Choosing the wrong valve leads to costly downtime. A small mistake in selection can halt your entire production line. But picking the perfect diaphragm valve[^1] is simple when you know what to look for.

To choose the right diaphragm valve[^1], you must check five things. Consider the valve's internal design, its wear and corrosion resistance, its temperature and pressure limits, and its ability to prevent issues like flashing and cavitation. This ensures you get a reliable valve that lasts.

These five points are the foundation for a reliable fluid control system. But to truly make the best choice, we need to look at each one more closely. A deep understanding of these factors will save you a lot of trouble later on. Let's start with what’s inside the valve, because the design is more important than many people think.

How Does Valve Design Affect Performance?

Have you ever seen a valve fail even when the material seemed right? The internal design was likely the problem. It caused flow issues and put unnecessary stress on the components. The key is matching the valve's internal structure to your specific fluid.

The valve's internal design, especially the shape of its core, is critical. We design it based on the fluid's properties and the forces at play. This ensures smooth flow, precise control, and prevents premature failure. It is the foundation of a reliable valve.

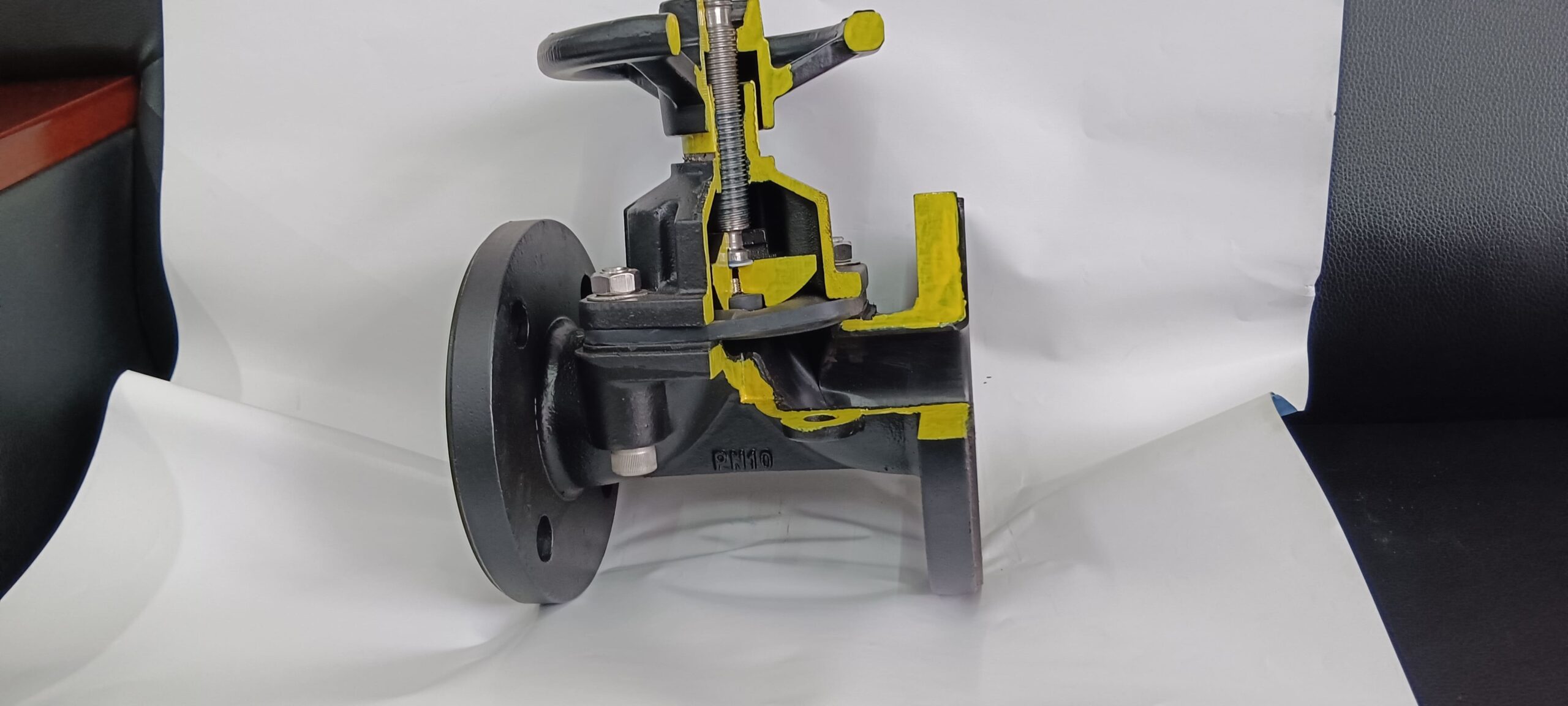

When we talk about diaphragm valve[^1] design, we are mainly talking about two types: weir-type and straight-through. The choice between them depends entirely on your fluid. A weir-type valve[^2] has a raised "weir" or dam inside the body. The diaphragm only has to travel a short distance to close on the weir, which gives you very precise flow control. This design is excellent for clean or slightly corrosive liquids. I remember a client who needed exact dosing for a chemical process. The weir-type valve[^2] gave them the control they needed. The straight-through design[^3], on the other hand, has a smooth, unobstructed flow path. This makes it perfect for fluids with suspended solids, like slurries or sludge, because there is nothing for the material to build up on. Choosing the wrong one can lead to clogging or poor control, so this first step is vital.

| Design Type | Best For | Key Advantage |

|---|---|---|

| Weir-Type | Clean liquids, precise control | Shorter stroke, excellent throttling |

| Straight-Through | Slurries, viscous fluids | Unobstructed flow, less clogging |

Is Your Valve Tough Enough for Abrasive Fluids?

Abrasive slurries can shred a standard valve's internals in no time. This leads to constant replacements, downtime, and high maintenance costs. The solution is a valve built specifically for wear resistance, with a hard lining and a smooth flow path[^4].

