Struggling with valves that leak, corrode, or contaminate your process fluids? This constant battle leads to downtime and safety risks. But one brilliant design solved it all.

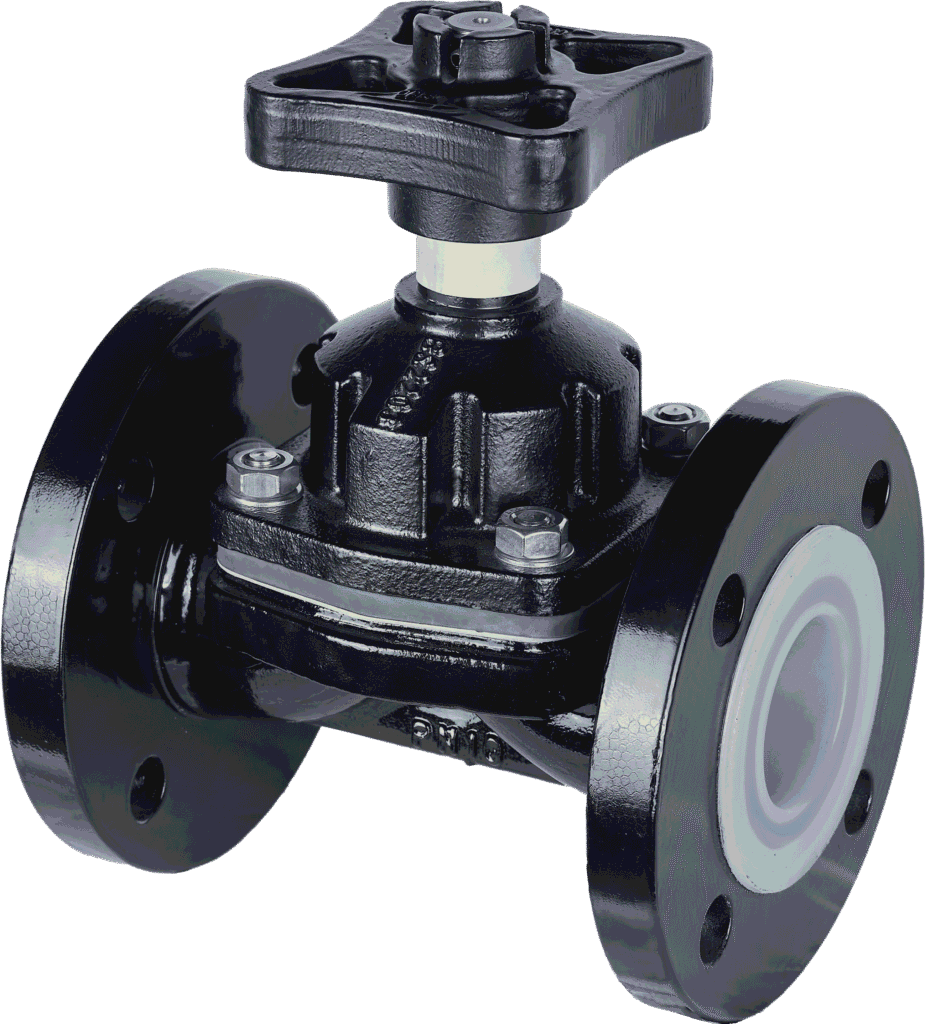

The genius of the diaphragm valve[^1] inventor was creating a simple, leak-proof design[^2]. A flexible diaphragm[^3] isolates the fluid from all moving parts, preventing stem leaks[^4], protecting the mechanism from corrosion, and ensuring the purity of the medium. This makes it perfect for tough industrial applications.

This simple idea completely changed how we handle difficult fluids. It was a departure from every valve that came before it. I've been in this business for years, and the elegant simplicity of the diaphragm valve[^1] still impresses me. But what exactly makes this design so superior for specific industries? Let's break down its core advantages.

How Does a Diaphragm Valve's Unique Structure Prevent Leaks and Contamination?

