Wastewater plants face corrosive chemicals and abrasive sludge daily. The wrong valve fails, causing costly downtime and safety hazards. Diaphragm valves are the robust solution for these demanding conditions.

Diaphragm valves are essential in wastewater treatment for controlling corrosive chemicals, regulating abrasive sludge flow[^1], and providing leak-proof sealing[^2]. Their unique design prevents contamination and clogging, ensuring efficient and reliable plant operation for processes like chemical dosing[^3], filtration[^4], and sludge handling[^5].

It's one thing to say they're effective, but how do they actually perform in specific applications? I've spent years helping plant managers solve their toughest fluid control problems, and the diaphragm valve is often the hero of the story. Let's break down their role in a typical wastewater treatment plant. Understanding these details will show you why they are the go-to choice for so many engineers and procurement managers looking for reliability.

How Do Diaphragm Valves Handle Corrosive Chemical Dosing?

Dosing aggressive chemicals like chlorine or acids can destroy standard valves quickly. Leaks are not just wasteful; they are a serious safety risk for your plant personnel and equipment.

Diaphragm valves handle corrosive chemicals[^6] by using inert rubber or plastic linings[^7]. The diaphragm completely isolates the chemical from the valve's moving parts. This design prevents corrosion and ensures precise, leak-free dosing for effective water purification and process control.

In my experience, chemical dosing[^3] is where many facilities first discover the power of a diaphragm valve. I remember a client whose team was replacing expensive alloy valves every few months on their sodium hypochlorite line. The constant leaks were a safety concern and a budget drain. We recommended a switch to our PTFE-lined diaphragm valves[^8]. After installation, their maintenance calls for that line dropped to zero. The valve simply worked, day in and day out. This is because the design is fundamentally superior for this task. The media only ever touches the valve body's lining and the diaphragm itself. Since these parts are made from highly resistant materials, the valve's core structure is permanently protected.

Choosing the Right Lining for Your Chemical

The key is selecting the correct lining material for the specific chemical you are handling. This is a critical decision we help our clients with every day. An incorrect choice can lead to premature failure, but the right one guarantees years of trouble-free service.

| Chemical Agent | Common Use in Wastewater | Recommended Lining | Why it Works |

|---|---|---|---|

| Sodium Hypochlorite | Disinfection | EPDM, PTFE | Excellent resistance to strong oxidizers. |

| Sulfuric Acid | pH Adjustment | PTFE, PFA | Virtually inert to a wide range of acids. |

| Ferric Chloride | Coagulation | EPDM, Natural Rubber | Good resistance to acidic salts and slurries. |

| Sodium Hydroxide | pH Adjustment | NBR, EPDM | Resists caustic solutions effectively. |

This precise material matching, combined with the valve's ability to throttle flow accurately, ensures that you use exactly the right amount of chemical. This improves treatment efficiency and saves a significant amount of money over time.

Why Are Diaphragm Valves Ideal for Sludge and Slurry Control?

Sludge and slurries are thick and abrasive. They can easily clog and wear down conventional valves like ball or gate valves, causing process interruptions and frequent, messy maintenance work.

Diaphragm valves are ideal for sludge because their smooth, pocketless flow path[^9] prevents solids from settling and causing blockages. The resilient diaphragm and robust lining also resist the abrasive wear from slurries, ensuring long service life and reliable flow control.

Think of it this way. A gate valve or ball valve has cavities and sharp corners where solids can get trapped. When you try to close the valve, this trapped debris can prevent a proper seal or even damage the valve itself. A diaphragm valve, especially a weir-type, has a smooth, contoured flow path. The fluid moves gently over a small "weir" or dam. There are no pockets or dead spots for solids to accumulate. When the valve closes, the diaphragm presses down onto this smooth weir, pushing any solids out of the way and creating a tight seal. I’ve seen this make a huge difference in primary treatment and dewatering applications, where solids content is very high. Plants that switch from other valve types to diaphragm valves report a dramatic reduction in downtime related to clogged lines.

Built to Withstand Abrasion

Beyond just preventing clogs, the valve has to survive the constant sand-paper-like effect of slurries. This is where material selection is once again crucial.

