A failed diaphragm can halt production, causing costly downtime and safety hazards. Are you risking your entire operation by guessing when to perform maintenance? Let’s change that.

You should replace a diaphragm based on a regular schedule (e.g., every 6 months for high-use cases), immediately upon signs of leaks or contamination, or if it fails a visual inspection for damage like cracks, deformation, or corrosion. Proactive replacement prevents unexpected failures.

Should You Follow a Strict Replacement Schedule?

Waiting for a valve to fail before acting is a gamble. This reactive approach can lead to sudden, expensive shutdowns. A proactive replacement schedule puts you in control.

Yes, a strict replacement schedule is highly recommended, especially in demanding applications. For high-temperature, high-frequency use, inspect every six months. For critical systems like chemical dosing, consider replacing the diaphragm after every production batch to ensure maximum reliability and safety.

Assessing Your Operating Conditions

Think about the four key factors: media, temperature, pressure, and cycle frequency. Abrasive slurries, aggressive chemicals, high temperatures, and frequent opening/closing all accelerate wear. For instance, in a power plant's flue gas desulfurization system, the diaphragm faces both abrasion from limestone slurry and chemical corrosion. This is a severe service application. In contrast, a valve in a wastewater treatment plant's final effluent line has a much easier life.

Creating a Custom Schedule

| Based on your assessment, you can build a custom schedule. Here is a simple guide I share with our partners to help them get started: | Service Condition | Recommended Action | Frequency |

|---|---|---|---|

| High-Risk / Severe Service | Full Replacement | Every Production Batch or 3 Months | |

| (e.g., Critical Dosing, Hot Acid) | |||

| High-Frequency / High-Temp | Inspect & Replace if Needed | Every 6 Months | |

| (e.g., Frequent Process Control) | |||

| Standard Service | Inspect & Replace if Needed | Annually | |

| (e.g., Water Lines, Low-Cycle Use) |

Start with a conservative schedule. Over time, you can adjust it based on the condition of the diaphragms you inspect. This data-driven approach is the most reliable way to optimize performance and prevent failures.

What Signs Demand an Immediate Diaphragm Replacement?

A diaphragm can fail unexpectedly, even with a maintenance schedule. Ignoring the early warning signs can lead to dangerous leaks and product contamination. Know what to look for.

Replace the diaphragm immediately if you notice any leaks or drips from the valve. Other critical signs include product contamination, process deviations, or finding out the diaphragm's shelf life (e.g., 5 years for EPDM) or service life has been exceeded.

The Unmistakable Sign: Leaks

The core design of a diaphragm valve is to be leak-proof to the outside environment. The diaphragm isolates the process fluid from the valve's bonnet and the atmosphere. If you see any weeping, dripping, or seepage from the bonnet area, it means the diaphragm has been breached. This is not a minor issue; it's a critical failure. The valve must be taken out of service and the diaphragm replaced right away to prevent safety hazards and environmental contamination.

The Silent Threat: Contamination

Sometimes, the failure isn't a leak to the outside, but a compromise of the process itself. If your process experiences unexpected contamination or a batch goes bad, a failing diaphragm could be the culprit. Small pinholes or delamination can trap and release old material, or particles from the diaphragm itself can shed into the fluid stream. If you suspect contamination, the diaphragm valve should be a primary component to inspect.

The Hidden Danger: Expiry Dates

Many people don't realize that diaphragm materials[^1], especially elastomers like EPDM or NBR, have a shelf life. Over time, the rubber loses its elasticity and chemical resistance, even when sitting in a box. I always advise our clients to follow the "first in, first out" rule for spare parts. An EPDM diaphragm, for example, should not be stored for more than five years or used for more than three years, even in light service. Installing an expired diaphragm, even if it looks new, is asking for a premature failure.