Stem leaks are a constant headache with other valves, causing safety risks and product loss. Imagine hazardous chemicals dripping out or your pure product getting contaminated by lubricants from the valve's mechanics.

A flexible diaphragm[^3] creates a solid, leak-proof barrier between the fluid and the valve's operating mechanism. This total isolation is the key. It ensures the media stays pure and completely prevents external leakage through the stem, a common failure point in other valve types.

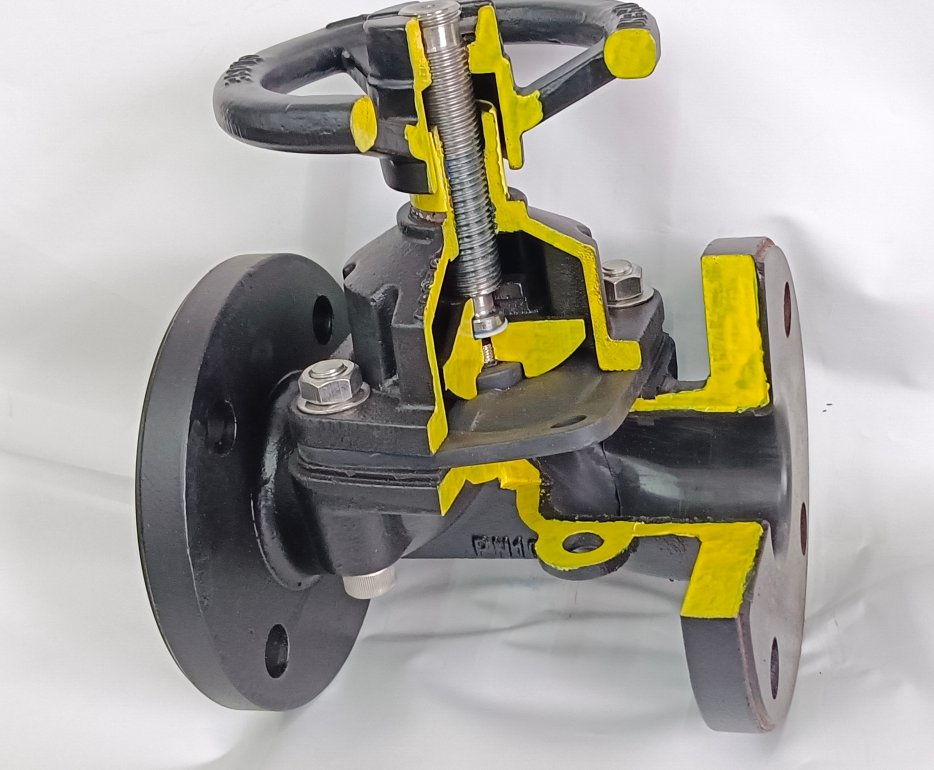

The design is brilliantly simple. A diaphragm valve[^1] has only three main parts: the valve body, the bonnet assembly, and the diaphragm itself. The diaphragm, a flexible membrane, is securely clamped between the body and the bonnet. When the valve is operated, a compressor in the bonnet assembly presses the diaphragm against a weir (a dam) in the valve body to stop the flow. The fluid never touches the stem, the threads, or any part of the operating mechanism.

I remember a client in the chemical industry who was constantly dealing with acid leaks from their old gate valves. The stem packing would degrade and fail regularly. When we switched them to our diaphragm valve[^1]s, the problem disappeared overnight. It’s a perfect example of how this glandless design provides total peace of mind.

Here is a simple comparison:

| Feature | Diaphragm Valve | Traditional Valve (e.g., Globe) |

|---|---|---|

| Stem Sealing | Glandless; sealed by the diaphragm | Requires gland packing around the stem |

| Leak Path | No path from fluid to atmosphere | Potential leak path along the stem |

| Media Purity | High; media never touches lubricants | Risk of contamination from packing/lubricants |

| Maintenance | Simple diaphragm change | Requires repacking the gland |

This fundamental difference is why diaphragm valve[^1]s are the default choice in so many applications where purity and safety are non-negotiable.

