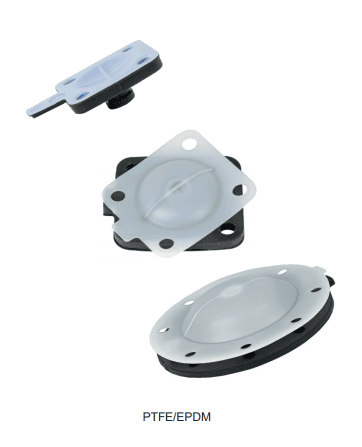

Choosing the wrong diaphragm material[^1] can lead to leaks and costly downtime. You need a reliable seal for your specific application, but material specifications can be confusing.

For diaphragm valves, use EPDM[^2] for its flexibility[^3] with water-based media like in water treatment[^4]. Choose PTFE[^5] for its superior chemical resistance in corrosive or high-purity applications, such as chemical processing and pharmaceuticals. This choice ensures optimal performance and longevity for your valve.

Understanding the basic differences is a great start. But the real decision comes down to the specific valve type and its application. Let's look at how EPDM[^2] and PTFE[^5] perform in different valve configurations to help you make the best choice for your business.

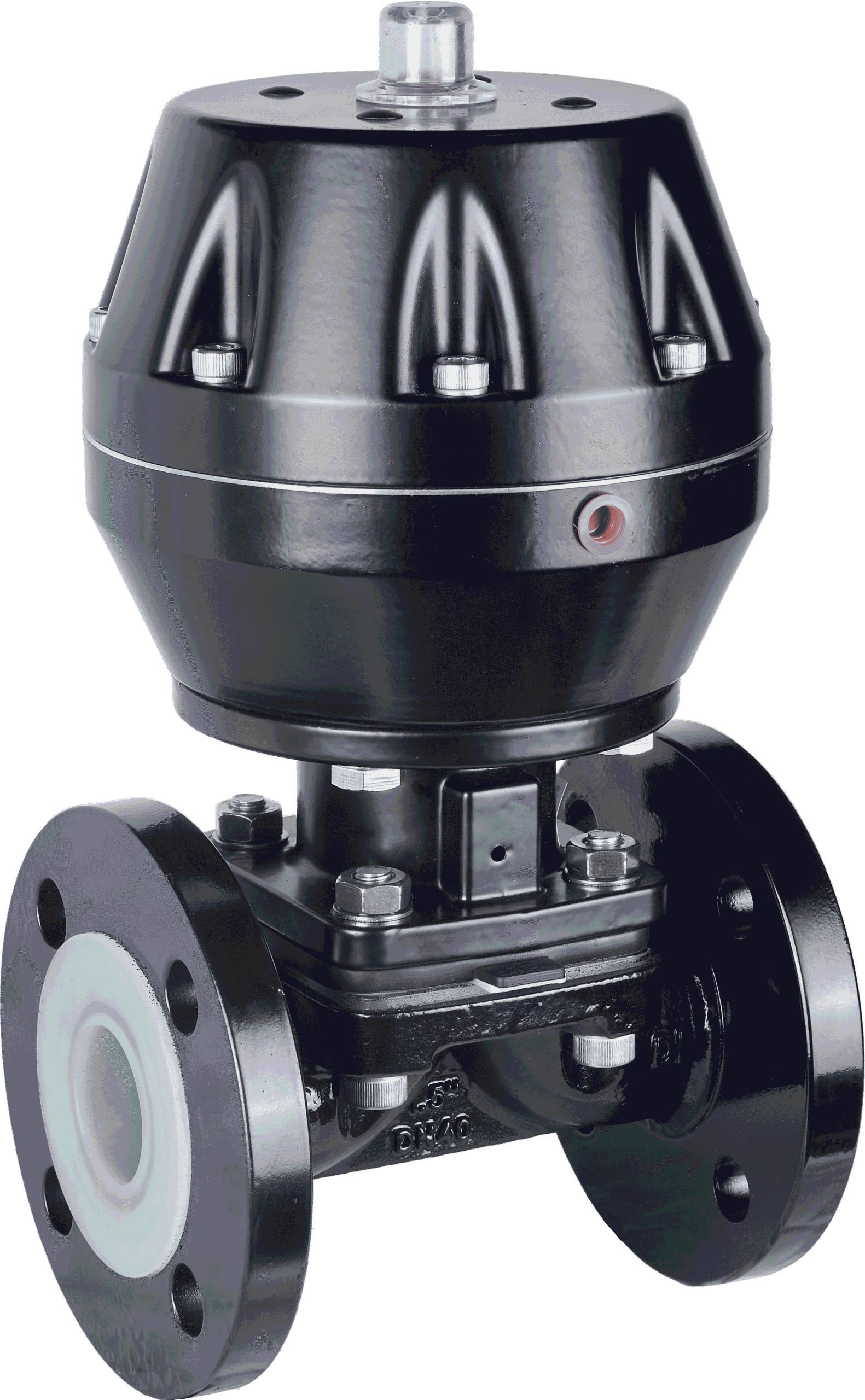

How do EPDM[^2] and PTFE[^5] perform in pneumatic diaphragm valves[^6]?

Automated systems demand precision and reliability. A material failure in a pneumatic valve can disrupt your entire process. You need a diaphragm that performs flawlessly under constant actuation.

In pneumatic diaphragm valves[^6], EPDM[^2] is ideal for water treatment[^4] and non-corrosive media due to its flexibility and durability. PTFE[^5] is essential for handling aggressive chemicals or maintaining sterile environments in pharmaceutical and chemical processing, offering unmatched chemical resistance and long service life.

When we look at pneumatic diaphragm valves[^6], the choice between EPDM[^2] and PTFE[^5] becomes critical because of the demands of automation. These valves are the workhorses in automated processes for a reason—they offer precise control. The diaphragm material[^1] must support this function without fail.

The Impact of Automation

In an automated system, valves may cycle thousands of times a day. EPDM[^2]'s excellent flexibility makes it a great choice for high-cycle applications involving water or other non-corrosive fluids. It responds well to the constant movement driven by the pneumatic actuator. PTFE[^5], while more rigid, provides unmatched durability against harsh chemicals. In our manufacturing process, we often use a two-piece diaphragm design with a PTFE[^5] face and an EPDM[^2] backing. This combines PTFE[^5]'s chemical inertness with EPDM[^2]'s flexibility, creating a robust solution for automated chemical dosing.

