1. The valve can be installed on the flange only after the flange is welded to the pipe and cooled to ambient temperature. Otherwise, the high temperature generated by welding will affect the performance of the elastic valve seat.

2. The edge of the welding flange must be machined with a lathe until the surface is smooth to avoid damaging the elastic valve seat during valve installation. The flange surface must be completely free from damage and deformation, remove all dirt, dust and foreign matter, and avoid liquid leakage from the valve and flange interface.

3. Clean the flange and the inner cavity of the pipe to thoroughly remove the splashes, scales and other foreign objects left by welding.

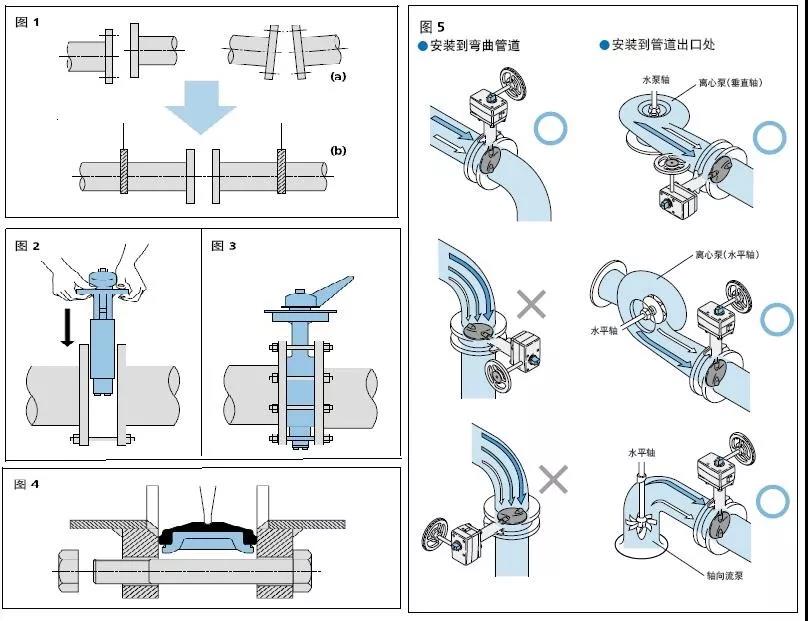

4. When installing pipes between valves, accurately aligning the center of the upper and lower water pipes is essential for trouble-free operation. The inaccurate center point shown in Figure 1 must be avoided.

5. When installing the valve, set the positioning bolts under the pipeline at the same height for support, and adjust the distance between the flanges until the two sides of the valve body are about 6-10 mm apart. Remember here that the valve can only be opened from the closed position to the 10° position.

6. Insert the two bolts into the lower guide rod of the valve, and then install them carefully so that the flange surface will not damage the elastic valve seat. (See picture 2)

7. Then place the other two bolts in the guide rod above the valve to ensure accurate centering between the pipe and the valve.

8. Open the valve three times to check whether the contact between the valve plate and the flange is not smooth.

9. Remove the positioning bolts, place all the bolts around the valve body and tighten them diagonally (see Figure 3 and Figure 4) until the flange touches the valve body. Please refer to the following table for the recommended torque value.

10. When installing the actuator, provide a support for the valve to avoid distortion of the valve neck and reduce friction between the valve and the pipeline.

11. Do not step on the valve neck or valve handwheel.

12. Do not install DN350 or larger valves upside down.

13. Do not install the butterfly valve directly on the check valve or pump, as this may cause damage when contacting the valve plate.

14. Do not install the valve on the downstream side of the elbow and reducer, or calibrate the valve when the flow rate changes. When this happens, it is recommended to install the valve at a distance of approximately 10 times the nominal diameter of the valve.

15. When installing the valve, it is necessary to consider which valve plate will withstand the flow rate and pressure in the process of conveying liquid.