Struggling with leaks, contamination, or high-maintenance valves? These problems cause costly downtime and safety risks. Discover a valve designed to solve these issues from the ground up.

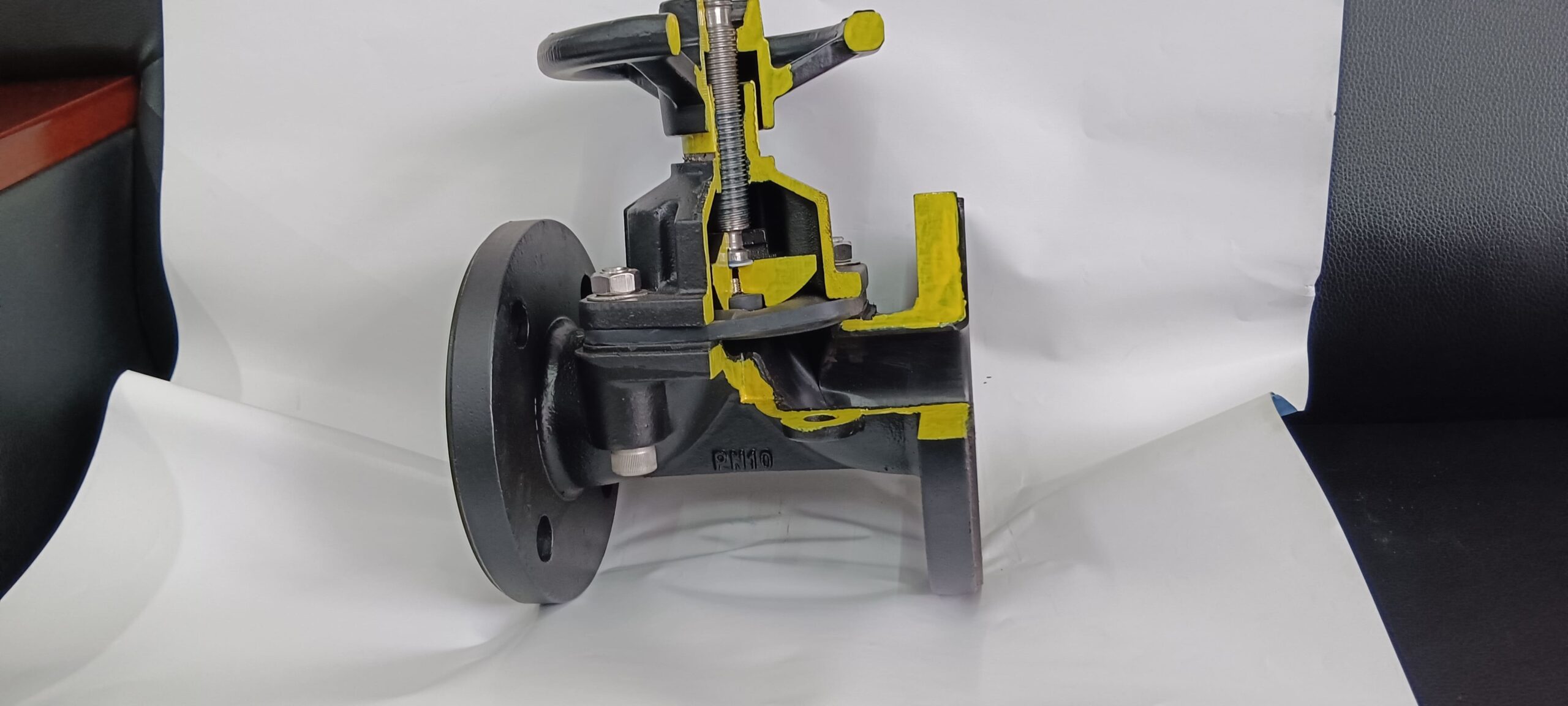

A diaphragm valve[^1] uses a flexible diaphragm[^2] to control flow. When closing, an actuator pushes the diaphragm against a seat, sealing the path and isolating the fluid from all moving parts. When opening, the diaphragm lifts, creating a smooth, unobstructed channel.

The basic principle seems simple, but the real genius is in the details of its design. This unique structure is what gives the diaphragm valve[^1] its powerful advantages in so many industries. Let's break down exactly what makes this valve a game-changer for businesses like yours.

What Makes the Diaphragm Valve's Sealing Mechanism So Unique?

