Struggling with constant valve replacements in your wastewater plant? The high costs and downtime are eating into your budget. This endless maintenance cycle drains resources and puts your operations at risk.

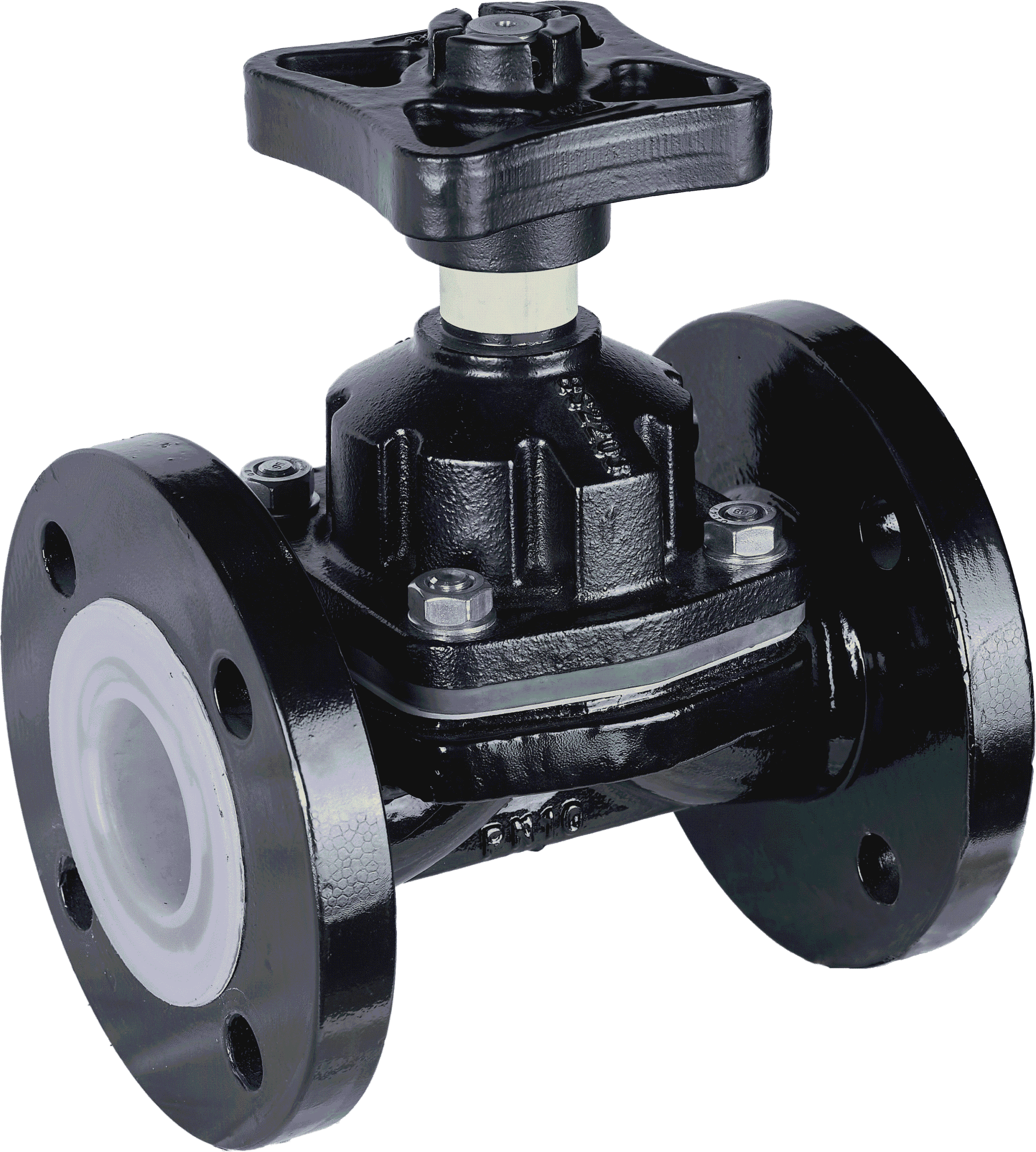

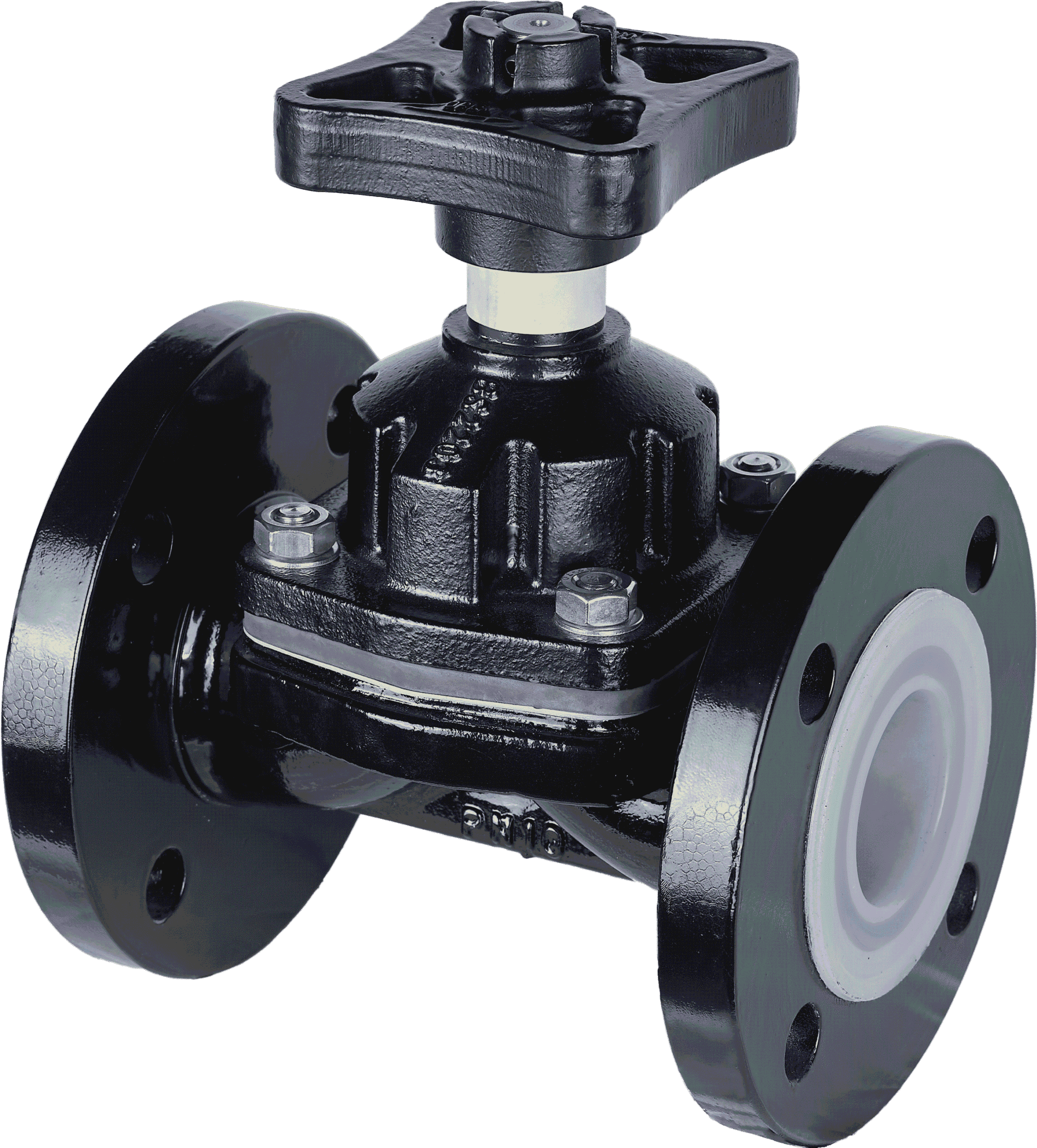

Fluorine-lined diaphragm valves[^1] provide superior corrosion resistance[^2], drastically cutting maintenance needs. In some municipal projects, they've reduced replacement frequency from three times a year to just once, slashing maintenance costs[^3] by an incredible 60% and ensuring long-term operational stability for your plant.

