Handling aggressive industrial fluids wears out standard valves fast. This leads to leaks and costly downtime. Diaphragm valves[^1] isolate harsh media, ensuring process integrity and extending service life.

Diaphragm valves[^1] excel by using a flexible diaphragm to isolate corrosive chemicals, abrasive slurries, and viscous dyes from the valve's working parts. This design prevents leaks, contamination, and wear, making them ideal for chemical processing[^2], textile, and pulp and paper applications.

It's one thing to say these valves work well, but it's another to see exactly how they solve real-world problems. As a manufacturer, I've seen firsthand how the right valve can transform an entire operation. Let's break down how diaphragm valves solve specific challenges in each of these demanding sectors.

Why Are Diaphragm Valves a Top Choice for Chemical Processing?

Aggressive acids and solvents corrode valve components, causing dangerous leaks. A single failure means safety hazards and ruined product batches. Diaphragm valves[^1] with specialized linings contain these chemicals safely.

Diaphragm valves[^1] are a top choice because their design completely isolates the process fluid from the valve's metal parts. With linings like PFA or PTFE, they offer superior corrosion resistance against acids, alkalis, and solvents, ensuring leak-free performance and process purity in reactors and dosing systems.

I've worked with many chemical plant managers who were constantly battling valve failures. The issue always comes back to direct contact between aggressive media and the valve's internal metal parts. This is where the diaphragm valve truly shines.

The Challenge of Corrosive Fluids

In chemical processing[^2], you're dealing with everything from sulfuric acid to caustic soda. Traditional valves, like ball or gate valves, have complex internal geometries with many moving parts exposed to the fluid. This creates opportunities for corrosion to attack seals, stems, and bodies, leading to inevitable leaks. A leak isn't just a maintenance headache; it's a serious safety risk and can contaminate an entire production run. We designed our valves to solve this exact problem. Our valve bodies, cast using a resin-coated sand process, have fewer imperfections, providing a perfect base for our superior linings.

The Diaphragm Valve Solution

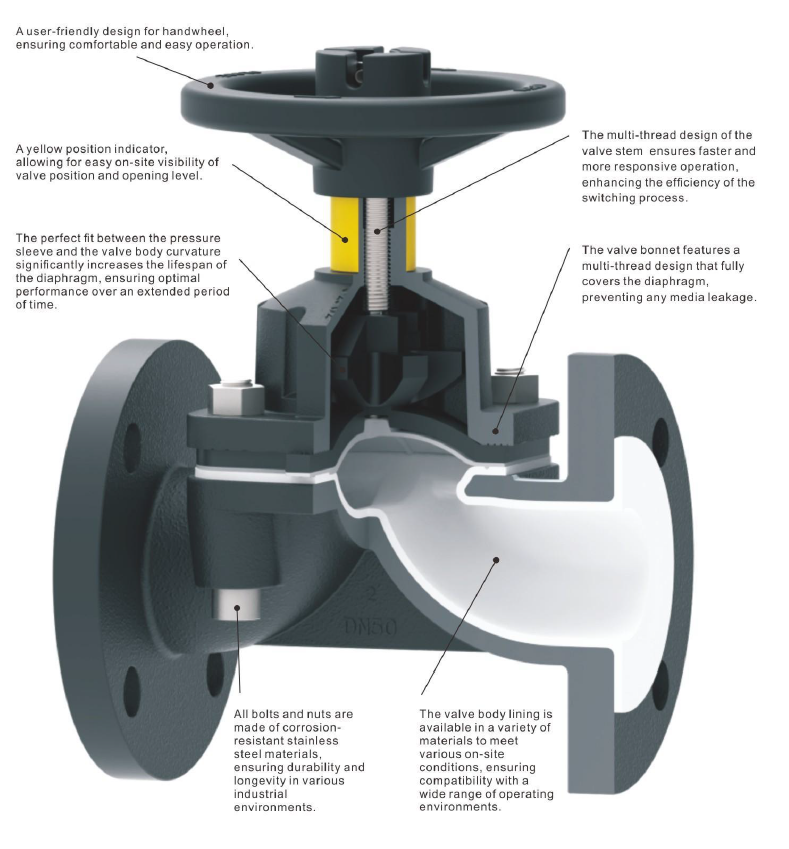

The core of the solution is total media isolation. The diaphragm acts as a barrier, keeping the corrosive chemical contained within the lined body of the valve. The valve's bonnet and actuator mechanism never touch the fluid. This simple but effective design eliminates the primary cause of valve failure in chemical applications. Our mechanically applied PFA and PTFE linings are seamless and smooth, preventing chemical permeation and delamination, which are common issues with lower-quality lined valves. This ensures long-term, leak-free service.

| Chemical | Recommended Lining | Performance Note |

|---|---|---|

| Sulfuric Acid (98%) | PTFE / PFA | Excellent resistance, prevents dangerous leaks. |

| Sodium Hydroxide | EPDM / PTFE | EPDM is cost-effective; PTFE for high purity. |

| Solvents (e.g., Toluene) | PTFE / PFA | Resists swelling and degradation. |

How Do Diaphragm Valves Survive in the Abrasive Pulp and Paper Industry?