Worried about your process fluid getting contaminated by lubricants or the atmosphere? Even a small leak can ruin a product batch. The diaphragm valve[^1]'s unique design offers complete isolation.

Its uniqueness comes from the diaphragm itself, which acts as both the flow controller[^3] and the seal. It creates a physical barrier, completely isolating the fluid from the valve's stem, actuator, and the outside environment. This means there are no packing glands to leak or fail.

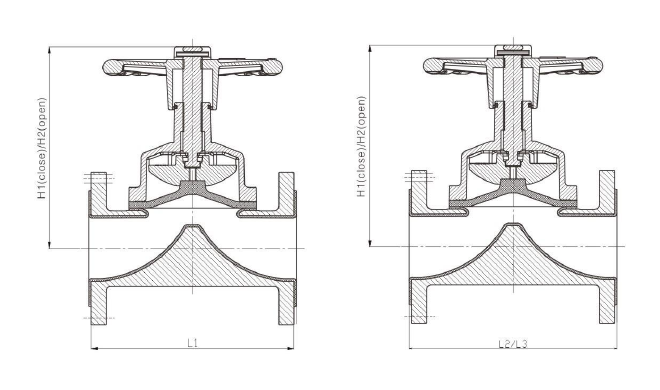

Let's explore this further. The key is the total isolation of the operating mechanism. In many traditional valves, like gate or globe valves, the stem moves through a packing seal to operate the valve. This packing can wear out over time, creating a potential leak path for the fluid to escape or for contaminants to enter. The diaphragm valve[^1] eliminates this weak point entirely. The diaphragm is clamped between the valve body and the bonnet, creating a static, leak-proof seal to the outside. There are two primary designs you'll encounter:

- Weir-Type[^4]: The diaphragm pushes down onto a raised "weir" in the valve body. This design allows for shorter strokes and is excellent for throttling and precise control.

- Straight-Through Type[^5]: The diaphragm seals against the bottom of a straight, tube-like body. This offers an unobstructed flow path, making it ideal for slurries or viscous fluids.

| Feature | Weir-Type[^4] Diaphragm Valve | Straight-Through Diaphragm Valve |

|---|---|---|

| Flow Path | Contoured over a weir | Unobstructed, straight |

| Best For | Throttling, clean fluids | Slurries, viscous fluids |

| Sealing | Shorter stroke, tighter shut-off | Longer stroke, full-bore flow |

| Drainage | Good, but can trap fluid | Excellent, fully drainable |

This fundamental design difference is why we see them used everywhere, from chemical plants to water treatment facilities. The integrity of the seal is unmatched.

How Does the Diaphragm's Material Impact Valve Performance?

Afraid of valve failure due to aggressive chemicals or abrasive slurries? A poor material choice leads to costly shutdowns and replacements. The diaphragm material is your first line of defense.

The diaphragm material directly determines the valve's chemical compatibility[^6], temperature limits, and lifespan. Elastomers like EPDM offer flexibility for general use, while plastics like PTFE[^7] provide superior resistance to highly corrosive chemicals. The right choice ensures reliable, long-term performance.

The diaphragm isn't just a piece of rubber; it's a highly engineered component. The choice of material is critical and depends entirely on the application. We can group these materials into two main families: rubbers (elastomers) and plastics (plastomers).

- Rubber Linings (Elastomers): Materials like EPDM, NBR, and natural rubber are known for their flexibility and durability. EPDM is a workhorse in water treatment plants because it resists many common chemicals. NBR is great for oils and fuels. These materials provide a bubble-tight seal and can handle some abrasion.

- Plastic Linings (Plastomers): When you're dealing with extremely corrosive substances like strong acids or solvents, you need a plastic lining. PTFE[^7] is the gold standard here. It is nearly chemically inert. However, PTFE[^7] is less flexible than rubber, so the valve design must account for this. At our factory, we pair these diaphragms with robust cast iron (CI) or ductile iron (DI) bodies. The body provides the strength, while the diaphragm and its matching body lining provide the corrosion resistance[^8].

| Material | Common Use Cases | Key Advantage |

|---|---|---|

| EPDM | Water, Wastewater, Steam | Excellent weather and water resistance |

| NBR | Oils, Fuels, Solvents | Superior oil resistance |

| PTFE[^7] | Aggressive Acids, Bases | Nearly universal chemical resistance |

| PFA | High-Purity Chemicals | High-purity version of PTFE[^7] |

Choosing the right combination is a service we provide to our OEM/ODM partners to ensure the final product is perfect for their customers' needs.

