Choosing the wrong valve for flow control can lead to system damage and inefficiency. This mistake costs you time and money. Understanding key differences is crucial for making the right choice.

For precise flow control, or throttling, a diaphragm valve[^1] is almost always the better choice. Its design provides linear regulation and protects internal parts from the media. A standard ball valve[^2] is built for simple on/off service and can be damaged by throttling.

So, you might be wondering why a ball valve[^2] isn't the perfect tool for every job. After all, it's one of the most common valves out there. The answer lies in the design and what happens inside the valve when you try to control flow. Let's break down the mechanics of each valve to see why one is a clear winner for regulation.

Can You Really Use a Ball Valve for Flow Control?

A customer might insist on using a ball valve[^2] for throttling, thinking it's a simple fix. This puts you in a tough spot, worrying about seat damage[^3] and poor performance. Let's look at why this is risky and what the limitations are.

Yes, you can technically use a ball valve[^2] to control flow, but it's not a good idea with standard models. They are designed for on/off duty. Using one to throttle flow often leads to rapid seat erosion and poor control, compromising the valve's ability to seal tightly.

I get this question more often than you'd think. A client will call and say, "We want to use an electric ball valve[^2] with a positioner to regulate our line." On the surface, it seems like a straightforward request. However, the fundamental design of a standard ball valve[^2] makes it a poor choice for this task. It’s a quarter-turn valve with a hole through the center. When it's fully open, the flow path is clear. When it's closed, the solid part of the ball blocks the flow. The problem arises when it's partially open.

Why Standard Ball Valves Fail at Throttling

When you partially open a ball valve[^2], you create a narrow, crescent-shaped opening. The fluid is forced through this small gap at very high velocity. This high-speed jet of fluid smashes directly against the soft seats, typically made of PTFE. This effect, known as "wire drawing," quickly erodes the seat material. Once the seat is damaged, the valve can no longer provide a bubble-tight shutoff when you need it to close completely. The flow characteristic is also non-linear, meaning a small turn near the closed position causes a huge change in flow, while a turn near the open position does very little. It’s more like a light switch than a dimmer.

The Exception: V-Port Ball Valves

To be fair, there is a type of ball valve[^2] made for control: the V-port ball valve[^2]. These have a V-shaped notch cut into the ball. This design creates a more predictable and linear flow characteristic, making it much better for throttling applications. However, they are more complex and expensive than standard ball valve[^2]s. For many industrial applications, especially with corrosive or abrasive fluids, a diaphragm valve[^1] still offers a more robust and cost-effective solution.

| Feature | Standard Ball Valve | V-Port Ball Valve |

|---|---|---|

| Primary Use | On/Off (Isolation) | Throttling (Control) |

| Control Accuracy | Poor | Good |

| Seat Wear in Throttling | High | Low |

| Flow Characteristic | Non-linear (Quick Opening) | More Linear / Equal Percentage |

| Cost | Lower | Higher |

What Makes a Diaphragm Valve a Superior Choice for Regulation?

You need precise, reliable control over corrosive or abrasive fluids. But standard valves often leak, corrode, and fail, causing downtime and safety hazards. The unique design of a diaphragm valve[^1] offers the perfect solution for these tough control applications.

