Choosing the wrong valve for strong acids can lead to leaks and shutdowns. You need a reliable solution that won't fail. Which fluorine-lined valve is truly right for you?

For pure, highly corrosive liquids requiring a perfect seal, choose a fluorine-lined ball valve[^1]. For media with particles, slurries, or when you need flow control, the fluorine-lined diaphragm valve[^2] is the superior choice because its design prevents clogging and handles impurities effortlessly.

I’ve seen many clients struggle with this choice. A wrong decision can be costly, leading to downtime and safety hazards. But understanding the core differences makes the decision easy. Let's break down each valve type to see which one fits your specific needs.

When is a Fluorine-Lined Ball Valve the Undisputed Champion?

Worried about hazardous leaks with pure acids? A tiny drip can cause major problems. You need a valve that guarantees a perfect, bubble-tight seal every single time.

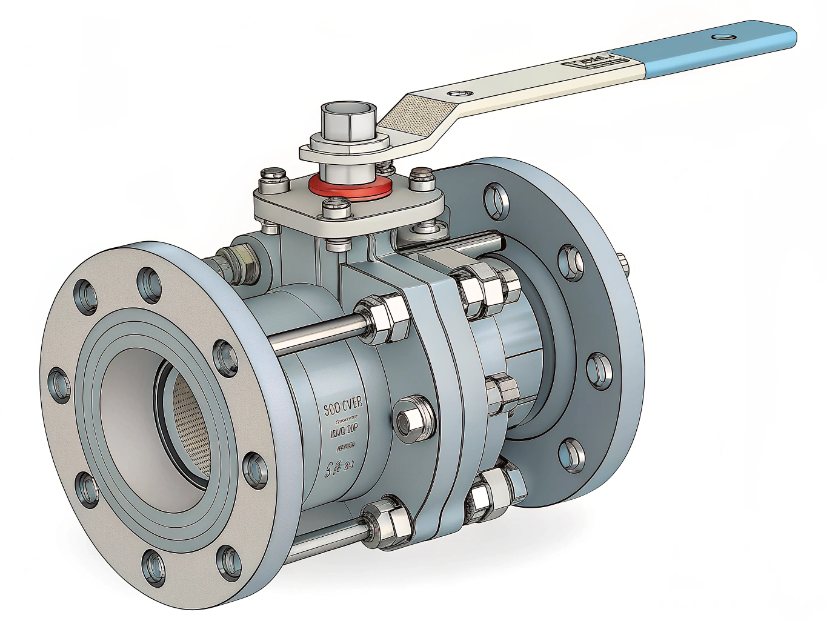

A fluorine-lined ball valve[^1] is your best bet for clean, highly corrosive media like pure sulfuric acid[^3] or chlorine gas. Its rotating ball design provides a tight mechanical seal, ensuring zero leakage[^4] and maximum safety in critical applications where purity and containment are non-negotiable.

A fluorine-lined ball valve[^1] operates with a simple, effective mechanism. A ball with a hole through it rotates to open or close the flow path. When closed, the solid part of the ball presses tightly against the valve seats. This creates an incredibly strong mechanical seal. That's why we recommend it for applications demanding zero leakage[^4]. Think of handling pure sulfuric acid[^3], hydrochloric acid, or chlorine gas. In these scenarios, any leak is a major safety and environmental risk. The ball valve’s tight shut-off gives you peace of mind.

However, this design has a weakness. There is a small space, or dead cavity, between the ball and the valve body. If your media contains solid particles or is sticky, these impurities can get trapped in this space. This can cause two big problems. First, the particles will grind against the sealing surfaces, causing wear and eventually leading to leaks. Second, enough buildup can jam the ball, making the valve difficult or impossible to operate.

Key Characteristics of Fluorine-Lined Ball Valves

| Feature | Description |

|---|---|

| Sealing Mechanism | Rotating ball against a seat |

| Best For | Pure, clean, highly corrosive liquids & gases |

| Key Advantage | Zero leakage, tight shut-off |

| Main Weakness | Susceptible to particles and slurries |

| Common Failure Mode | Trapped debris causing seat wear or jamming |

Why is a Fluorine-Lined Diaphragm Valve the Go-To for "Dirty" Jobs?

Are particles and slurries wrecking your valves? Constant clogging and maintenance are costly. You need a valve designed to handle tough, abrasive media without failing.