Why Is This Valve the Perfect Choice for Corrosive and Abrasive Fluids?

Aggressive chemicals and abrasive slurries[^5] can destroy standard metal valves in no time. This means frequent, expensive valve replacements and the constant threat of system failures and hazardous spills.

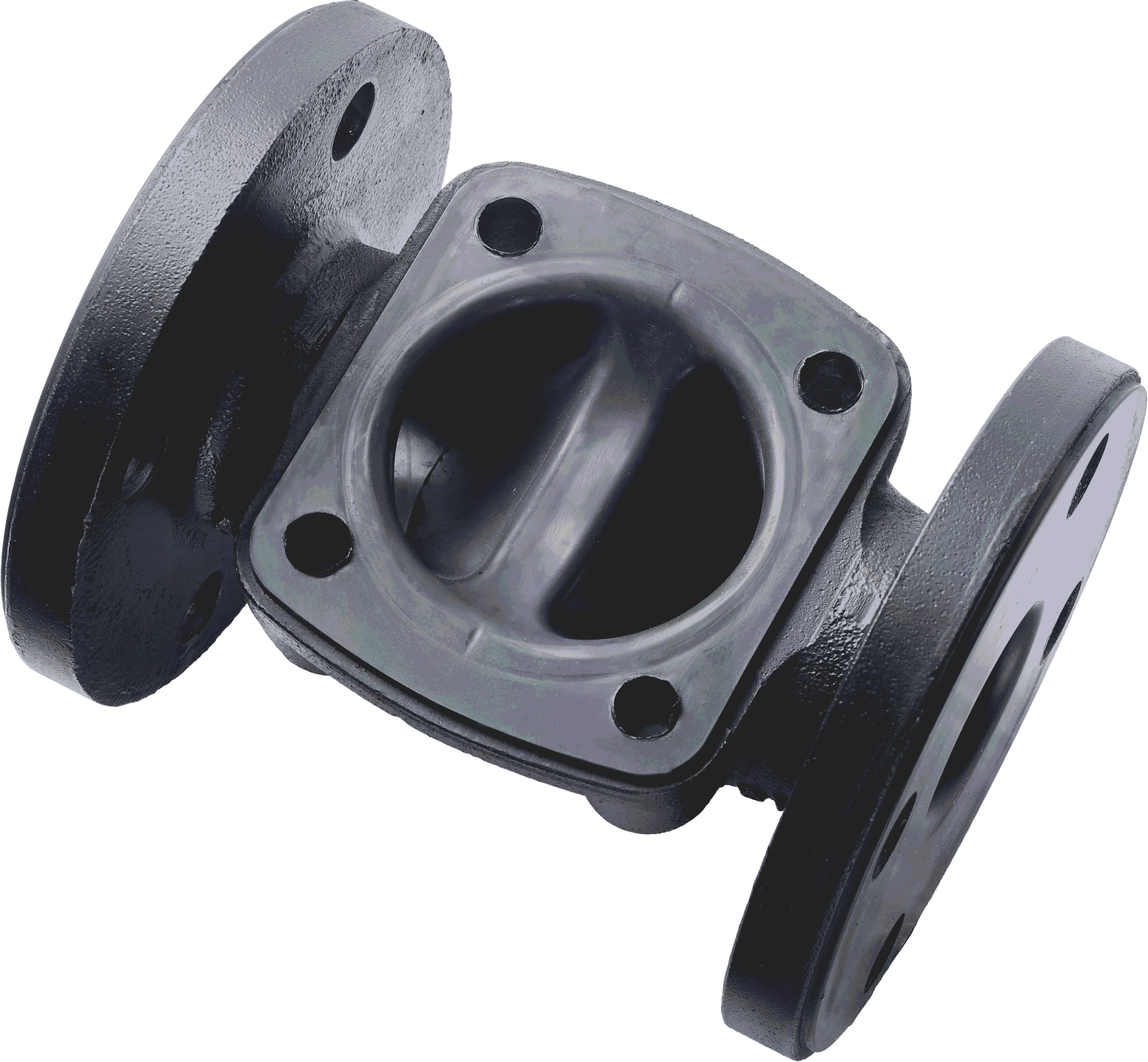

The fluid only ever touches two parts: the valve body lining and the diaphragm. We can make these from a huge range of corrosion-resistant plastics[^6] like PTFE or abrasion-resistant rubbers. This protects the valve's metal body and makes it ideal for handling aggressive media.