For abrasive fluids, wear resistance is the most important factor. The valve must have a smooth flow path to reduce friction. Its internal materials must be tough enough to withstand constant abrasion. Every time the valve closes, it's a battle against wear.

When your fluid contains abrasive particles like sand, grit, or mineral slurry, it acts like sandpaper inside your valve. This is especially true at the point where the valve closes, the seating surface. Each cycle grinds away at the material. That's why two things are incredibly important. First, the flow path must be as smooth as possible. At our factory, we use a resin-coated sand casting process for our valve bodies. This creates a much smoother internal surface than traditional methods, which reduces turbulence and friction. Second, the lining material must be tough. For highly abrasive applications, like in mining or power plant ash handling, a hard natural rubber lining[^5] is often the best choice. It’s durable and resilient. Our mechanically applied linings[^6] create a seamless surface, which further eliminates spots where wear can concentrate. Getting this right means your valve will last for years instead of months.

How Do You Stop Corrosion Before It Starts?

Corrosive chemicals can eat away at a valve and cause dangerous leaks. A single leak can shut down your operations and create a safety hazard for your team. Choosing the right corrosion-resistant lining is the most effective way to protect your system.

When dealing with corrosive fluids, simplicity and material choice are key. We select a valve with a simple structure and a lining made to resist your chemicals. This isolates the corrosive media from the valve body, ensuring long-term, leak-free operation.

The great thing about a diaphragm valve[^1] is its inherent design. The diaphragm isolates all the moving parts from the fluid, so the main valve body and bonnet are already protected. The real battle against corrosion happens at the lining. The lining is the only part that touches the corrosive media. So, the choice of lining material is everything. You don't need a complex valve made from an exotic alloy. A simple, reliable cast iron or ductile iron body with the right lining is often a better and more cost-effective solution. For example, a PTFE or PFA lining is excellent for handling strong acids and solvents in a chemical plant. For water treatment applications where you might use sodium hypochlorite, an EPDM rubber lining[^7] is a perfect choice. We’ve helped many customers simplify their systems by replacing complex metal valves with our correctly lined diaphragm valve[^1]s. They work better and cost less to maintain.

| Lining Material | Best For | Common Applications |

|---|---|---|

| PTFE / PFA | Strong acids, solvents, bases | Chemical processing, pharmaceuticals |

| EPDM Rubber | Water, alkalis, some acids | Water treatment, power plants |

| Natural Rubber | Abrasive slurries, some acids | Mining, wastewater |

Can Your Valve Handle the Heat and Pressure?