The fluorine-lined diaphragm valve[^2] excels with abrasive or particle-laden media. Its flexible diaphragm isolates the fluid from all moving parts, eliminating clogging risks. This makes it perfect for wastewater, slurries, and chemical sludge where other valves would quickly jam and fail.

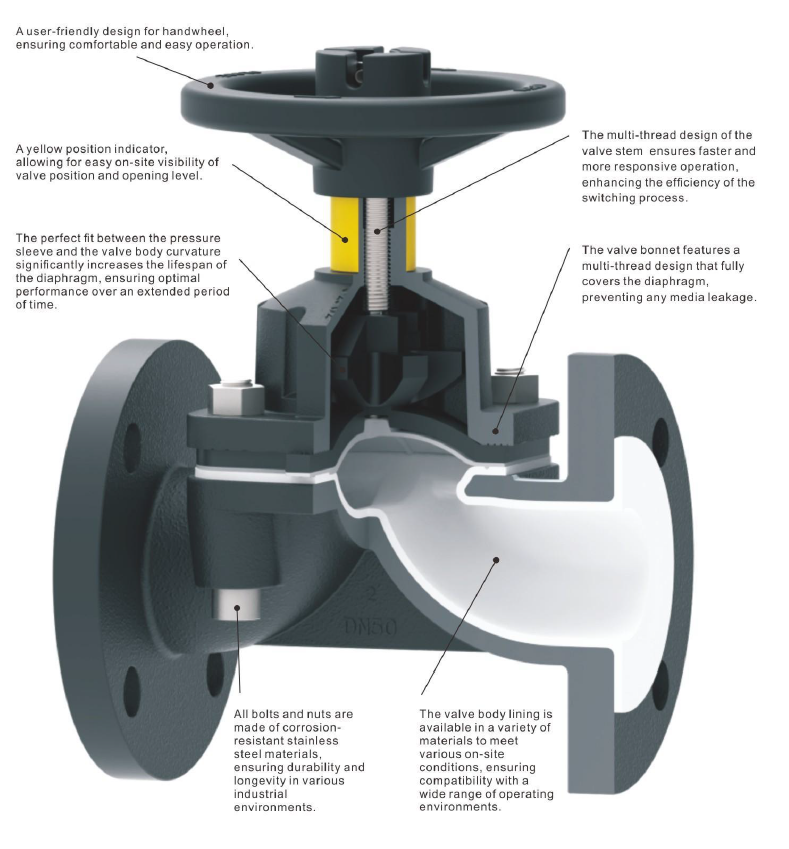

A fluorine-lined diaphragm valve[^2] works completely differently. It uses a flexible diaphragm that presses down onto a weir (a raised ridge in the valve body) to stop the flow. The fluid never touches the valve's bonnet or actuator. This design has a huge advantage: there are no dead cavities where particles can get stuck. Impurities in the media simply flow through with the rest of the liquid. This makes it the perfect choice for "dirty" and tough jobs. We often supply these valves for handling phosphoric acid with particles, sodium hydroxide waste with suspended solids, or thick chemical sludge. The valve just keeps working, no matter how messy the media is.

Another great feature is its ability to regulate flow. Because the diaphragm can be positioned anywhere between fully open and fully closed, it provides excellent throttling control, especially in low-pressure systems. This is ideal for applications like wastewater treatment plants, where you need to precisely dose chemicals or manage the flow of sludge. It's the reliable workhorse for jobs that other valves can't handle.

Key Characteristics of Fluorine-Lined Diaphragm Valves

| Feature | Description |

|---|---|

| Sealing Mechanism | Flexible diaphragm pressing against a weir |

| Best For | Corrosive media with solids, slurries, viscous fluids |

| Key Advantage | No dead cavities, glandless, clog-resistant |

| Main Weakness | Limited to lower pressures and temperatures |

| Common Use Case | Dosing, flow regulation in wastewater treatment |

Conclusion

For pure corrosives, choose a ball valve's tight seal. For dirty, abrasive media, a diaphragm valve's clog-proof design is unbeatable. Making the right choice ensures reliability.

[^1]: Explore the advantages of fluorine-lined ball valves for handling corrosive media safely and effectively. [^2]: Learn how diaphragm valves excel in managing abrasive media and preventing clogging. [^3]: Understand the critical safety protocols when working with highly corrosive substances like sulfuric acid. [^4]: Discover the technologies that guarantee zero leakage in critical applications for enhanced safety.