- Hard and Soft Natural Rubber Linings[^10]: These are excellent choices for abrasive media. They have a fantastic ability to absorb the impact of particles and resist being worn away.

- Isolated Components: The diaphragm protects the valve's stem and actuator from the abrasive flow. In other valve designs, the stem is often directly in the flow path, where it can be scored and damaged, leading to operational issues and leaks.

By combining a clog-resistant design with wear-resistant materials, diaphragm valves provide a far more reliable and low-maintenance solution for sludge and slurry lines than almost any other valve type. This translates directly to higher plant uptime and lower operational costs.

Can Diaphragm Valves Ensure System Integrity Under Pressure?

Pressure spikes and fluctuations are common in wastewater systems. These events can stress valve seals, leading to leaks that compromise system integrity and create potential safety hazards for workers.

Yes, diaphragm valves ensure system integrity by providing a positive, leak-proof seal. The flexible diaphragm presses firmly against the valve weir. This creates a bubble-tight shutoff that isolates the fluid from the environment, even with pressure fluctuations.

The sealing mechanism of a diaphragm valve is its greatest strength. Unlike other valves that rely on a disc or ball rotating against a seat—where wear can eventually cause a leak—the diaphragm valve's seal is different. The diaphragm is a flexible membrane that is pressed down onto the solid body of the valve. This creates a large sealing area and a very forgiving seal. It's not a metal-on-metal or plastic-on-metal contact point that can easily be damaged. This design provides what we call "Class VI" or bubble-tight shutoff. It means absolutely no fluid or gas can pass through when the valve is closed. For our clients, this provides peace of mind, especially in automated systems.

The Anatomy of a Perfect Seal

The reliability comes from a few key design features working together.

- Isolation of Working Parts[^11]: The diaphragm creates a static seal that separates the fluid from every other part of the valve. The stem, the bonnet, the actuator—none of it ever touches the process media. This means no corrosion of the operating mechanism, which is a common failure point in other valves. Your expensive pneumatic actuator is completely safe.