I've seen firsthand how the right valve can transform an entire operation. A client once told me their maintenance team was spending more time fixing leaks than on preventative work. It was a constant battle. But what makes these valves so effective in such a demanding environment? Let's break it down. It’s not just about the material; it’s about the design and how it solves specific challenges in wastewater treatment.

Why are fluorine-lined valves the "wastewater busters"?

Harsh chemicals in wastewater, like coagulants and disinfectants, quickly degrade standard valves. This leads to frequent leaks and failures. You're constantly worried about chemical spills and the high cost of replacing components.

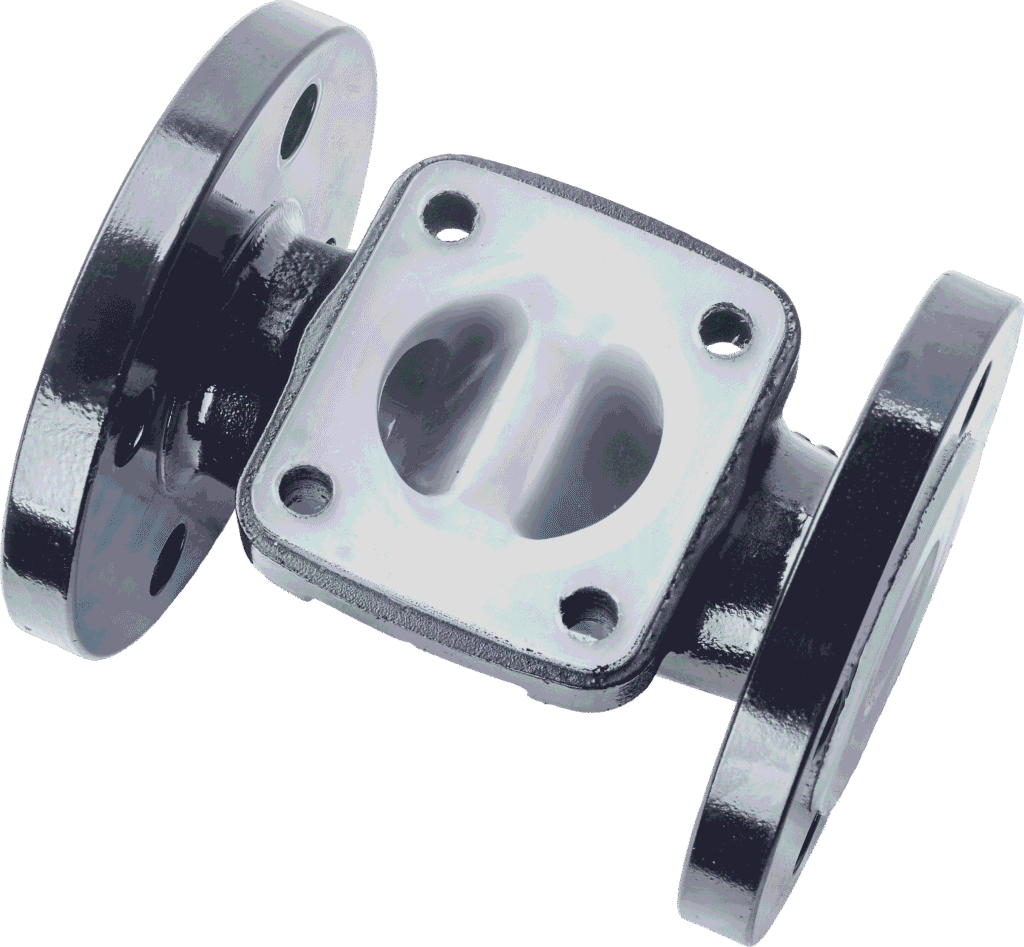

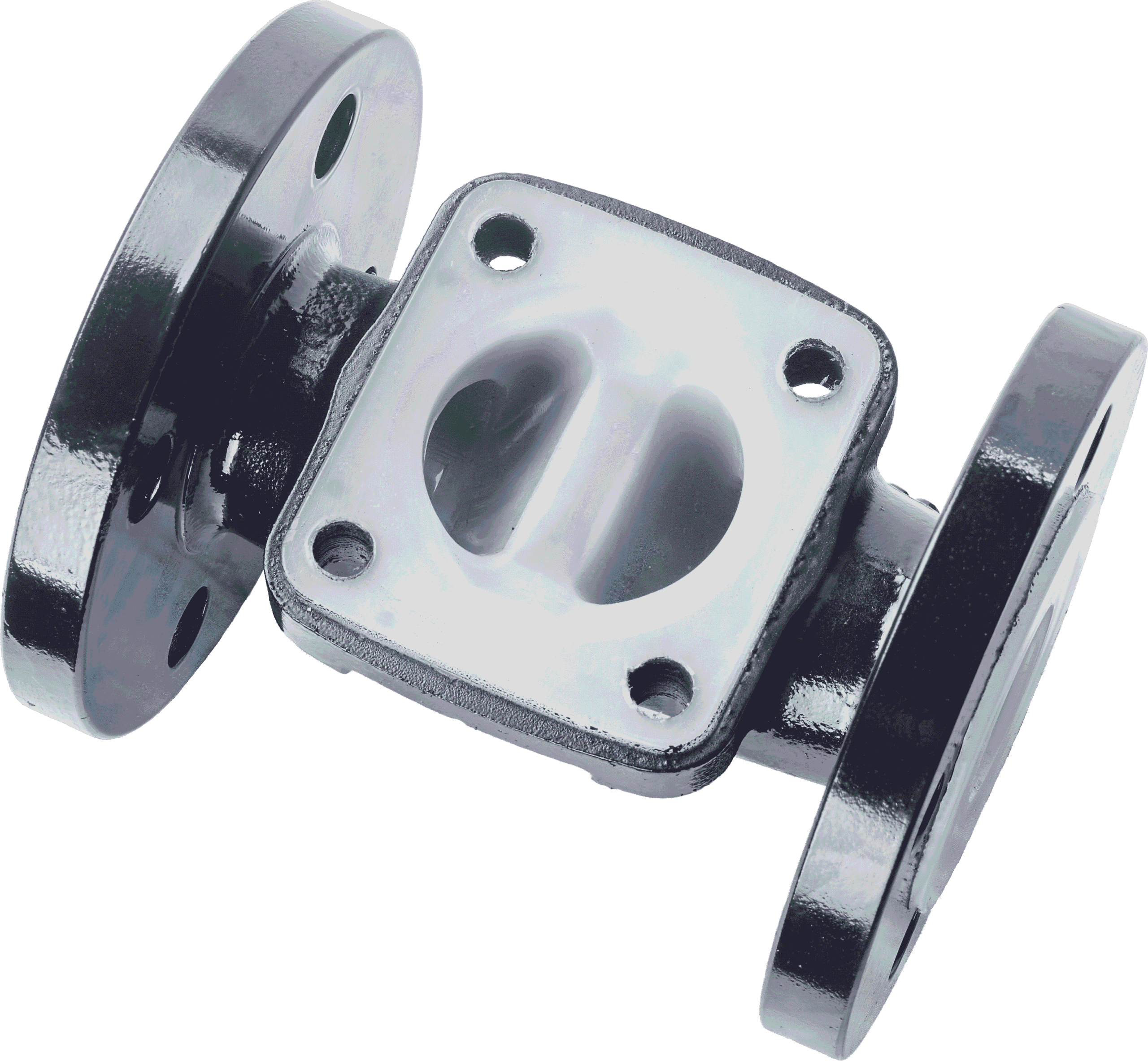

Fluorine linings like PFA and PTFE[^4] offer near-universal chemical resistance[^5]. They form a seamless, non-porous barrier that protects the valve body from aggressive chemicals used in dosing systems, such as sodium hypochlorite[^6] and acids, preventing leaks and extending the valve's lifespan significantly.