High temperatures and pressure changes can cause valve materials to warp or fail. This can lead to seat leakage, loss of control, and potentially a major failure. You need a valve built with materials that remain stable under your specific operating conditions.

When fluid temperature and pressure are high or change often, the valve's materials matter most. The body, diaphragm, and lining must not expand, contract, or deform easily. This ensures a tight seal and reliable performance, no matter the conditions.

Temperature and pressure are a team. You can't consider one without the other. A material that works great at room temperature might fail at 100°C. For example, some rubber linings can get too soft when hot, which can prevent a tight seal. Similarly, high pressure puts a lot of stress on the valve body and the diaphragm. Our valve bodies are made from cast iron and ductile iron, which are very strong and handle pressure well. But the real key is matching the lining and diaphragm materials to the job. Every material has a pressure-temperature (P-T) rating. We always ask our clients for their operating conditions so we can recommend the right combination. For instance, a PFA-lined valve can handle higher temperatures than many rubber-lined valves. A client once had a problem with valves leaking in a hot process line. We found their current valve's lining was not rated for the temperature. We supplied a valve with the correct high-temperature lining, and the problem was solved immediately.

What Are Flashing and Cavitation, and How Do You Avoid Them?

Do you hear strange vibrations or noises coming from your liquid pipelines? That could be flashing or cavitation. These are destructive forces that can destroy your valve from the inside out. Understanding and preventing them is crucial for your valve's longevity.

Flashing and cavitation are destructive issues that only happen with liquids. They occur when pressure drops inside the valve, causing bubbles to form and collapse violently. This creates noise and vibration and can quickly erode valve parts, shortening its life.

Let me explain these two problems simply. Both happen when the pressure of a liquid drops below its vapor pressure as it passes through the valve. This causes the liquid to boil and form vapor bubbles. With flashing, the pressure downstream stays low, so the bubbles remain as vapor. This creates a two-phase flow that can be noisy and erosive. With cavitation, the pressure recovers downstream, and the vapor bubbles violently collapse back into liquid. This collapse creates tiny, high-pressure shockwaves that act like a hammer, chipping away at the valve's internals. Cavitation is extremely destructive and can ruin a valve very quickly. The smooth, linear flow path of a diaphragm valve[^1], especially a straight-through type, helps minimize the sharp pressure drops that cause these problems. By properly sizing the valve for the application, we can design a system where the pressure never drops low enough for these damaging bubbles to form.

| Phenomenon | Description | Primary Damage |

|---|---|---|

| Flashing | Liquid turns to vapor and stays vapor | Erosion from high-velocity vapor/liquid mix |

| Cavitation | Vapor bubbles form, then collapse violently | Pitting and erosion from shockwaves |

Conclusion

Choosing the right diaphragm valve[^1] is about matching its design, materials, and durability to your fluid, pressure, and temperature. Follow these five steps for reliable, long-lasting performance in your system.

[^1]: Understanding diaphragm valves is crucial for selecting the right one for your application. [^2]: Find out why weir-type valves are preferred for precise flow control. [^3]: Learn how straight-through designs minimize clogging and enhance flow. [^4]: Learn how a smooth flow path reduces wear and enhances valve efficiency. [^5]: Discover the applications and benefits of natural rubber linings. [^6]: Learn about the benefits of mechanically applied linings for valve longevity. [^7]: Understand the advantages of EPDM rubber in various fluid applications.