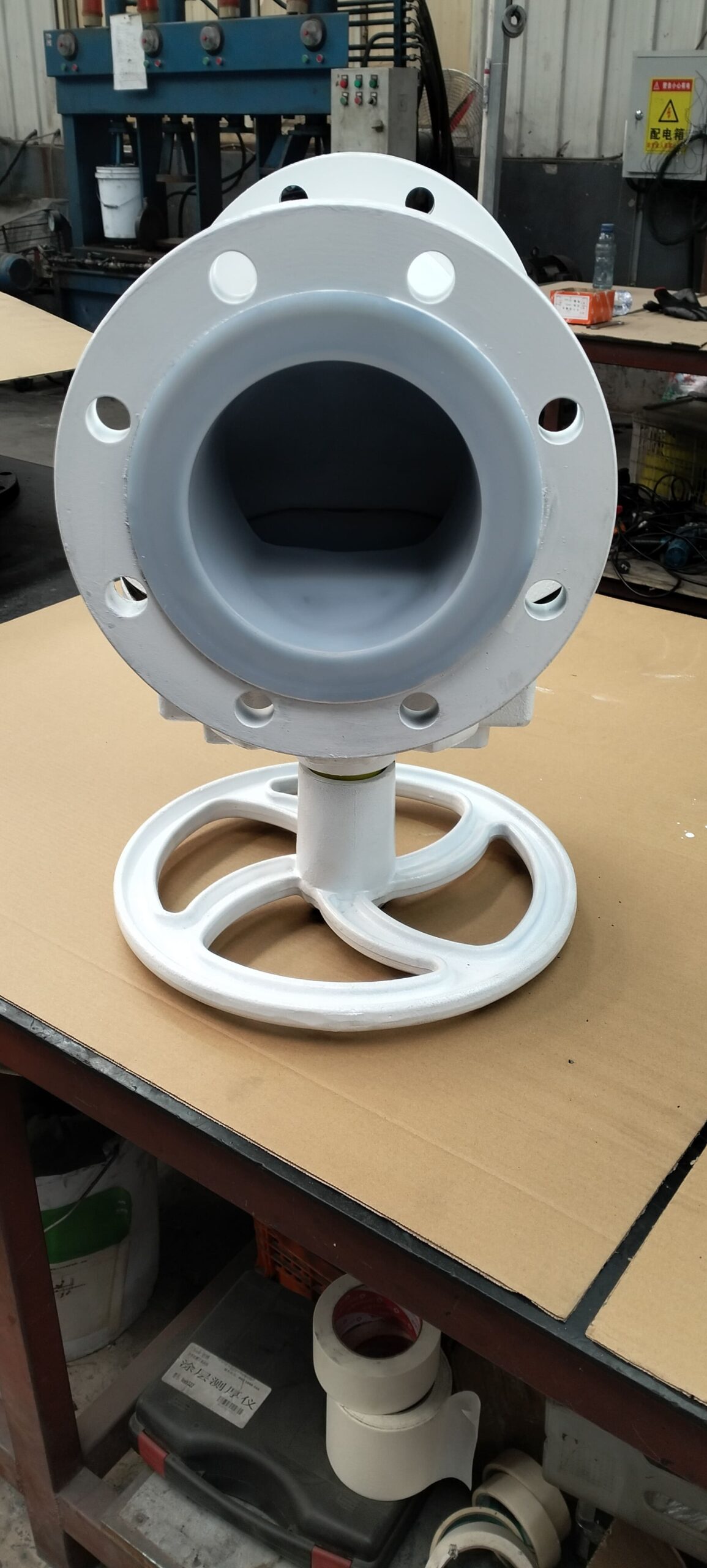

- Robust Body Construction[^12]: The pressure is contained by the valve body. Our valves use cast iron (CI) and ductile iron (DI) bodies made with a resin-coated sand process. This results in a stronger, smoother casting with fewer imperfections. It provides the structural integrity needed to handle system pressure safely.

- Secure Bonnet Assembly[^13]: The bonnet holds the diaphragm in place and is securely bolted to the body. This robust assembly ensures the diaphragm remains perfectly sealed to the body, even under pressure, preventing any external leaks.

This total isolation and robust construction mean the valve is inherently safe and reliable, making it a cornerstone of a well-designed wastewater treatment system.

Conclusion

Diaphragm valves are essential for wastewater treatment. They reliably control corrosive chemicals, abrasive slurries, and high-pressure lines, ensuring safety, efficiency, and long-term performance in the most demanding environments.

[^1]: Exploring how diaphragm valves manage abrasive sludge flow can reveal their effectiveness in preventing clogs and wear, ensuring reliable plant operation. [^2]: Discovering the leak-proof capabilities of diaphragm valves can assure system integrity, preventing leaks and maintaining safety under pressure. [^3]: Learning about diaphragm valves in chemical dosing can highlight their precision and reliability, crucial for effective water purification and process control. [^4]: Understanding diaphragm valves' role in filtration can enhance knowledge of their efficiency in preventing contamination and ensuring smooth operation. [^5]: Exploring diaphragm valves in sludge handling can demonstrate their ability to resist abrasion and prevent blockages, ensuring long service life. [^6]: Understanding how diaphragm valves handle corrosive chemicals can help ensure plant safety and efficiency, reducing costly downtime and hazards. [^7]: Investigating inert linings can reveal their importance in preventing corrosion and ensuring precise chemical dosing, enhancing valve longevity. [^8]: Understanding the advantages of PTFE-lined valves can show their resistance to strong oxidizers, reducing maintenance and safety concerns. [^9]: Exploring this design feature can demonstrate its effectiveness in preventing solids from settling, ensuring reliable flow control. [^10]: Investigating these linings can show their ability to absorb impact and resist wear, crucial for handling abrasive slurries. [^11]: Exploring this feature can show its importance in preventing corrosion and ensuring safe operation, protecting expensive components. [^12]: Understanding robust construction can reveal its role in handling system pressure safely, ensuring structural integrity and reliability. [^13]: Investigating the bonnet assembly can demonstrate its importance in maintaining a perfect seal, preventing external leaks under pressure.