Let's get into the specifics of why these linings are so powerful. Wastewater treatment involves a complex mix of chemicals. You have coagulants, flocculants, disinfectants, and pH adjusters. Each of these can be highly corrosive. Standard valves, even those made of special alloys, can struggle. But fluorine-based plastics are different. Think of the lining as a complete shield. It totally isolates the cast iron valve body from the fluid. This means the structural part of the valve never touches the corrosive media. Our mechanically applied linings are seamless and smoother. This is important because a smoother surface reduces friction and potential buildup. Other methods can leave seams or imperfections. These become weak points for chemical attack over time. The integrity of that lining is everything.

The Power of Fluoropolymer Linings

This combination of superior material and superior application is how we achieve a lifespan of over 5 years. It's why our clients see maintenance costs[^3] drop by 60%. They are not just buying a valve. They are buying years of uninterrupted, reliable service.

| Lining Material | Key Strengths | Best For |

|---|---|---|

| PFA/PTFE | Exceptional chemical resistance[^5], high-temperature tolerance | Aggressive acids, alkalis, solvents, and disinfectants |

| ETFE | Good chemical resistance[^5], excellent mechanical toughness | Abrasive slurries with corrosive chemicals |

| EPDM Rubber | Good resistance to water treatment chemicals, flexible | General water, sludge, and mild chemical applications |

For the most demanding applications, like dosing concentrated sodium hypochlorite or sulfuric acid, a fluorine lining is the only way to guarantee a long, reliable service life. This is what we mean by a true "wastewater buster."

How does choosing the right supplier impact your project's success?

You've found the right type of valve, but your supplier causes delays. Inconsistent quality and poor communication are holding up your project. These supplier issues lead to budget overruns and missed deadlines.

The right supplier is more than a vendor; they are a partner. A reliable manufacturer guarantees consistent quality through strict controls, offers faster lead times (35-45 days vs. months), and provides end-to-end support, from design to mass production, ensuring your project's success.

I remember working with a client who was sourcing valves from another country. The lead times were a nightmare. A container would take 3-4 months to arrive. This created huge bottlenecks in their projects. When they switched to us, we cut that time down to 35-45 days. That’s a massive difference. Choosing a supplier isn't just about price. It's about total value. Here's what you should look for.

1. Manufacturing Process

Let's dig into our manufacturing. We use the resin-coated sand process for casting our valve bodies. This is a more advanced technique. It results in a much smoother surface finish and fewer casting defects. A flawless body provides a perfect base for the lining to adhere to. We also invest in all-new molds. This ensures every valve we produce has a perfect appearance. For brands and distributors, appearance is the first sign of quality. We make sure that first impression is excellent.

2. Quality Control

Our quality control is built into every step. We manage our supply chain for lining materials and source raw ductile and cast iron with strict oversight. This stability is how we can promise a 35-45 day lead time for a full container. Our robust process ensures speed without sacrificing quality. This reliability is crucial for our clients who need to manage their inventory and project timelines.

3. One-Stop Solution

Finally, let's talk about being a one-stop solution. A project manager doesn't want to source manual valves from one place and pneumatic ones from another. We provide both. They don't want to be limited in lining options. We offer a full range of rubber and plastic linings. And we handle all common flange standards—British PN, American ANSI 150, Australian TABLE D, and Chinese GB. This simplifies procurement. For businesses looking to develop their own brand, our full OEM/ODM service takes them from concept to mass production. We become a true partner, not just a supplier.

Conclusion

Choosing the right fluorine-lined diaphragm valve and a reliable supplier is key. It cuts costs, boosts efficiency, and ensures long-term success for your wastewater treatment projects.

[^1]: Explore how these valves can significantly reduce maintenance costs and improve operational efficiency. [^2]: Learn about the importance of corrosion resistance in extending the life of valves in harsh environments. [^3]: Discover effective strategies to minimize maintenance costs and enhance plant performance. [^4]: Understand the unique properties of PFA and PTFE that make them ideal for valve linings in aggressive environments. [^5]: Find out how chemical resistance can prevent leaks and failures in wastewater treatment systems. [^6]: Explore the significance of sodium hypochlorite in disinfection processes and its impact on valve selection.