This is where the design's flexibility really shines. The main body of the valve, which provides the strength, can be made from cost-effective materials like our cast iron (CI) or ductile iron (DI). Then, we apply a specialized lining to the inside. This gives you the best of both worlds: the mechanical strength of iron and the chemical resistance[^7] of an advanced polymer or rubber.

This is our specialty as an OEM/ODM manufacturer. A customer might come to us needing a valve for a concentrated acid at a specific temperature. We can analyze their needs and recommend the perfect combination. For extreme chemicals, a PFA or PTFE lining is ideal. For abrasive slurries[^5] like those in mining or power plant flue gas desulfurization, a thick, tough natural rubber lining[^8] is the answer.

Here’s a quick guide to how we match materials to the job:

| Lining Material | Best For | Industry Example |

|---|---|---|

| PTFE / PFA | Strong Acids, Bases, Solvents | Chemical Processing Plants |

| EPDM Rubber | Water Treatment Chemicals, Alkalis | Wastewater Treatment |

| Natural Rubber | Abrasive Slurries, Mine Tailings | Mining, Power Plants (FGD) |

The smooth, open flow path of a weir-style diaphragm valve^9[^1] also helps. It minimizes turbulence and prevents abrasive particles from getting trapped, which reduces wear and tear. It’s a complete system designed for survival in the harshest environments.

Is a Diaphragm Valve Really That Simple to Maintain?

Taking a valve offline for complex repairs is time-consuming and expensive. Production stops, and you often need specialized technicians to come in and painstakingly rebuild the valve's internals.

