Struggling to choose between ETFE and PFA linings? The wrong choice can lead to valve failure and costly downtime. We help you find the perfect match for your application.

Choose ETFE for its mechanical strength and abrasion resistance in industries like mining. Select PFA for superior chemical and temperature resistance, especially with aggressive acids and solvents. Both offer excellent protection, but the right choice depends on your specific application.

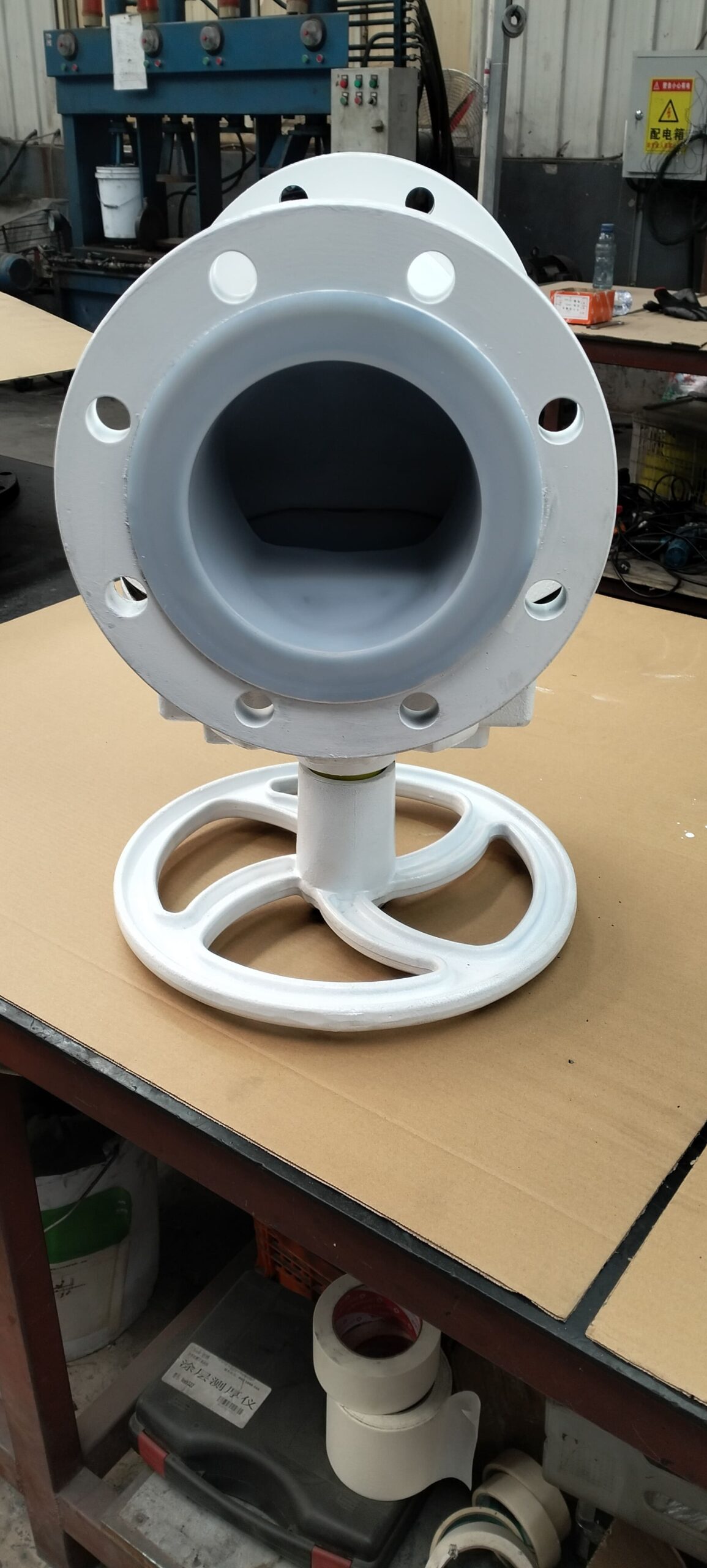

Choosing the right lining for a diaphragm valve is a critical decision. It directly impacts the valve's lifespan, performance, and safety. Recently, our team at STABLE VALVES delivered a large batch of DN150 ETFE-lined diaphragm valves[^1]. This project was for a client who needed top-tier chemical resistance combined with durability. This experience really highlighted how important it is to understand the differences between high-performance materials like ETFE and PFA. Making the right choice isn't just about picking a material; it's about matching the material's strengths to your specific industrial challenge.

What makes ETFE the go-to for durability?

Need a valve lining that withstands rough handling and abrasive materials? ETFE offers a tough, cost-effective solution that protects your investment from mechanical wear and tear.

ETFE (Ethylene-tetrafluoroethylene) is your best choice for durability. Its superior mechanical strength and abrasion resistance make it ideal for mining, water treatment, and chemical applications where physical toughness is as important as chemical resistance.

When we talk about ETFE, the first word that comes to my mind is "tough." This material is a workhorse. It has fantastic mechanical properties that make it stand out. Think of applications where the fluid isn't just corrosive but also contains abrasive particles, like slurries in mining or grit in wastewater treatment. This is where ETFE really shines. Its surface is hard and resistant to being worn away. This means the valve and its lining last much longer, even under constant physical stress.

A Deeper Look at ETFE's Strengths

ETFE offers a balanced profile of properties, making it a very versatile and cost-effective choice for many industries.

- Mechanical Toughness: ETFE is significantly stronger and stiffer than PTFE. It has a higher tensile strength and is more resistant to cuts and abrasion. This makes it perfect for slurries or environments where the valve might face external impacts.