Why Are Diaphragm Valves Essential in High-Purity Industries?

Does your process demand absolute purity, where any contamination is a disaster? A single particle can ruin a batch of medicine or a silicon wafer. This is where diaphragm valve[^1]s shine.

They are essential because their design offers a sterile, crevice-free flow path with zero dead space. The fluid only touches the inert diaphragm and body liner, preventing contamination. This ensures the purity and integrity of the final product, which is non-negotiable in these fields.

The concept of a "sterile and non-contaminating flow path" is the core reason for their dominance in high-purity applications. Unlike other valves, a well-designed diaphragm valve[^1] has no cavities or "dead legs" where fluid can stagnate and breed bacteria. The smooth, contoured interior allows for easy cleaning and complete drainage. This is critical for Clean-in-Place (CIP)[^9] procedures. I remember working with a pharmaceutical client on a facility upgrade. They were using valves that took 3-5 hours to clean between batches. By switching to our elastomer-lined diaphragm valve[^1]s, they cut that cleaning time down to just 1.2 hours. That's a huge boost in production efficiency. In another case, a semiconductor manufacturer was struggling with wafer yield loss. We supplied them with high-purity diaphragm valve[^1]s. The result? A 65% reduction in yield loss. This was because our valves prevented microscopic particles from the valve mechanism from entering the ultrapure water stream. Our mechanically applied, seamless linings also contribute to this by providing a smoother, less-porous surface than traditional methods.

What Are the Key Advantages of Using Diaphragm Valves in Your System?

As a distributor or brand owner, you need a valve that is reliable and easy to sell. Offering a product with frequent issues hurts your reputation. Diaphragm valves offer a unique set of advantages.

The main advantages are absolute sealing with zero leakage, a non-contaminating flow path, excellent corrosion resistance, and low maintenance. This combination leads to a long service life, increased operational safety, and a lower total cost of ownership for the end-user.

Let's put all the pieces together. For our B2B partners, understanding these advantages is key to positioning the product correctly.

1. Absolute Sealing and Zero Leakage

This is the biggest selling point. Because the diaphragm isolates the fluid from the actuator and the environment, the risk of external leaks is eliminated. This is vital for hazardous chemicals[^10] and for preventing product loss.

2. Uncontaminated Flow Path

The fluid only ever touches the valve body lining[^11] and the diaphragm. There are no lubricants from the actuator that can mix with the fluid. The smooth, often weir-style path also prevents clogging, which is why they perform so well in power plant ash slurry lines.

3. Excellent Corrosion and Abrasion Resistance

Our approach is to use a strong, affordable cast iron or ductile iron body and protect it with a high-performance lining. This gives you the corrosion resistance[^8] of an expensive alloy valve but at a fraction of the cost. It's a smart, economical design.

4. Low Maintenance and Long Service Life

The only part that typically wears out is the diaphragm itself. And replacing it is simple. You can do it without even taking the valve body out of the pipeline. This drastically reduces downtime and maintenance costs over the valve's life. It's a fit-and-forget solution for many applications.

Conclusion

In summary, the diaphragm valve[^1]'s unique design provides a leak-proof, contamination-free, and low-maintenance solution for controlling challenging industrial fluids, making it a reliable and cost-effective choice.

[^1]: Explore the advantages of diaphragm valves, including their unique sealing mechanism and low maintenance needs. [^2]: Learn how flexible diaphragms control flow and enhance valve performance in various industries. [^3]: Discover the importance of flow controllers in ensuring efficient fluid management. [^4]: Explore the specific uses and advantages of Weir-Type diaphragm valves in various processes. [^5]: Learn about the advantages of Straight-Through Type valves for unobstructed flow. [^6]: Discover how the right diaphragm material ensures long-lasting performance in harsh environments. [^7]: Learn about PTFE's chemical resistance and its critical role in high-performance diaphragm valves. [^8]: Learn about the materials and designs that give diaphragm valves their superior corrosion resistance. [^9]: Discover how diaphragm valves simplify CIP procedures, enhancing efficiency in cleaning. [^10]: Learn about the safety features of diaphragm valves that protect against leaks and contamination. [^11]: Discover how valve body linings enhance performance and protect against corrosion.