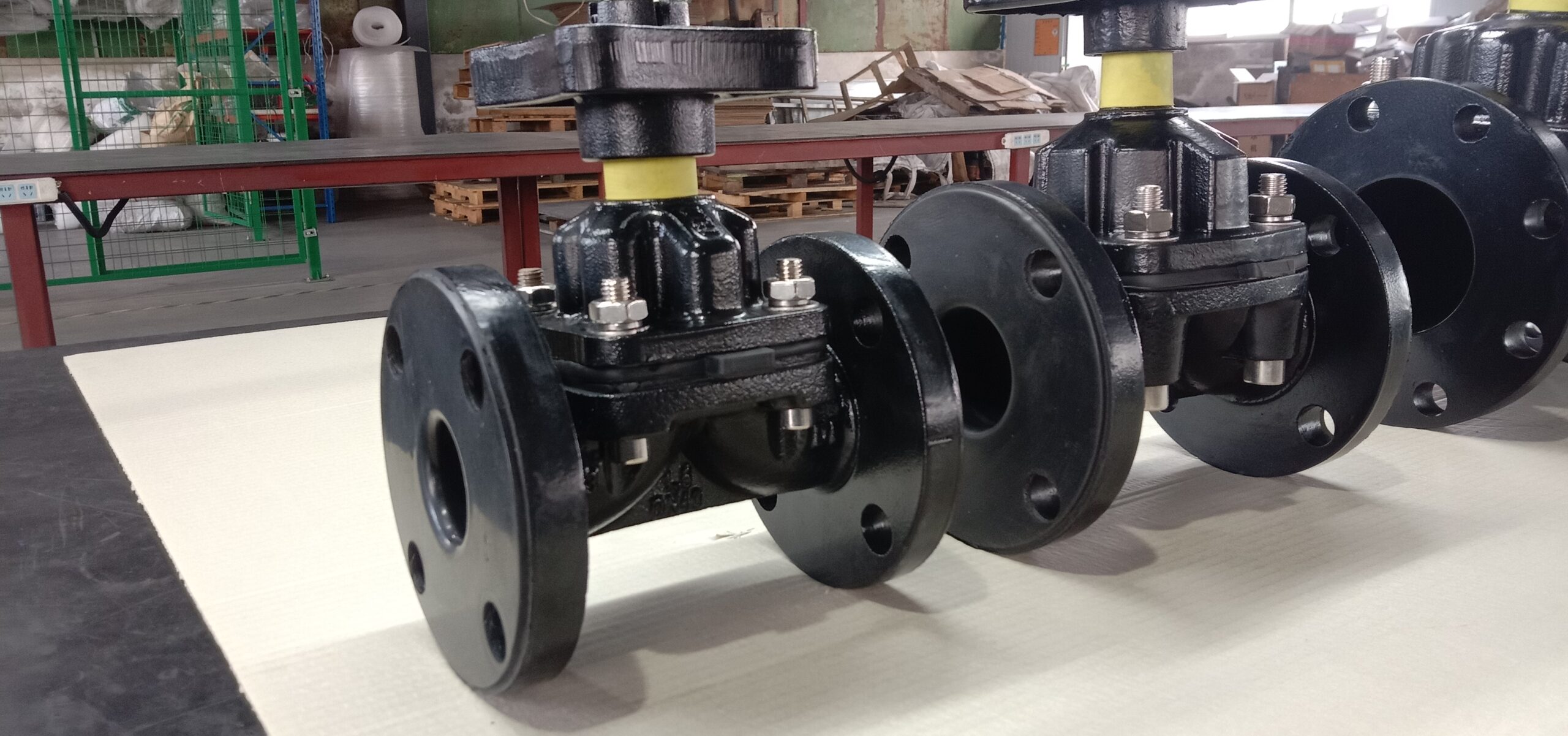

Yes, it's incredibly simple. The diaphragm valve[^1] consists of just three main sections. Since the diaphragm is the main wear part, maintenance usually just means replacing it. This can be done quickly, on-site, often without even removing the valve body from the pipeline.

The maintenance process is a dream for any plant manager. You don't need to be a valve expert to do it. The entire operation can be done in minutes. You simply isolate the valve, unfasten the bolts holding the bonnet to the body, and lift the whole bonnet assembly off. The old diaphragm comes off with it. You put a new one in place, re-secure the bonnet, and you're back in service.

I've had clients tell me they schedule diaphragm changes during a short break. Compare that to the process for a traditional valve, which might involve cutting out gaskets, repacking a leaky gland seal, or trying to re-lap a damaged seat inside the valve body. With a diaphragm valve[^1], all the wetted "internals" are replaced with the new diaphragm. It makes the valve perform like new again. This massive reduction in downtime is a huge financial benefit. The only real trade-off is the temperature limitation, which is dictated by the diaphragm material—usually between -50°C and 175°C. But for the applications it's designed for, this simplicity is an unbeatable advantage.

Conclusion

The diaphragm inventor's genius was the diaphragm itself. This created a leak-proof, corrosion-resistant, and simple-to-maintain valve, making it the perfect solution for tough industrial fluid handling jobs.

[^1]: Explore the unique benefits of diaphragm valves that make them ideal for various industrial applications. [^2]: Learn how leak-proof designs enhance safety and efficiency in industrial fluid handling. [^3]: Discover how a flexible diaphragm contributes to the performance and reliability of valves. [^4]: Find out more about stem leaks and how to prevent them in valve systems. [^5]: Learn how diaphragm valves are designed to manage abrasive slurries in tough environments. [^6]: Explore the top materials used for corrosion resistance in valve manufacturing. [^7]: Find out which materials provide superior chemical resistance for industrial valves. [^8]: Discover how natural rubber linings enhance the performance of valves in harsh conditions. [^9]: Explore the features and advantages of weir-style diaphragm valves in fluid handling.