Abrasive wood pulp and lime slurries quickly erode and clog traditional valves. This causes frequent shutdowns and inconsistent flow. The straight-through design of a weir-type diaphragm valve[^3] handles these slurries easily.

Diaphragm valves[^1] survive by offering a smooth, pocketless flow path that minimizes friction and prevents abrasive slurries[^4] from getting trapped. The resilient rubber lining[^5] withstands wear, and the tight seal prevents leaks, ensuring reliable control of pulp, lime slurry, and other challenging media.

Paper mills are tough environments for any piece of equipment. I remember visiting a client whose limestone slurry lines were a constant source of trouble. The gate valves they used were getting chewed up by the abrasive particles, forcing them to replace the valves every few months. The downtime was killing their productivity. We introduced them to our rubber-lined diaphragm valves, and it completely changed their maintenance schedule.

The Problem with Abrasive Slurries

The main issue with slurries is a combination of abrasion and clogging. Fluids with high solids content, like wood pulp or calcium carbonate, act like liquid sandpaper, wearing away at metal surfaces. In valves with complex internal paths, like globe or ball valves, these solids can settle in cavities and crevices. This build-up eventually obstructs the valve, causing it to fail or clog the entire line. This leads to unplanned stops in a 24/7 production process, which is incredibly expensive.

The Advantage of a Clear Flow Path

A weir-type diaphragm valve[^3] has a simple, streamlined flow path. When open, it's almost like a straight piece of pipe. This design minimizes turbulence and gives abrasive particles nowhere to hide or settle. The soft, resilient rubber lining[^5] absorbs the impact of the particles instead of being worn away by them. When the valve closes, the diaphragm presses down firmly on the weir, providing a bubble-tight seal even with solids present in the line. This combination of a clear path and a durable lining is the key to longevity in these applications.

| Valve Type | Clogging Risk | Abrasion Resistance | Maintenance Needs |

|---|---|---|---|

| Diaphragm Valve | Low | Excellent (with rubber) | Low |

| Ball Valve | High | Poor | High |

| Gate Valve | Medium | Poor to Fair | High |

What Makes Diaphragm Valves Essential for Modern Textile Manufacturing?

Inconsistent dye flow and chemical dosing[^6] ruin expensive fabric batches. Contamination between colors leads to waste and off-spec products. Diaphragm valves[^1] give you the precise control and tight shut-off needed for perfect dyeing.

Diaphragm valves[^1] are essential because they provide precise flow control[^7] and bubble-tight shutoff, crucial for managing dye solutions and chemicals. Their crevice-free design prevents cross-contamination between batches and ensures consistent, repeatable results, protecting fabric quality and minimizing waste.

The textile industry is all about color consistency and quality. A client once told me they were struggling with "color bleeding" in their dyeing machines. They were using ball valves, and small amounts of dye were getting trapped in the valve's body cavity. When they switched to the next color, this trapped dye would leach out and contaminate the new batch, ruining meters of fabric. We replaced their ball valves with our diaphragm valves. Because our valves have no such cavities, the problem disappeared overnight.

The Need for Precision and Purity

Textile processing involves a sequence of carefully controlled chemical applications, from bleaching and dyeing to finishing. Each step requires precise dosing and zero contamination from the previous step. A valve that doesn't shut off completely or has internal "dead spots" where fluid can get trapped is a major liability. It can lead to inconsistent color, spots on the fabric, and huge amounts of wasted material, water, and chemicals. The goal is perfect repeatability, batch after batch, and the valve is a critical component in achieving that.

How Diaphragm Valves Ensure Quality

The diaphragm valve's design is inherently clean. The smooth, contoured flow path has no crevices or pockets for dyes or chemicals to accumulate. When the valve closes, the diaphragm seals tightly against the weir, providing a leak-proof shut-off. This ensures that when a process is finished, it's truly finished, and there's no risk of cross-contamination. This design also allows for very fine throttling control, which is important for accurately dosing chemicals or regulating the flow of dye. Whether you need a simple manual valve for a small tank or a fully automated pneumatic valve for a large dyeing machine, the principle remains the same: clean, precise, and reliable control.

| Textile Chemical | Recommended Lining | Key Benefit |

|---|---|---|

| Dye Solutions | EPDM | Good chemical compatibility, cost-effective. |

| Bleaching Agents (Hypochlorite) | EPDM / Butyl | Resists oxidation and degradation. |

| Acids/Alkalis (pH adjust) | EPDM / PTFE | Broad resistance for various dosing needs. |

Conclusion

Diaphragm valves[^1] are a robust solution for the chemical, paper, and textile industries. They ensure safety, efficiency, and quality by isolating and controlling even the most challenging industrial fluids.

[^1]: Learn how diaphragm valves provide superior isolation and durability in harsh environments. [^2]: Explore the advantages of using diaphragm valves in handling corrosive chemicals safely. [^3]: Discover the design and benefits of weir-type diaphragm valves in handling abrasive materials. [^4]: Find out how abrasive slurries can cause wear and clogging in valves, affecting performance. [^5]: Learn how rubber lining provides abrasion resistance and extends valve life in harsh conditions. [^6]: Learn how diaphragm valves provide accurate chemical dosing, crucial for process efficiency. [^7]: Understand the mechanisms that allow diaphragm valves to offer accurate and reliable flow control.