses a powerful spring to hold it in the closed position. You need to apply compressed air to overcome the spring and open the valve. When the air is gone, it automatically closes.

How NC Valves Work

The operation is straightforward. The spring provides the force to seal the valve. When you want to let fluid pass, compressed air is fed into the actuator, which pushes against a piston or diaphragm, compresses the spring, and lifts the valve's diaphragm off its seat.

| Air Supply Status | Valve Position | Reason |

|---|---|---|

| Air On | Open | Air pressure overcomes the spring force. |

| Air Off | Closed | Spring force pushes the diaphragm closed. |

This design is the most common choice for general-purpose applications and is especially critical for safety lines where you need to stop the flow during an emergency shutdown.

And What About a Normally Open (NO)[^3] Pneumatic Diaphragm Valve?

Some processes must keep flowing, even if control systems fail. An unexpected shutdown could block a critical line or ruin an entire batch of product. This is where a Normally Open valve helps.

A Normally Open (NO)[^3] pneumatic diaphragm valve[^1], or "Fail-to-Open," is the opposite of an NC valve. A spring holds it in the open position, allowing fluid to pass. You must apply compressed air to force the valve closed and stop the flow.

The Mechanics of NO Valves

The internal mechanics are a mirror image of the NC valve. The spring's natural state is to keep the valve open for maximum flow. To close it, compressed air is introduced to the actuator, which works against the spring's force to push the diaphragm down onto the weir and create a seal.

| Air Supply Status | Valve Position | Reason |

|---|---|---|

| Air On | Closed | Air pressure overcomes the spring force. |

| Air Off | Open | Spring force pulls the diaphragm open. |

Choose this valve for applications like emergency cooling systems[^7], pressure relief lines[^8], or any process where a loss of flow is more dangerous than an uncontrolled flow.