Material Performance Breakdown

Here's a simple breakdown for pneumatic valves:

| Feature | EPDM[^2] | PTFE[^5] |

|---|---|---|

| Primary Use | Water, non-corrosive fluids, slurries | Aggressive chemicals, high-purity media |

| Flexibility | High | Moderate (often requires backing) |

| Chemical Resistance | Good | Excellent |

| Typical Industry | Water Treatment, Power Plants | Chemical, Pharmaceutical, Biotech |

I've seen clients in chemical processing rely exclusively on our PTFE[^5]-lined pneumatic valves for their automated dosing systems. This prevents any chemical attack on the valve components, ensuring process integrity and safety.

What's the best material for multi-port diaphragm valves[^7]?

Complex fluid paths create more chances for failure. Managing multiple flows with one valve is efficient, but choosing the wrong diaphragm material[^1] can compromise the entire system.

For multi-port diaphragm valves[^7], EPDM[^2] is a cost-effective choice for general-purpose applications like water distribution, offering good flexibility. PTFE[^5] is necessary for high-purity or corrosive applications in pharma and biotech, where it prevents cross-contamination and ensures chemical compatibility.

Multi-port valves are brilliant for simplifying complex piping systems. Instead of using multiple two-way valves, a single multi-port valve can direct, mix, or divert different fluids. This efficiency, however, places a huge responsibility on the diaphragm material[^1].

Simplifying Fluid Paths

The main benefit of a multi-port valve is reducing system footprint and eliminating "dead legs"—sections of pipe where fluid can stagnate. This is crucial in industries like pharmaceuticals where bacterial growth is a major concern. The diaphragm material[^1] must not only handle the media but also maintain a perfect seal across different ports. For a water treatment plant's sampling station, an EPDM[^2] diaphragm is perfectly suitable. It's durable enough to handle the constant switching between lines.