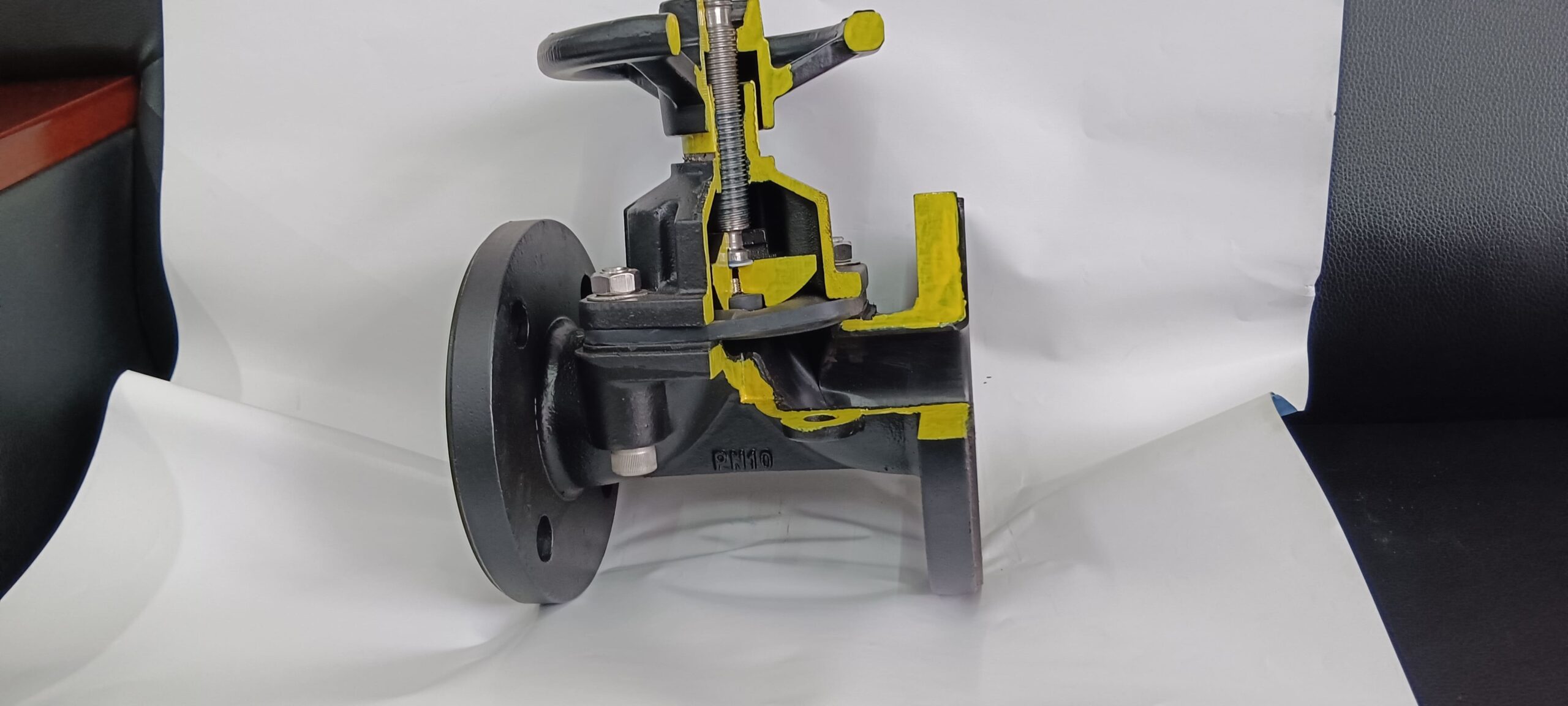

How Can You Visually Inspect a Diaphragm for Failure?

You've disassembled the valve for inspection. Is the diaphragm still usable or a failure waiting to happen? Reinstalling a bad part just delays the inevitable shutdown.

Look for physical damage. Telltale signs of failure include cracks, hardening, or obvious indentations that don't spring back. Also check for blistering, delamination, discoloration, or any embedded particles. If you see any of these, the diaphragm must be replaced.

Visual Inspection Checklist for Diaphragms

| | Failure Category | Visual Signs | What It Means |

|---|---|---|---|

| Deformation & Aging | Obvious indentation from the weir, hardening, loss of elasticity, whitening, surface cracks. | The material has reached the end of its physical life due to compression and age. It can no longer create a proper seal. | |

| Damage & Contamination | Delamination (layers peeling apart), bubbles or blisters under the surface, "fish-scale" patterns, embedded particles. | This indicates a breakdown in the material structure, often due to chemical attack or improper pressure/temperature conditions. | |

| Corrosion & Chemical Attack | Swelling or softening of the material, severe thinning, discoloration, blistering. | The diaphragm material is not compatible with the process fluid. It has been chemically compromised and is structurally weak. |

Always clean the diaphragm gently before inspection to ensure you can see the surface clearly. Bending it slightly can help reveal small cracks that are not visible when it's flat. This simple, hands-on check is one of the most effective maintenance procedures you can perform.

Conclusion

Regular inspections, knowing the warning signs, and following a smart replacement schedule are crucial. Remember, the safety and efficiency of your entire system can depend on a single diaphragm.

[^1]: Knowing diaphragm materials helps in selecting the right components for your specific applications.