- Chemical Resistance: While not quite at the same level as PFA, ETFE still boasts excellent resistance to a wide range of chemicals, acids, and solvents. For many standard chemical processing applications, its resistance is more than enough.

- Cost-Effectiveness: ETFE is often a more economical option than PFA. When an application demands good chemical resistance and high mechanical durability, ETFE provides a great performance-to-cost ratio.

| Feature | ETFE (Ethylene-tetrafluoroethylene) |

|---|---|

| Primary Advantage | Mechanical strength and abrasion resistance |

| Best For | Abrasive slurries, high-impact environments, general chemical use |

| Common Industries | Mining, Water Treatment, Power Plants (ash handling) |

| Temperature Limit | Approx. 150°C (302°F) |

| Cost | More economical than PFA |

This combination of toughness, good chemical resistance, and value makes ETFE an ideal choice for a huge number of industrial flow control systems.

When is PFA the non-negotiable choice for safety and performance?

Are extreme temperatures and highly corrosive chemicals compromising your system? PFA linings provide unmatched resistance, ensuring safety and reliability when other materials might fail.

PFA (Perfluoroalkoxy) is essential for extreme conditions. It handles a wider temperature range and offers superior resistance to aggressive chemicals like strong acids and solvents. Choose PFA for critical applications where purity and performance are paramount.

If ETFE is the tough workhorse, then PFA is the high-performance specialist. There are some applications where you simply cannot compromise on chemical resistance or temperature stability. Think of handling concentrated sulfuric acid, hot solvents, or high-purity chemicals where any contamination is a disaster. In these situations, PFA is not just a good choice; it's often the only choice. I've seen cases where using a lesser material led to rapid failure, leaks, and dangerous situations. PFA provides that extra layer of security. Its molecular structure is very similar to PTFE (the material in Teflon), giving it near-universal chemical inertness, but it's melt-processable, which allows us to create a thick, uniform, and non-porous lining inside the valve.

Diving into PFA's Superior Properties

PFA's capabilities are most apparent in the most demanding environments. It's designed for situations where failure is not an option.

- Ultimate Chemical Resistance: PFA is resistant to virtually all chemicals, even at high temperatures. This includes aggressive acids, bases, and organic solvents that would degrade other plastics and even some metals. This makes it ideal for multi-purpose chemical plants where the media flowing through the pipes can change.

- High-Temperature Stability: PFA can operate continuously at temperatures up to 260°C (500°F). This is a significant step up from ETFE and makes it suitable for high-temperature chemical reactions and processing.

- Purity and Smoothness: PFA linings have an incredibly smooth surface. This reduces friction, prevents buildup of media, and makes it easy to clean. It is also extremely low in extractables, meaning it won't leach impurities into the process fluid. This is vital for the pharmaceutical and semiconductor industries.

| Feature | PFA (Perfluoroalkoxy) |

|---|---|

| Primary Advantage | Superior chemical and temperature resistance |

| Best For | Highly corrosive chemicals, high-purity applications, high temps |

| Common Industries | Chemical Processing, Pharmaceutical, Semiconductor, Petrochemical |

| Temperature Limit | Approx. 260°C (500°F) |

| Cost | Higher than ETFE, justified by performance |

When your application involves extreme chemistry, high heat, or a need for absolute purity, investing in a PFA-lined valve is the safest and most reliable long-term solution.

How does the lining process itself impact valve quality?

Is your valve lining prone to peeling, cracking, or voids? Poor application can ruin even the best material. Our process ensures a flawless, seamless lining for maximum performance.

Our mechanically applied linings are a game-changer. This process creates a seamless, smoother, and visually superior finish compared to traditional methods. It eliminates voids and weak spots, ensuring a reliable barrier and extending valve life.

Choosing between ETFE and PFA is only half the battle. The way the lining is applied to the valve body is just as important. A great material applied poorly will fail. At STABLE VALVES, we have invested heavily in our manufacturing process to solve this exact problem. We use a method of mechanically applying our linings. This is different from many other manufacturers. This technique ensures the lining material is perfectly bonded to the metal valve body without any tiny air gaps or voids. A void, no matter how small, can become a weak point where corrosion starts. Our process also results in a lining that is incredibly smooth and has a uniform thickness throughout the valve. This smooth flow path prevents material from building up and reduces pressure drop in your system.

The STABLE VALVES Advantage in Manufacturing

Our commitment to quality goes beyond just the materials we select. It's built into every step of how we make our valves.

- Superior Casting: It all starts with a better valve body. We use a resin-coated sand casting process. This creates a valve body with a much smoother surface and far fewer imperfections than traditional sand casting. A better surface means the lining adheres better.

- All-New Molds: We use all-new molds for our valve bodies. This might seem like a small detail, but it means our valves have a flawless appearance and consistent dimensions. There are no blemishes or defects that could compromise the lining.

- Mechanically Applied Linings: This is our key advantage. The result is a lining that is seamless, visually perfect, and mechanically robust. It is far less likely to peel, crack, or fail over time compared to other application methods.

This focus on manufacturing excellence means that when you get a valve from us, you're not just getting a piece of equipment. You're getting a fully engineered solution designed for reliability and a long service life.

Conclusion

Choosing the right lining, ETFE or PFA, is crucial. We provide high-quality, expertly manufactured lined valves to ensure your system's reliability and long life. Contact us for your needs.

[^1]: Discover the applications and benefits of using DN150 ETFE-lined diaphragm valves in industrial settings.