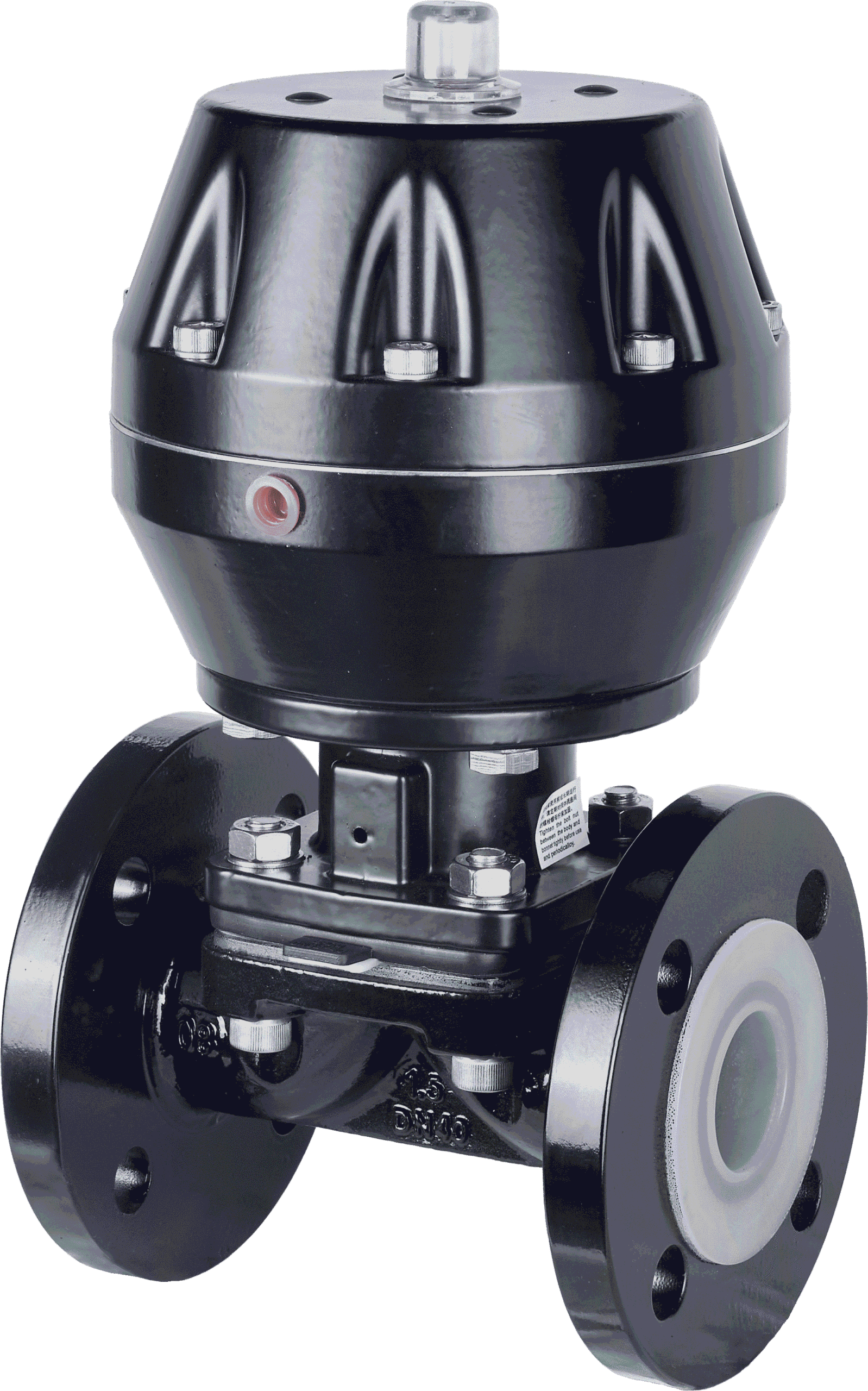

So, What Makes a Double Acting (DA)[^4] Pneumatic Diaphragm Valve Different?

Sometimes you need precise control over both opening and closing. A spring-return valve might not have enough force for thick slurries or high-pressure lines[^9]. A Double Acting valve gives you powerful, controlled actuation.

A Double Acting (DA)[^4] pneumatic diaphragm valve[^1] has no spring. It uses compressed air to both open the valve and close it. If the air supply fails, the valve simply stays in its last position, whether that was open, closed, or somewhere in between.

Understanding the DA Mechanism

The actuator on a DA valve has two air connection ports. You send air to one port to open the valve and to the other port to close it. This gives you complete and powerful control in both directions. It's ideal for throttling applications where you need to hold the valve in a partially open position to control the flow rate.

| Action Required | Port 1 (Open) | Port 2 (Close) | Resulting Valve Position |

|---|---|---|---|

| Open Valve | Pressurize | Vent | Open |

| Close Valve | Vent | Pressurize | Closed |

| Air Failure | No Air | No Air | Stays in Last Position |

This valve is the best choice for handling viscous media[^10], high pressures, or when you need modulating control and a "stay-put" failure position.

Conclusion

Choosing between Normally Open, Closed, or Double Acting depends on your process needs and safety requirements. Understanding this makes selecting the right valve simple and effective for your business.

[^1]: Gain insights into the functionality and applications of pneumatic diaphragm valves in fluid control. [^2]: Explore this link to understand how NC valves provide fail-safe shutoff in critical applications. [^3]: Learn about NO valves and their importance in ensuring continuous flow during control system failures. [^4]: Discover how DA valves offer precise control and powerful actuation for demanding applications. [^5]: Explore the role of compressed air in operating pneumatic valves and its impact on system safety. [^6]: Understand the concept of fail-safe shutoff and its significance in preventing leaks and spills. [^7]: Discover the critical role of emergency cooling systems in preventing equipment overheating. [^8]: Understand the function of pressure relief lines in maintaining system integrity and safety. [^9]: Understand the requirements and considerations for managing high-pressure lines effectively. [^10]: Learn about the challenges of handling viscous media and the solutions provided by specialized valves.