Preventing Cross-Contamination

In high-purity or chemical applications, preventing cross-contamination is the top priority. PTFE[^5] is the only choice here. Its non-stick, inert surface ensures that no residue from one fluid contaminates another.

| Factor | EPDM[^2] in Multi-Port Valves | PTFE[^5] in Multi-Port Valves |

|---|---|---|

| Function | Fluid distribution in non-critical systems | Mixing, sampling, diverting in high-purity or corrosive systems |

| Contamination Risk | Low (for compatible media) | Extremely Low (chemically inert) |

| Advantage | Cost-effective and flexible | Prevents cross-contamination, ensures purity |

I remember a client in the biotech space who switched to our PTFE[^5]-lined multi-port valves for their purification process. They were able to simplify their skid design, reduce the system footprint, and most importantly, ensure zero cross-contamination between their buffer solutions. For high-value media, the chemical inertness of PTFE[^5] is non-negotiable.

Which material should you choose for 3-way diaphragm valves[^8]?

Managing flow diversion or mixing in a single valve body is efficient. But a diaphragm failure can lead to incorrect mixing or process contamination, causing major production issues.

In 3-way diaphragm valves[^8], EPDM[^2] diaphragms are reliable and economical for non-corrosive fluid applications like HVAC and general water services. For corrosive chemicals, high-purity systems, or applications requiring fluid isolation, PTFE[^5] diaphragms are the superior choice due to their inertness and durability.

A 3-way diaphragm valve is a versatile tool for controlling flow paths. It can mix two fluids into one, divert one flow to two different outlets, or switch between two different sources. The diaphragm is central to all these functions, acting as the gatekeeper that directs the flow. The material you select must match the task at hand.

Core Functions of 3-Way Valves

The function of the valve directly informs the material choice. For diverting flow in a water cooling loop or a basic water treatment process, an EPDM[^2] diaphragm is a fantastic, reliable option. It’s flexible, seals well, and is very cost-effective. However, when a customer needs to mix an acid and a base for pH neutralization, EPDM[^2] would quickly degrade. In that scenario, PTFE[^5] is required to withstand the corrosive nature of both chemicals.

Material Suitability Matrix

Here’s how the materials stack up for common 3-way valve functions:

| Function | Recommended Material | Why? |

|---|---|---|

| Diverting Water | EPDM[^2] | Excellent flexibility and water resistance. |

| Mixing Chemicals | PTFE[^5] | Unmatched chemical resistance prevents degradation. |

| Isolating High-Purity Lines | PTFE[^5] | Inert surface prevents contamination between lines. |

| Sludge Line Control | EPDM[^2] | Good abrasion resistance and cost-effective for non-corrosive slurries. |

As a manufacturer, I've worked with many wastewater treatment plants that use our 3-way valves with EPDM[^2] diaphragms for sludge lines but switch to PTFE[^5]-lined ones for their chemical dosing stations. The material choice directly aligns with the media's properties to ensure safety and long-term reliability.

Conclusion

Choosing between EPDM[^2] and PTFE[^5] depends on your application's media, temperature, and purity requirements. Aligning the material with the valve type ensures optimal performance and system longevity.

[^1]: Explore this link to understand the importance of selecting the right diaphragm material for your specific application. [^2]: Learn about EPDM's flexibility and durability, making it ideal for water treatment and non-corrosive applications. [^3]: Learn about the importance of flexibility in diaphragm materials for various applications. [^4]: Explore best practices in water treatment to ensure effective and safe operations. [^5]: Discover why PTFE's chemical resistance is crucial for handling aggressive chemicals in various industries. [^6]: Gain insights into the functionality and importance of pneumatic diaphragm valves in automated systems. [^7]: Explore the efficiency and benefits of using multi-port diaphragm valves in complex piping systems. [^8]: Discover the versatility and applications of 3-way diaphragm valves in controlling flow paths.