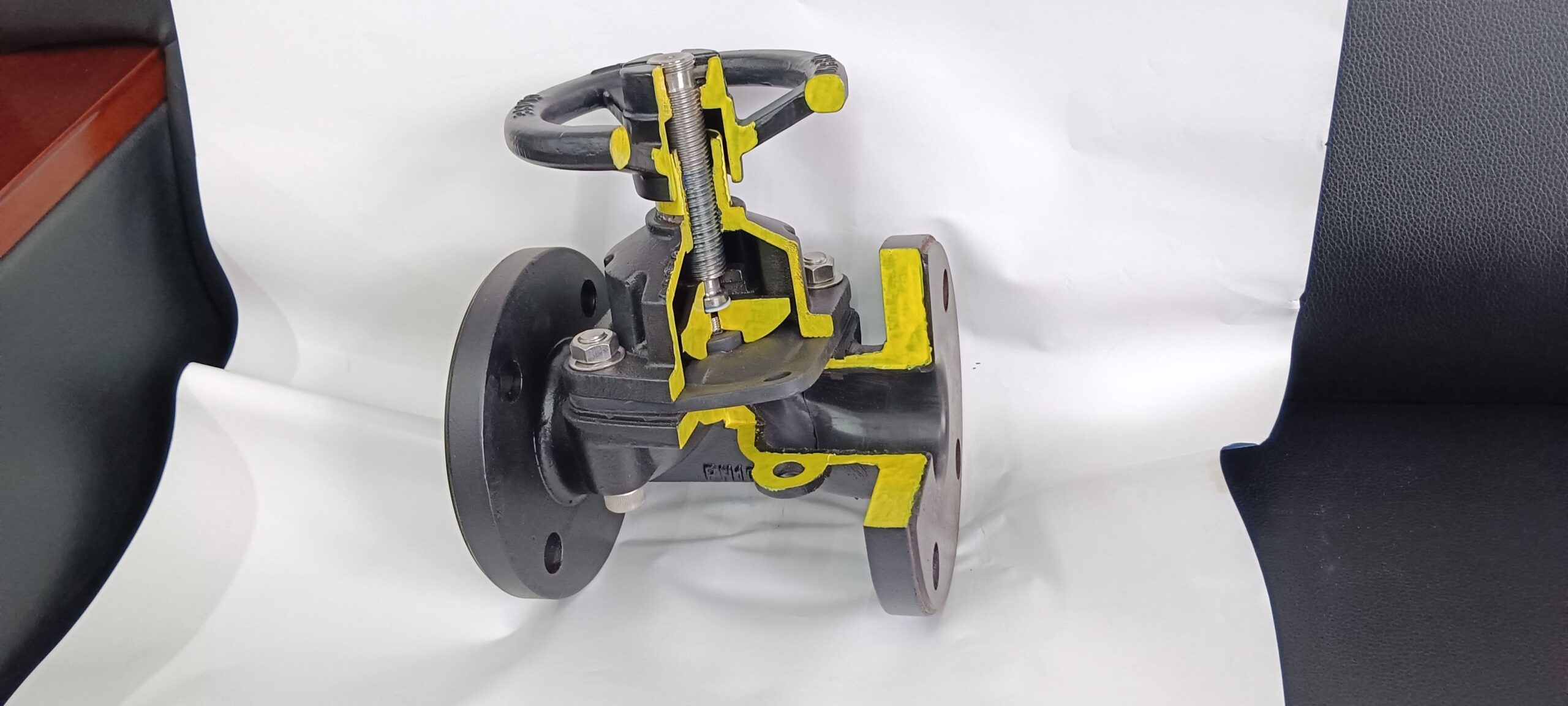

A diaphragm valve[^1] excels at regulation because its flexible diaphragm provides a linear flow response and bubble-tight shutoff. The media is completely isolated from the valve's moving parts, preventing corrosion and contamination, making it ideal for aggressive or sensitive fluids.

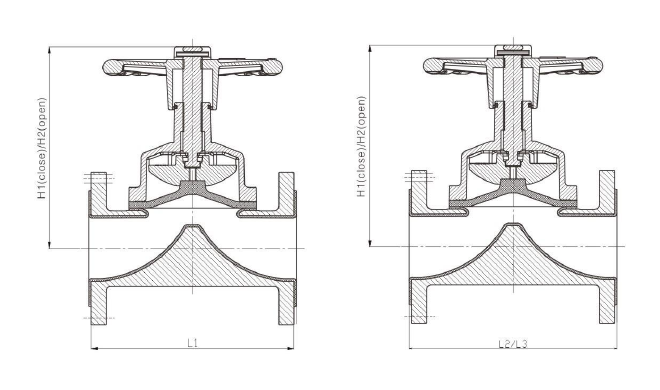

From my experience as a manufacturer, the diaphragm valve[^1] is a purpose-built regulating valve. It's designed from the ground up to handle jobs that other valves struggle with. Think of it as a special type of globe valve. Its closing part is a soft, flexible diaphragm. This simple difference gives it several powerful advantages, especially in the chemical, power, and wastewater treatment[^4] industries we serve.

Key Advantages in Flow Control

A diaphragm valve[^1] works by pressing a flexible diaphragm down onto a weir (a ridge in the valve body). The distance the diaphragm travels directly and proportionally controls the flow rate. This creates a very linear and predictable flow characteristic, which is exactly what you need for precise regulation. It’s a true dimmer switch for fluid flow.

The most important feature is media isolation. The diaphragm creates a perfect seal that separates the fluid from all the working parts of the valve—the stem, the bonnet, and the actuator. This means corrosive chemicals or abrasive slurries never touch the parts that make the valve operate. This prevents corrosion, eliminates the need for stem packing, and ensures the fluid never gets contaminated by lubricants or outside particles.

Because there is no stem passing through the pressure boundary, there is no need for gland packing. This glandless design completely eliminates the possibility of external leakage from the stem, which is a common failure point in other valve types.

Low Maintenance and Cost-Effectiveness

Finally, maintenance is incredibly simple and low-cost. The only wetted parts are the valve body lining and the diaphragm itself. When a diaphragm eventually wears out, you don't need to replace the entire valve. You just unbolt the bonnet, swap in a new diaphragm, and put it back together. The valve is back in service in minutes, often without even needing to be removed from the pipeline. We had a client in a chemical plant[^5] who switched to our PFA-lined diaphragm valve[^1]s for an acid dosing line. Their old valves failed every few months. With our valves, they now only perform maintenance[^6] every two years, saving them thousands in downtime and parts.

Conclusion

For simple on/off service, a ball valve[^2] works well. But for precise flow control, especially with tough fluids, the diaphragm valve[^1] is the superior choice, offering reliability and long-term value.

[^1]: Explore the benefits of diaphragm valves for precise flow control and media isolation, crucial for various industries. [^2]: Discover why ball valves may not be suitable for flow regulation and the risks involved. [^3]: Understanding seat damage can help in selecting the right valve and avoiding costly repairs. [^4]: Learn about the critical role of valves in managing wastewater treatment systems effectively. [^5]: Find out which valves are most effective for chemical processing and why diaphragm valves excel. [^6]: Learn about the low maintenance needs of diaphragm valves and how they save costs over time.